FAQs

Find answers to common questions about Kenwei's weighing packing machines. Learn more about our multihead weighers, check weighers, packing machines, and food packaging solutions to enhance your production efficiency.

FAQs about weighing and packing machines

Our weighing and packing industry FAQ page covers common questions regarding the cooperation process, product selection, custom services, solution recommendations, logistics, delivery, and after-sales support. We are committed to providing comprehensive and detailed information to help you better understand our products and services, as well as how to best meet your needs for weighing and packing product collaboration.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

About products customization

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

About Solution suggestions

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

How about the after-sales service?

Warranty :2 years

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

More Popular Products

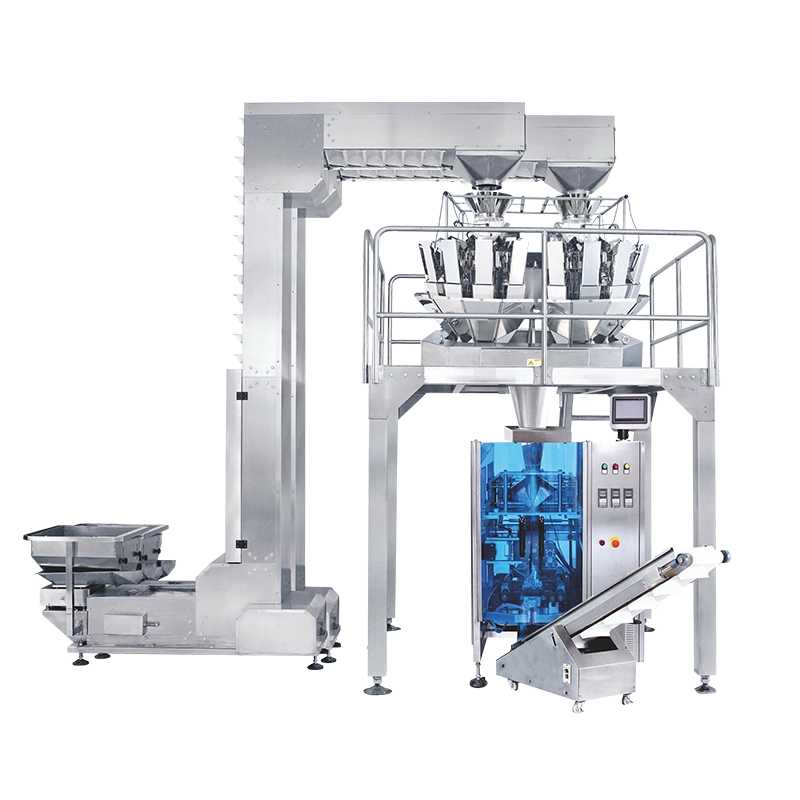

The Kenwei JW-B26 Single Multihead Weigher Mixing and Packaging System offers fully automated operation, completing feeding, weighing, filling, date printing, and product output with high accuracy and speed. Ideal for granules, slices, irregular shapes, and mixed products like candy, nuts, snacks, pet food, and even small hardware. Its versatility and precision make it a perfect solution for diverse packaging needs.

The Kenwei JW-B26 Single Multihead Weigher Mixing and Packaging System offers fully automated operation, completing feeding, weighing, filling, date printing, and product output with high accuracy and speed. Ideal for granules, slices, irregular shapes, and mixed products like candy, nuts, snacks, pet food, and even small hardware. Its versatility and precision make it a perfect solution for diverse packaging needs.

The Kenwei JW-B22 Precision Food Packaging Machine with Single Head Bulk Linear Weigher is designed for heavy-duty weighing up to 50kg. It automates feeding, weighing, bag sewing, and output for maximum efficiency. Ideal for grains like corn, rice, soybeans, barley, and wheat, it ensures high accuracy and reliability for the food, chemical, and light industries, making it the top choice for bulk grain packaging.

The Kenwei JW-B20 Semi-Automatic Multi-Function Packaging Machine with Linear Weigher is ideal for powders and granules like sugar, salt, rice, coffee, and milk powder. It automates feeding, weighing, and output with high accuracy and efficiency. Compact and cost-effective, it suits various bag types not supported by standard machines, making it perfect for flexible, space-saving packaging needs.

The Kenwei JW-B18 Two-Outlet Semi-Auto Weighing and Packing System with Vacuum Feeding is ideal for weighing powders and regular-shaped granules such as coffee, sugar, rice, salt, and milk powder. It offers fully automatic feeding, weighing, and bag filling with high accuracy and speed. Compact and cost-effective, it supports bag types unsuitable for standard machines, making it perfect for space-limited and budget-conscious operations.

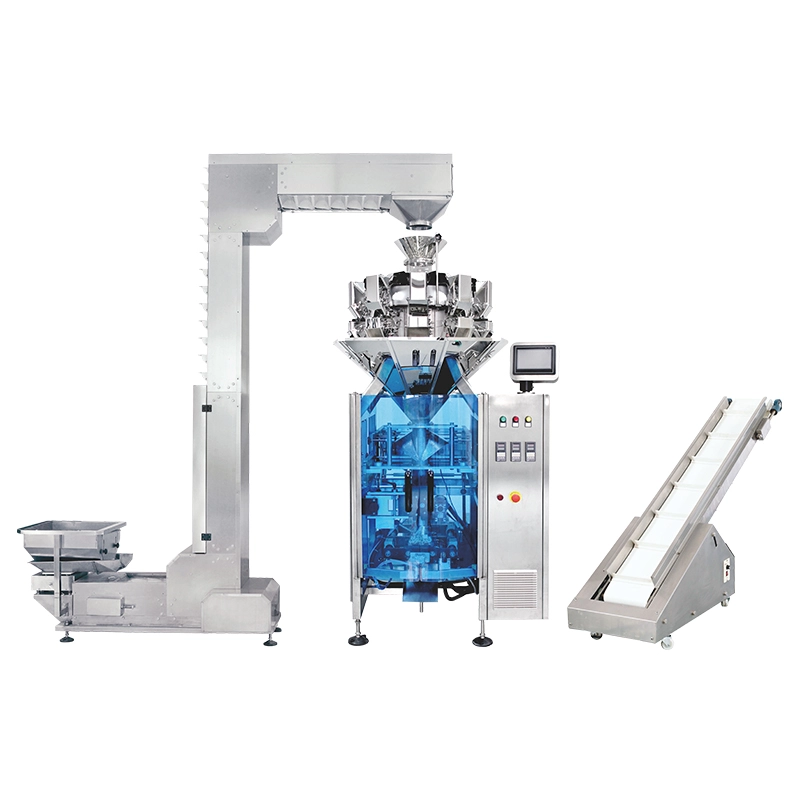

The Kenwei JW-B17 Two-Outlet Semi-Auto Weighing and Packing System with Inclined Conveyor offers precise, efficient weighing for granules, slices, and irregular items like candy, peanuts, pet food, and small hardware. Its fully automated operation boosts productivity, while the compact design saves space and reduces costs. Compatible with various bag types, this cost-effective system includes optional chain plate or belt inclined conveyors for flexible material handling.

The Kenwei JW-B16 Two Outlet Semi-Auto Sugar Weighing and Packaging Machine delivers high-precision, automated weighing for granules, slices, and irregular products like candy, coffee beans, and pet food. With a compact, cost-effective design and excellent price-performance ratio, it supports unique bag types and boosts efficiency. Optional add-ons like check weighers, metal detectors, and conveyors ensure quality control and seamless integration. Ideal for food and hardware industries.

The JW-B14 double inlet pre-made bag packing machine offers a fully automatic solution for feeding, weighing, filling, date printing, and output. With high speed and ±0.1g accuracy, it supports a wide range of products—granules, slices, irregular shapes like candy, coffee beans, pet food, and more. Designed for pre-made bags, it ensures stable performance, efficient production, and attractive bag appearance.

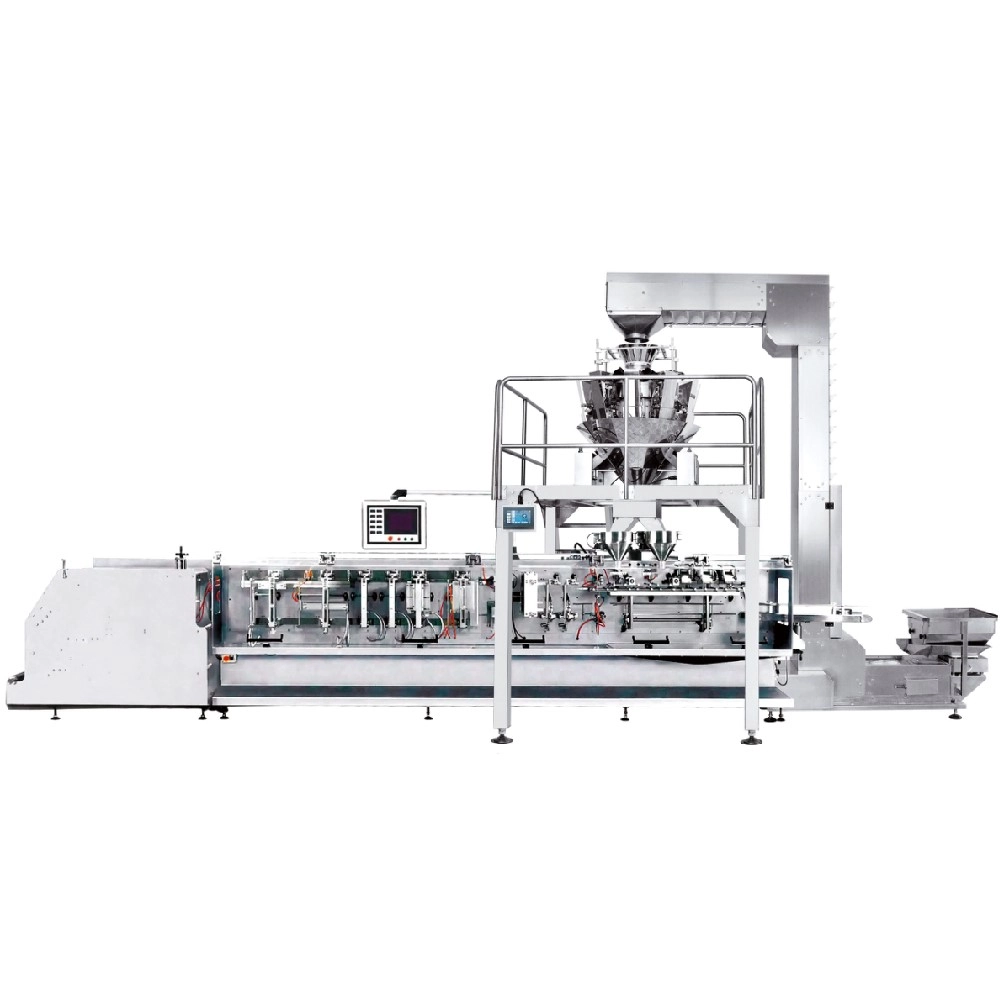

The JW-B12 Double Feeder Horizontal Packaging and Weighing System is designed for high-speed, high-precision packaging of snacks, puffed foods, nuts, candies, hardware, and irregular-shaped materials. With a multihead weigher and dual-feeder setup, it delivers efficient, fully automated feeding, weighing, and bagging for a wide range of products—ensuring secure seals and professional premade bag packaging.

Horizontal Packaging Machine With Multihead Weigher for Weighing Pet Foods Puffy Foods B11 is a fully automatic solution for high-speed, high-accuracy packaging. Ideal for snacks like candy, jelly, nuts, and puffed food, as well as hardware and plastic granules in various shapes. It supports premade bags with firm, attractive sealing. Designed for customers needing high production efficiency and large output capacity.

The JW-B10 Rotary Vacuum Packaging and Weighing System integrates a vibrator feeder, Z bucket conveyor, multi-head weigher, and rotary vacuum packaging machine. It offers high-precision, fully automatic feeding, weighing, vacuum sealing, and output. Ideal for snacks, puffed foods, hardware, and plastic granules, it uses premade bags and delivers excellent vacuum sealing—perfect for products requiring long-lasting freshness.

The JW-B7 Economical Linear Weighing and Vertical Packaging Machine is ideal for packaging small granules and powder materials such as sugar, salt, rice, sesame, milk powder, coffee, and seasoning powder. This compact, cost-effective system automates feeding, weighing, filling, and bagging with date printing and output. It reduces labor costs, enhances efficiency, and is perfect for businesses with moderate speed requirements.

The JW-B4 Combined Multihead Weighing and Packaging Machine with Z Conveyor is a compact, fully automatic solution ideal for packing snacks, nuts, candies, pet food, frozen products, hardware, and more. It integrates feeding, weighing, filling, sealing, and labeling with high precision and speed. Suitable for a wide range of materials, it’s perfect for space-limited production lines.

Discover the Kenwei 200g High Precision Food Checkweigher—ideal for accurate weight inspection in food packaging and processing. Our checkweigher ensures reliable results and efficiency. Choose Kenwei checkweighers for advanced quality control solutions.

The JW-C30000 sorting checkweigher is designed to move products using conveyor belts or rollers, ensuring accurate weight control in manufacturing and packaging lines. This high-precision checkweigher automatically verifies whether each product falls within the specified weight range, helping to eliminate underweight or overweight items before they reach the market.

With a maximum inspection weight of 30 kg, it offers a wide weighing range, high speed, and consistent accuracy. Ideal for bulk paper bags, plastic bags, cartons, metal film packaging, and other rigid packages, this checkweigher system supports both belt and roller transport options. As a reliable tool for quality assurance, it provides stable performance and is widely used across various industries for efficient weight checking.

Discover the Kenwei Automatic 1000g Belt Conveyor Checkweigher, designed for accuracy in the food industry. This advanced checkweigher system ensures precise weight control, while the robust checkweigher conveyor supports efficient production lines.

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

Kenwei Inclined Belt Conveyor is ideal for efficient packing lines. As a leading Inclined Conveyor, Inclined Belt Conveyor, and Inclined Chain Plate Conveyor, it ensures smooth material transport, improves workflow, and boosts productivity in industrial operations.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei