Linear Weigher Mixing Weighing/Counting System

Discover Kenwei’s advanced Linear Weigher Mixing Weighing/Counting System, engineered for precision and efficiency. Ideal for food packaging, it enhances productivity and accuracy in your packing line. Optimize your process with our linear weigher solutions.

Linear Weigher Mixing Weighing/Counting System

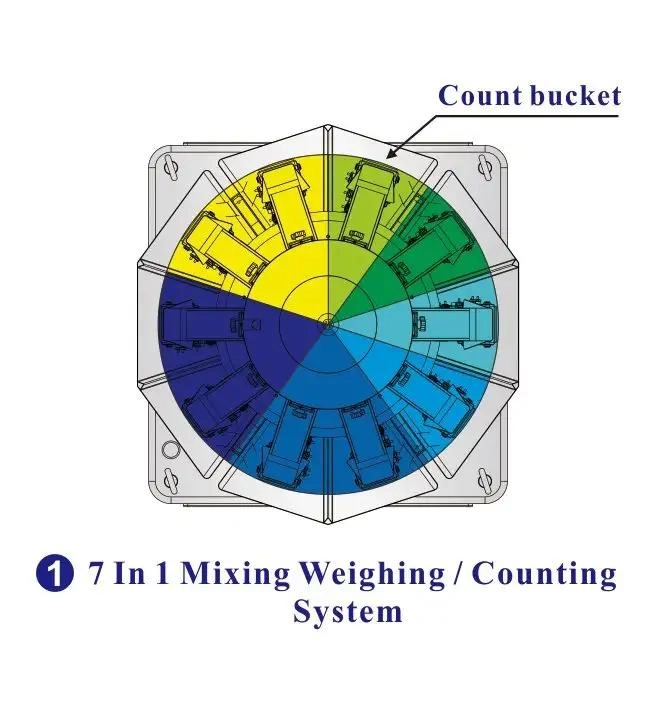

Sample 1: “7 in 1 mixing weighing system” configured as “7 in 1 mixing weighing/counting system”

Configuration: 10-head linear weigher

The total weight of the formula is 5-1400g.

The 10-head linear weigher, designed for six materials, features a hopper distribution of 2 hoppers (±1g) for three materials, and 1 hopper (±1g) for the remaining three materials. This setup ensures that all materials are distributed across the hoppers with a control accuracy of ±1g. The precise formula weighing ensures consistent and accurate results, making it ideal for high-quality packaging applications.

The 10-head linear weigher, designed for counting a single material, utilizes a distributed hopper configuration with one hopper (±0). Each material is allocated to a single hopper and fed with high precision by the vibrating rotary feeder, ensuring accurate counting regardless of weight accuracy. This setup guarantees efficient and reliable material handling for precise counting applications.

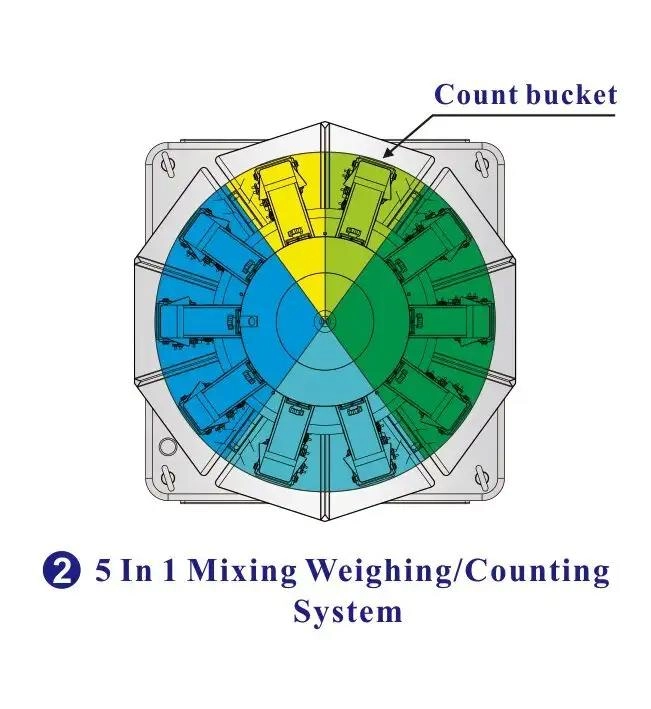

Sample 2: “4 in 1 mixing weighing system” configured as “5 in 1 mixing weighing/counting system”

Configuration: 10-head linear weigher

The total weight of thela is 5-800g.

The 10-head linear weigher, ideal for weighing three materials, features a hopper distribution of 3 hoppers (±1g) for two materials and 2 hoppers (±1g) for the remaining material. Two materials are allocated to three hoppers, ensuring a control accuracy within ±1g, while the third material is distributed in two hoppers with the same accuracy. This configuration maintains precise formula weighing and optimal control over material distribution.

The 10-head linear weigher for counting two materials features a distribution of 1 hopper (±0) for each material. Each material is accurately fed into its respective hopper using a vibrating rotary feeder, ensuring high precision in counting (weight accuracy is not considered). This setup ensures reliable and efficient material handling.

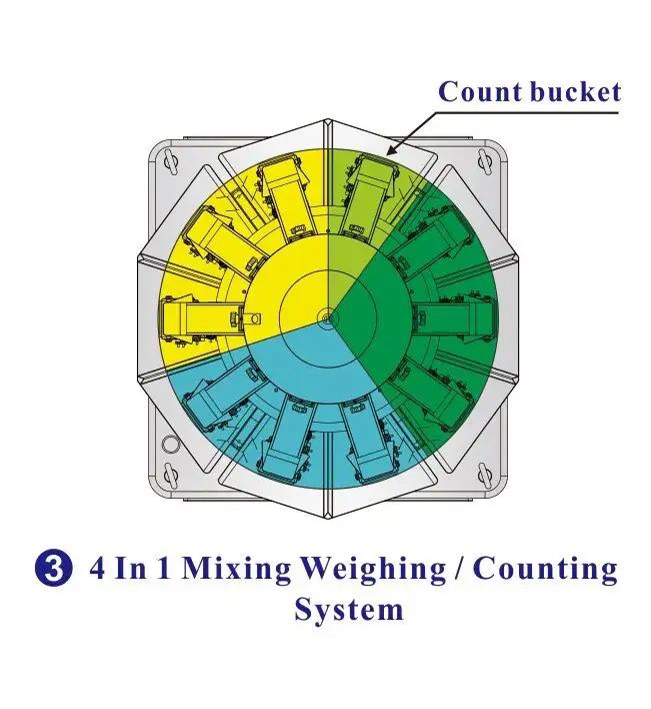

Sample 3: “4 in 1 mixing weighing system” configured as “4 in 1 mixing weighing/counting system”

Configuration: 10 head linear weigher

The total weight of the formula: 5-800g

The distributed hoppers for the 10-head linear weigher designed for 3 materials consist of 3 hoppers (±1g), 3 hoppers (±1g), and 3 hoppers (±1g). Each of the 3 materials is distributed across 3 hoppers, maintaining a control accuracy within ±1g. The formula weighing accuracy is effectively controlled for optimal performance.

For counting 1 material, the 10-head linear weigher utilizes 1 hopper (±0). Each material is allocated to a single hopper and is precisely fed through a vibrating rotary feeder. The weight accuracy is not considered in this setup, focusing on high-precision counting.

Other linear weigher systems for mixing

Contact Kenwei

Our company is located in a region with convenient transportation and a strong economy, ensuring timely product delivery and fast service. Throughout our operations, we prioritize customer satisfaction and offer quick, responsive support. Have questions or concerns about our products? Leave us a message, and our team will get back to you promptly with efficient solutions.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei