7 in 1 mixing/counting packaging system with 32 head weigher JW-B27

Discover the Kenwei JW-B27 7-in-1 mixing/counting packaging system with a 32-head weigher—your smart solution for efficient counting and packaging. Ideal for food and goods industries needing reliable counting and packaging system performance.

7-in-1 mixing/counting packaging system with 32 head weigher JW-B27

The units: bulk weigher, horizontal belt conveyor, sack closer, inclined conveyor, and vibratory feeder.

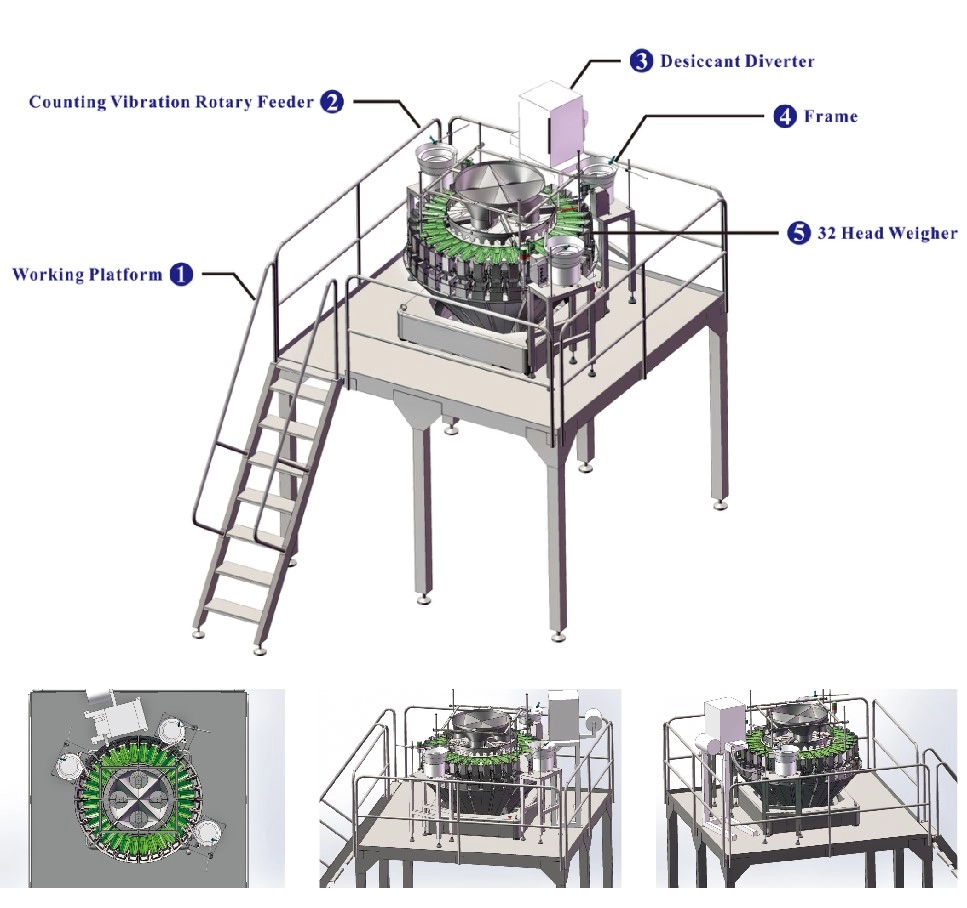

System including

The system features a 32-head weigher, a counting vibration rotary feeder, and a working platform, delivering high efficiency and precision for multi-material weighing and counting tasks. To enhance automation, optional add-ons such as a material feeding conveyor, packaging machine, and desiccant feeder can be seamlessly integrated, forming a complete automated packaging line.

Features

-

● Weighing range: 5–240g

-

● The 32-head weigher offers high combination efficiency, flexible configuration, strong adaptability, and high weighing precision.

-

● The main material intelligently compensates for formula weighing errors to ensure total weight accuracy.

-

● Supports flexible formula mixing with fewer than 7 materials, and allows expansion to more than 7 materials if needed.

-

● Can function as a high-speed weigher for a single material or be used for weighing larger target weights.

● Optional equipment is compatible with standard multihead weigher mixing systems.

Mixing Weighing Configuration

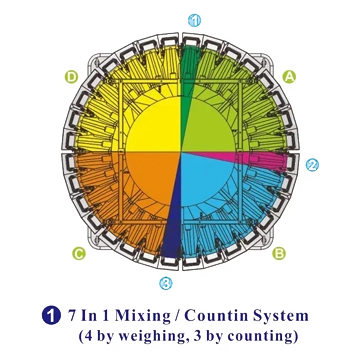

Illustration A: Mixed weighing of 4 materials + 3 kinds of materials counting pieces (total weighing accuracy: ± 1.5g)

The 32-head weigher with distributed hoppers is designed for accurate weighing of four different materials. It features 7 hoppers (±2g) for each of the three secondary materials and 8 hoppers (±1.5g) for the main material. The main material’s hoppers are configured to automatically compensate for any weighing errors from the other materials, ensuring the total weight remains accurate within ±1.5g. The secondary materials are distributed across 7 hoppers each, with a weighing accuracy of ±2g. The system delivers reliable and precise formula weighing performance.

The 32-head weigher for counting three different materials features distributed hoppers with 1 hopper (±0) assigned to each material. Each material is accurately fed into its designated hopper using a high-precision counting vibration rotary feeder, with focus on piece counting rather than weight accuracy.

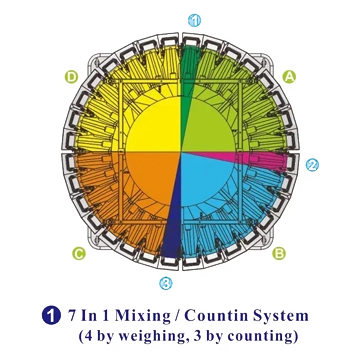

Illustration B: Mixed weighing of 3 materials + 4 kinds of materials counting pieces (total weighing accuracy ± 1g)

The 32-head weigher with distributed hoppers is designed for accurate weighing of three different materials. It features 10 hoppers (±1g) for the main material, which automatically compensates for weighing errors from the other materials to ensure total weight accuracy within ±1g. The remaining two materials are distributed into 10 hoppers (±1g) and 8 hoppers (±1.5g), with a control accuracy of up to ±2g. This system delivers high precision in formula weighing and ensures consistent performance across multi-material applications.

The 32-head weigher for counting four different materials is equipped with distributed hoppers—1 hopper (±0) for each material. Each material is allocated to a dedicated hopper and fed with high precision using a vibrating rotary feeder, ensuring accurate piece counting regardless of weight accuracy.

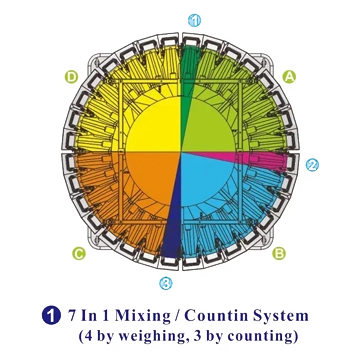

Illustration C: 3 kinds of material high accuracy mixingg + 4 kinds of material low accuracy mixing weighing (total weighing accuracy: ±1g)

High-precision mixed weighing of 3 materials + low-precision mixed weighing of 4 materials (total weighing accuracy: ±1g)

The 32-head weigher with distributed hoppers is specifically designed for high-precision mixed weighing of three different materials. It features 10 hoppers (±1g) for the main material, which automatically compensates for any formula weighing errors to ensure total weight accuracy within ±1g. The other two materials are allocated to 10 hoppers with a control accuracy of ±1g and 8 hoppers with a control accuracy of ±1.5g. This advanced system delivers excellent control over formula weighing, ensuring consistent accuracy and reliable performance.

The 32-head weigher for counting four different materials utilizes distributed hoppers, with 1 hopper (±0) assigned to each material. Each material is fed into its designated hopper with high precision using a counting vibrating rotary feeder, ensuring accurate piece counting regardless of weight accuracy.

Hoppers for counting pieces and hoppers for low-precision weighing can be arbitrarily interchangeable

Contact Kenwei

Our company is located in a region with convenient transportation and a strong economy, ensuring timely product delivery and fast service. Throughout our operations, we prioritize customer satisfaction and offer quick, responsive support. Have questions or concerns about our products? Leave us a message, and our team will get back to you promptly with efficient solutions.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei