Weighing And Packing Systems For Pre-made Bag

Discover advanced weighing and packing systems for pre-made bag solutions from Kenwei. Boost efficiency with our reliable packing and weighing machines, perfect for precise food packaging and streamlined production processes.

Weighing And Packing Systems For Pre-made Bag

Characteristic

-

● Fully automated process for finishing, weighing, bag filling, date printing, and finished product output.

● Ensures high precision and maximum efficiency.

● Capable of handling a wide range of materials.

● Delivers stable performance, high-speed operation, and excellent production efficiency, while creating attractive bag packaging.

● Leak-proof sealing and precise filling, significantly enhancing packaging quality, both in terms of material filling and the overall appearance of the bags.

Bag Types: 3-side seal bags, 4-side seal bags, flat bags, flat bags with zipper, vertical zipper bags, custom flat pouches, and special vertical pouches.

Optional equipment

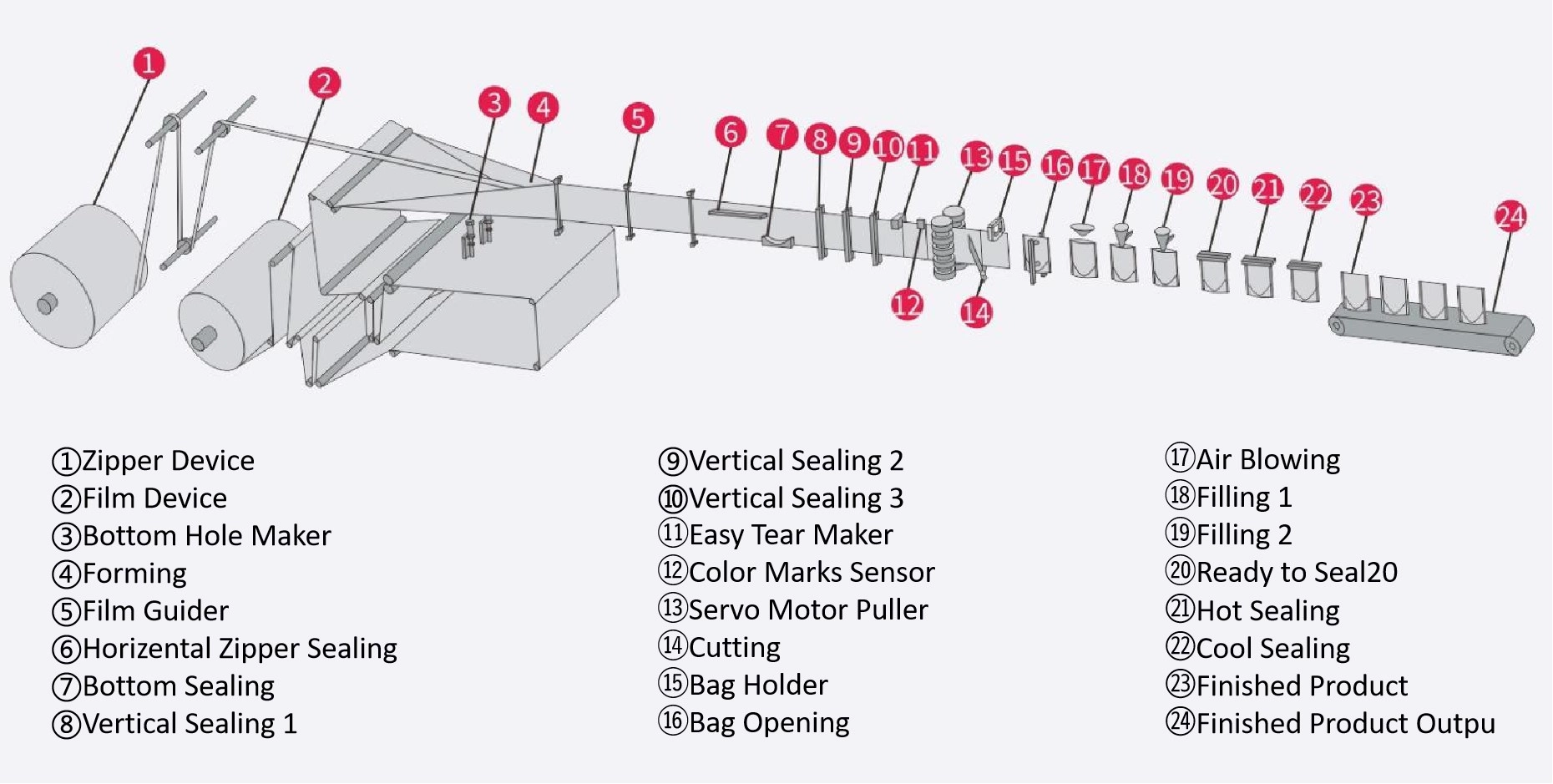

Horizental Pouch Packing Machine Process Flow Diagram

-

The "Horizontal Pouch Packing Machine Process Flow Diagram" is a visual representation that outlines the key stages and sequence of operations in a horizontal pouch packaging system. It typically includes steps like material feeding, weighing, pouch formation, filling, sealing, date printing, and final product discharge. The diagram helps illustrate how raw materials are processed and packaged into finished pouches in a systematic and efficient manner.

Weighing and packing systems with standard, pre-made bag packing machine JW-B13

The system consists of a vibrator feeder, Z conveyor, working platform, multi-head weigher, and horizontal packing machine.

Application

It is ideal for weighing rolled, irregular granules, and sliced products such as candies, seeds, jellies, French fries, coffee beans, peanuts, puffed foods, biscuits, chocolates, nuts, pet food, hardware, and more.

Characteristic

-

● Fully automated process, handling everything from feeding and weighing to date printing and finished product output.

-

● Versatile and suitable for a wide range of materials.

-

● High precision in weighing and exceptional efficiency.

-

● Designed for pre-made bags, offering stable operation, fast speed, high production efficiency, and attractive bagging quality.

Weighing and packing systems with double inlet pre-made bag packing machines JW-B14

The system consists of a vibrator feeder, Z conveyor, working platform, multi-head weigher, and double-inlet horizontal packaging machine.

Application

It is an ideal solution for weighing a variety of products, including granules, slices, rolls, and irregularly shaped items such as candies, seeds, jelly, French fries, coffee beans, peanuts, puffed foods, biscuits, chocolates, nuts, pet food, hardware, and more.

Characteristic

-

● Fully automatic process, covering feeding, weighing, date printing, and finished product output.

-

● Versatile and suitable for a wide range of materials.

-

● Delivers high precision and exceptional efficiency.

-

● Ensures stable operation, high-speed performance, and efficient production with aesthetically pleasing pre-made bags.

Weighing and packing systems with economic pre-made bag packing machine JW-B15

The system includes: a vibrator feeder, Z conveyor, multi-head weigher, double-inlet horizontal packaging machine, and working platform.

Application

It is designed for packaging various products including granules, sliced, rolled, or irregularly shaped items such as jelly, French fries, puffed food, biscuits, candy, seeds, chocolate, coffee beans, peanuts, pet food, hardware, and more.

Characteristic

-

● Fully automated process, including feeding, weighing, date printing, and finished product output.

-

● Suitable for a wide variety of materials.

-

● Delivers high weighing accuracy and exceptional efficiency.

-

● Fast operation, high production efficiency, and attractive packaging for pre-made bags with stable performance.

-

● Cost-effective, space-saving, and ideal for small 3-side and 4-side sealing bags.

Contact Kenwei

Our company is located in a region with convenient transportation and a strong economy, ensuring timely product delivery and fast service. Throughout our operations, we prioritize customer satisfaction and offer quick, responsive support. Have questions or concerns about our products? Leave us a message, and our team will get back to you promptly with efficient solutions.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei