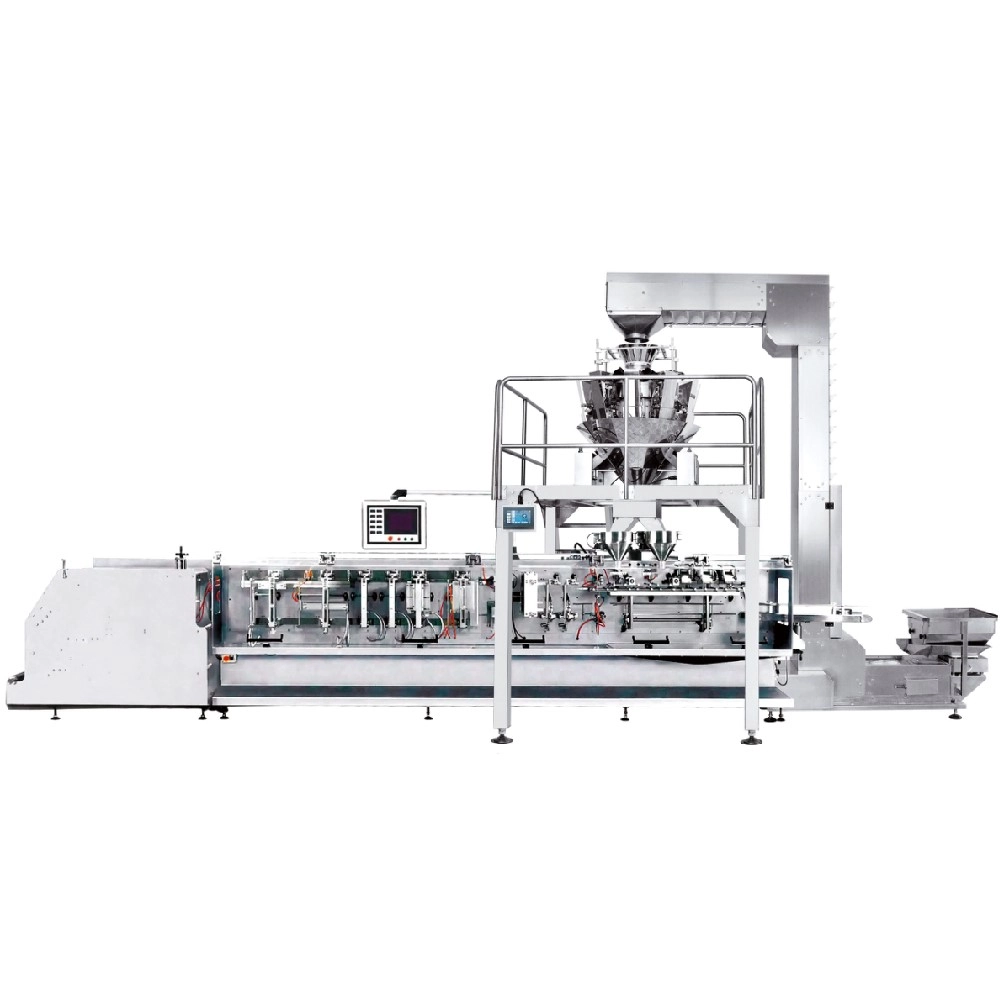

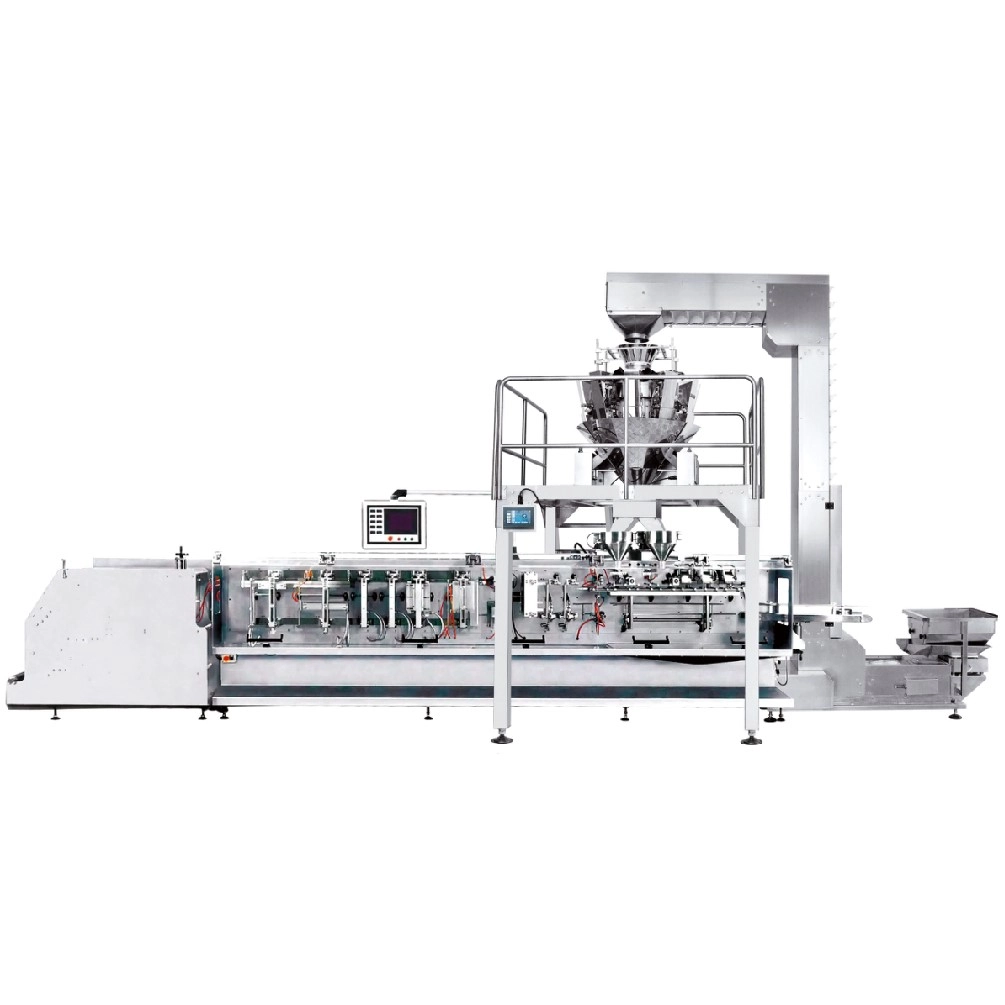

Economic Premade Pouch Weighing And Packing Machine System JW-B15

The Kenwei Economic Premade Pouch Weighing and Packing Machine JW-B15 offers fully automatic feeding, weighing, filling, date printing, and output. With high accuracy, speed, and space-saving design, it’s ideal for small 3-side or 4-side seal bags. Suitable for granules, slices, irregular shapes like candy, nuts, pet food, and small hardware. A cost-effective solution for precise, efficient packaging.

| Supply Ability | 2000sets/year | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 30days |

| Start Port | Zhongshan port | ||

Feature

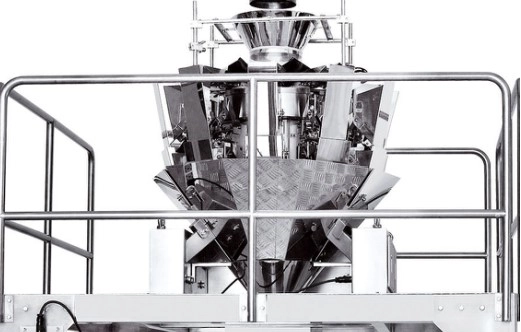

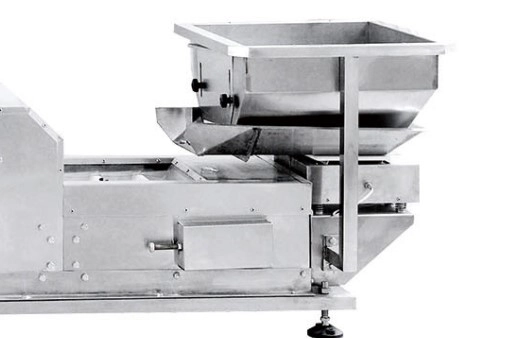

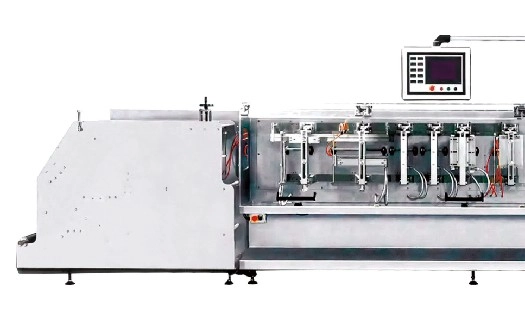

System includes: vibrator feeder, Z conveyor, multi-head weigher, double-inlet horizontal packaging machine, and working platform.

● Fully automatically completes all the processes from feeding, weighing, date-printing, and finished products outputting. The user-friendly touchscreen interface simplifies operation and adjustments.

● Wide scope of application, this premade pouch packaging machine suitable for various materials.

● Built with food-grade materials and stainless steel, it meets hygiene standards and ensures durability. High weighing precision and efficiency.

● Used for the pre-made bag, Stable operation, high speed and high production efficiency, beautiful bag making.

● Cheapness, high price ratio, and space savings; premade pouch filling machine is suitable for small 3-side seal bags and small 4-side seal bags. Its automated filling and sealing processes enhance productivity, processing up to 60 pouches per minute.

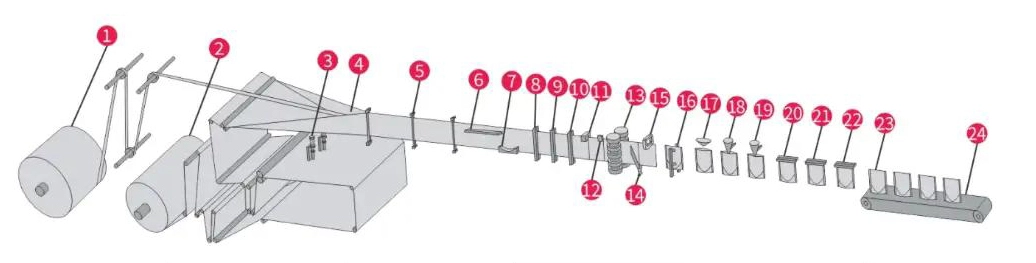

Horizontal Premade Pouch Packing Machine Process Flow Diagram

| 1. Zipper Device | 2. Film Device | 3. Bottom Hole Maker | 4. Forming | 5. Film Guider | 6. Horizontal Zipper Sealing |

| 7. Bottom Sealing | 8. Vertical Sealing 1 | 9. Vertical Sealing 2 | 10. Vertical Sealing 3 | 11. Easy Tear Maker | 12. Color Marks Sensor |

| 13. Servo Motor Puller | 14. Cutting | 15. Bag Holder | 16. Bag Opening | 17. Air Blowing | 18. Filling 1 |

| 19. Filling 2 | 20. Ready to Seal | 21. Hot Sealing | 22. Cool Sealing | 23. Finished Product | 24. Finished Product Output |

Application

It is designed for packaging various products including granules, sliced, rolled, or irregularly shaped items such as jelly, French fries, puffed food, biscuits, candy, seeds, chocolate, coffee beans, peanuts, pet food, hardware, and more.

Bag Type

Include: 3-side seal bag, 4-side seal bag, flat bag, flat bag with zipper, stand-up bag with zipper, special flat bag, and special stand-up bag, and more.

Optional Equipment

It is designed to inspect the weight of packaged bags and boxes, automatically identifying and rejecting any items that do not meet the preset weight standards using a rejection mechanism.

It is widely applied in industries such as food, pharmaceuticals, chemicals, textiles, apparel, toys, and rubber. It is an ideal solution for meeting HACCP standards in the food industry and GMP compliance in pharmaceutical production.

Throat Metal Detector

This equipment is specifically applied for inspecting and detecting powders, granules, and sheet materials. It ensures precise and reliable quality control, making it ideal for use in food, pharmaceutical, chemical, and related industries.

It is widely applied in the food, pharmaceutical, chemical, textile, clothing, toy, and rubber industries. As a top choice for HACCP compliance in the food sector and GMP standards in the pharmaceutical field, it ensures high-level quality control and safety.

Rotary collecting table

Designed for collecting products from the production line, this equipment is ideal for operations requiring manual handling or temporary storage before the next packaging stage. Perfect for improving workflow efficiency in various processing environments.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

About Solution suggestions

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

Double Filling VFFS Packaging Machine for Efficient Dual Product Packaging

6-Head Linear Weigher for Accurate Granule and Powder Weighing

Weighing and packing systems with double inlet pre-made bag packing machines JW-B14

Double Column Check Weigher for Accurate Material Weight Testing and Automatic Sorting

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei