Weighing and Counting/Counting system

Discover Kenwei’s advanced weighing and counting machine solutions. Enhance your productivity with reliable, precise counting systems and packing machines designed for accurate weighing and packaging in your production line.

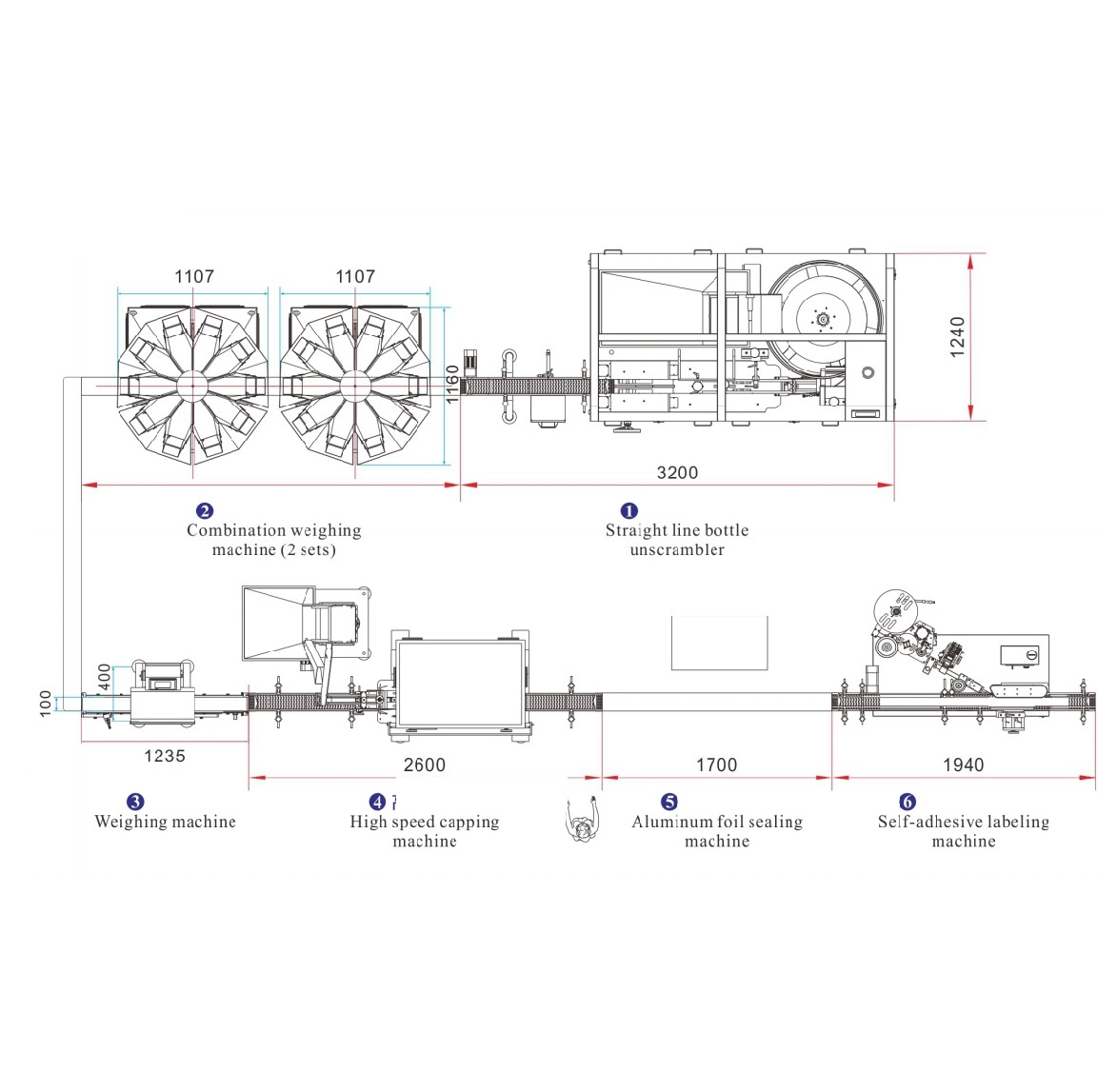

Weighing and counting/Counting line

Weighing and Counting/Counting line

Counting production lines include bottle or box arrangement, precise counting, box packaging, bottle packaging, labeling, and more.

Counting line: Includes self-made bags, weighing and counting of bags, printing, bagging, and output, among other functions.

Weighing and counting/Counting principles

When the hopper is placed in the weighing bucket of the multi-head weigher to measure the material in the barrel, the combination weigher calculates various combinations of different weighing hoppers. It then selects the optimal combination to achieve the target quantity after unloading.

Features

-

-

-

● High-precision, high-standard specialized load cells for accurate weighing performance.

-

● Factory parameter setting recovery function with multi-stage weight calibration for enhanced flexibility.

-

● Multiple parameter settings storage to meet various material requirements. The user-friendly menu display is easy to learn and use, with multi-language support, ensuring wide global application.

-

● Weighing material detection switch features a special double peak with a rotating rod on the top cone to prevent material buildup in the main vibration center. ● Each line's amplitude can be independently adjusted for more uniform feeding. Material shortages are automatically detected, ensuring stable weighing.

-

● Unique special program quantity with no channel chute to avoid material blockages.

-

● Material contact parts made from AISI316/AISI304 stainless steel, meeting stringent hygiene standards and easy to clean and maintain.

-

● High intelligence with fault self-test and advanced alarm control functions for better monitoring.

-

● Standard production processes with no special attention required, enhanced by multiple protection devices for operational safety.

-

-

Standard weighing and counting bottling system JW-B30

Application

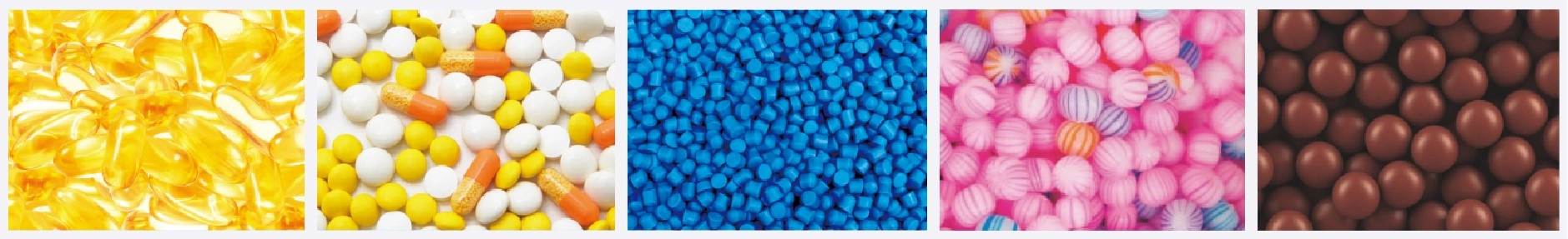

It is ideal for materials with consistent weight, uniform particles, minimal single bag weight error, and a larger weight error ratio between individual items. Examples include pills, capsules, chocolate beans, chewing gum, and more.

Features

-

-

-

● Ideal for products with strict weight and quantity requirements.

-

● Suitable for handling a small number of particles.

-

● Compatible with plastic bottles of various shapes and sizes.

-

● Offers high counting accuracy and efficiency for precise operations.

-

● Supports high-speed bottling and filling lines for fast production.

-

● Features stepless speed adjustment for reliable operation, smooth coordination, and stable material transport.

-

● Fully automated operation with intelligent control of both upper and lower processes, reducing the need for manual intervention and saving labor.

-

● Inverted bottle detection and waste removal function ensures no inverted bottles are reintroduced into the post-treatment process.

-

● Equipped with an unqualified product culling function (error detection and removal).

-

● Simple structure design for easy maintenance and operation.

-

● Cost-effective solution offering excellent value at a reasonable price.

-

-

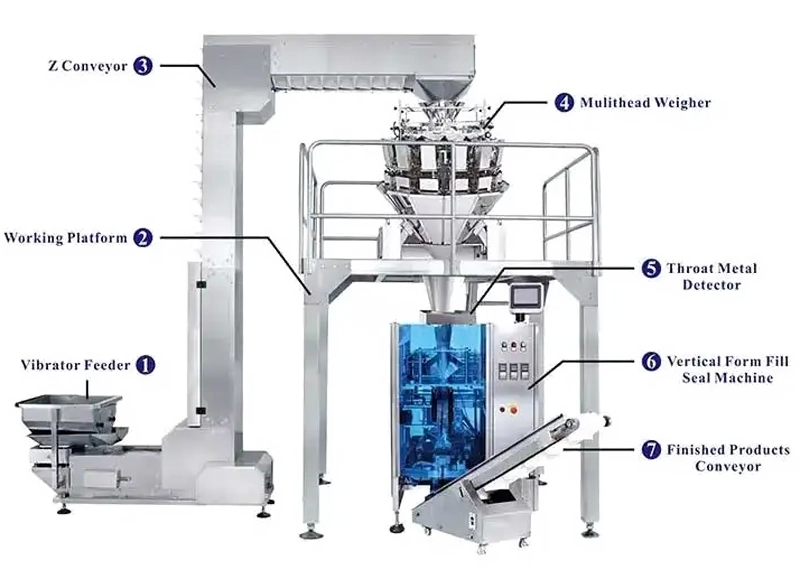

Standard weighing and counting bagging

system JW-B31

The system includes a vibration feeder, platform, Z-type conveyor, counting weigher, metal detector for dropped items, vertical packaging machine, and finished product conveyor.

Application

It is very suitable for materials with consistent size, minimal single bag weight error and individual weight differences, such as pills, capsules, chocolate beans, chewing gum, hardware plastic parts, electronic components, etc.

Features

-

-

● Ideal for products with precise weight and quantity requirements.

-

● Suitable for handling small quantities of particles.

-

● Compatible with plastic bottles of various shapes and sizes.

-

● Highly versatile: packaging machine accommodates bags of different sizes.

-

● Offers high counting accuracy and efficiency for optimal performance.

-

● Fully automated operation with intelligent control of both upper and lower processes, reducing the need for manual intervention and saving labor.

-

● Equipped with a culling function for unqualified products (error detection and removal).

-

● Simple structure design for easy maintenance and operation.

-

● Cost-effective solutions with reasonable pricing.

-

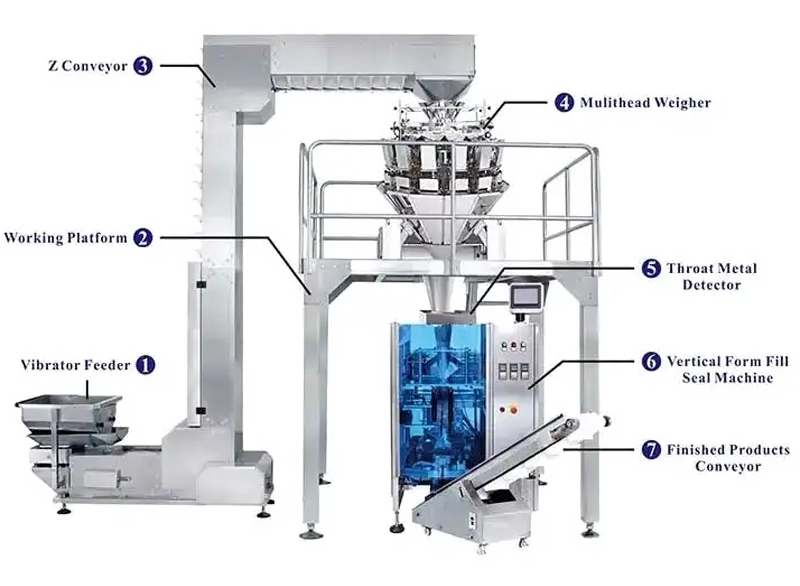

Weighing and counting system JW-B32

Application

It is ideal for materials with consistent size, minimal weight error per bag, as well as materials with significant weight variations per item or bag.

Features

-

-

-

-

● Ideal for products with strict weight and quantity requirements.

-

● Suitable for handling small quantities of particles.

-

● Compatible with plastic bottles of various shapes and sizes.

-

● Offers high counting accuracy and exceptional efficiency.

-

● Designed for high-speed bottling and filling lines.

-

● Features stepless speed adjustments for reliable operation, coordinated actions, and stable transportation.

-

● Fully automated operation with intelligent control of both upper and lower processes, reducing the need for manual intervention and saving labor.

-

● Equipped with an inverted bottle detection and waste removal function to ensure no inverted bottles are returned to the post-treatment process.

-

-

-

Contact Kenwei

Our company is located in a region with convenient transportation and a strong economy, ensuring timely product delivery and fast service. Throughout our operations, we prioritize customer satisfaction and offer quick, responsive support. Have questions or concerns about our products? Leave us a message, and our team will get back to you promptly with efficient solutions.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei