Semi Automatic Weighing System

Discover Kenwei’s Semi-Automatic Weighing System—ideal for precise, efficient weighing in food and packaging industries. Explore semi-automatic weighing machine solutions from a leader in checkweighers and multihead packing machinery.

Semi Automatic Weighing System

Series Modle

● Semi-auto weighing and packaging system (one output)

Packaging speed:

15-20 bags per minute (low speed; multi-head weigher operating under low-load conditions).

● Semi-auto weighing and packaging system (two outputs)

Packaging speed:

30-40 bags per minute (requires two operators to collect the product, with the multi-head weigher operating under normal load conditions).

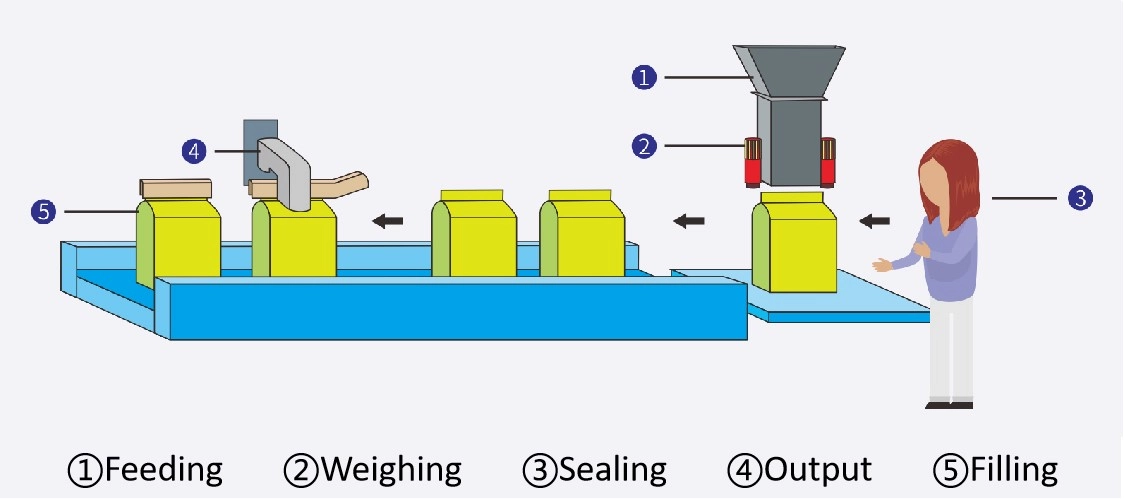

Manual Packing System Process Flow

Characteristic

-

● Fully automatic process from feeding to weighing for seamless operation.

-

● Versatile and efficient, suitable for a wide range of products with high accuracy.

-

● Space-saving design that reduces input costs.

-

● Compatible with various bag types that other packaging machines may not handle.

-

● Cost-effective with an excellent price-to-performance ratio.

Optional Equipment

● Check Weigher:Reject unqualified products, it can sort the product and make statistics (if alreadyequipped with other weight detection equipment then no need use this machine)

● Horizontal Metal Detector:It is used to detect the metal which mixed during the production process.It is suitable to use after finishing packaging (ifalready equipped with othermetal detector then no need use this machine).

● Throat MetalDetector:It is used to detect the metal which mixed during the production process.It is suitable to use before packaging. It is installed between weigher andpackaging machine, space saving (if already equipped with other metaldetector then no need use this machine).

● MetalDetector Combined With Check Weigher:It is used to detect the metal and check weight, combined the check weigherwith metal detector, save cost and less commissioning and maintenance time.

● Finished Product Conveyor:To convey the product up to next process line.

Two outlet semi auto weighing and packing system JW-B16

Application

This system is ideal for weighing a variety of products, including granules, sliced items, rolled goods, and irregularly shaped products such as candies, seeds, jelly, French fries, coffee beans, peanuts, puffed food, biscuits, chocolates, pet food, small hardware, and more.

Characteristic

-

● Fully automated process, including feeding, weighing, and finished product output.

-

● Wide application range, suitable for various materials with high precision and efficiency in weighing.

-

● Space-saving and cost-effective design.

-

● Affordable with a high cost-performance ratio, ideal for packaging a variety of bag types that traditional packaging machines cannot handle.

Two-outlet semi-auto weighing and packing system (with inclined conveyor) JW-B17

Application

It is ideal for weighing a variety of products, including granules, slices, rolled items, and irregularly shaped goods, such as candy, seeds, jelly, French fries, coffee beans, peanuts, puffed snacks, biscuits, chocolate, pet food, small hardware, and more.

Characteristic

-

● Fully automated process, seamlessly handling everything from feeding and weighing to finished product output.

-

● Versatile and suitable for a wide range of materials, offering high weighing accuracy and efficiency.

-

● Space-saving design that helps reduce input costs.

-

● Cost-effective, with a high price-to-performance ratio, ideal for various bag types that cannot be processed by standard packaging machines.

● Chain plate inclined conveyor: designed for conveying larger-sized products.

● Belt type inclined conveyor: ideal for transporting granules, powders, and similar materials.

Two outlet semi auto weighing and packing system (with vacuum feeding machine) JW-B18

Application

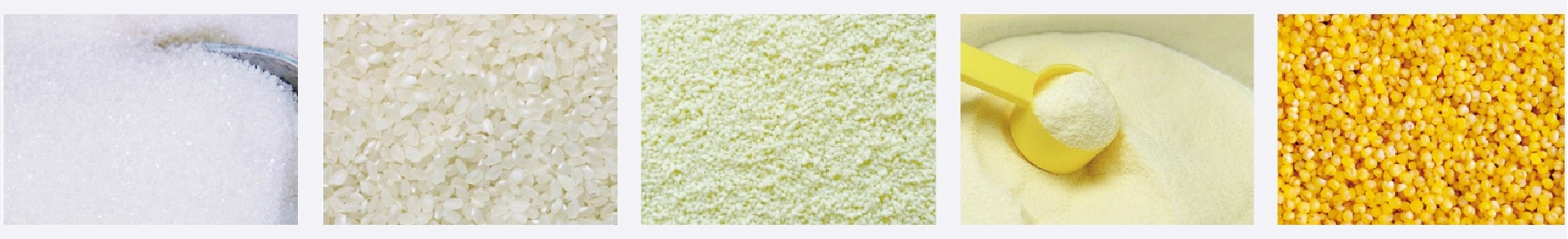

It is ideal for weighing regular-shaped granules, powders, or rolled products, including sugars, salt, seeds, rice, sesame, glutamic acid, milk powder, coffee, and seasoning powders.

Characteristic:

-

● Fully automated process, from feeding and weighing to finished product output.

-

● Versatile and suitable for a wide range of materials, offering high precision and efficiency in weighing.

-

● Space-saving design and cost-effective input.

-

● Ideal for weighing powders, rolled products, or regular-shaped granules.

-

● Affordable pricing with a high cost-performance ratio, perfect for various bag types that cannot be processed by conventional packaging machines.

Two outlets semi-auto weighing and packing system (with vacuum feeding machine and linear weigher) JW-B19

Application

It is ideal for weighing regular-shaped granules, powders, or rolled products, including sugars, salt, seeds, rice, sesame, glutamic acid, milk powder, coffee, and seasoning powders.

Characteristic

● Fully automated process from feeding and weighing to finished product output.

● Versatile and suitable for various materials, ensuring high precision and efficiency in weighing.

● Space-saving design and cost-effective, reducing input costs.

● Ideal for weighing powders, rolled products, and regularly shaped granules.

● Affordable with a high cost-performance ratio, compatible with all types of bags that traditional packaging machines cannot handle.

Two outlets semi-auto weighing and packaging system (with single bucket conveyor and linear weigher) JW-B20

Application

It is ideal for weighing powders, rolls, and uniformly shaped granules, including sugar, salt, seeds, rice, sesame, monosodium glutamate, milk powder, coffee, seasoning powder, and more.

Characteristic

● Fully automatic process, from feeding and weighing to finished product output.

● Versatile and efficient, suitable for a wide range of materials with high precision and reliability.

● Space-saving design that reduces input costs.

● Ideal for weighing powders, rolls, or uniformly shaped granules.

● Affordable, cost-effective solution, compatible with various bag types that traditional packaging machines cannot handle.

Contact Kenwei

Our company is located in a region with convenient transportation and a strong economy, ensuring timely product delivery and fast service. Throughout our operations, we prioritize customer satisfaction and offer quick, responsive support. Have questions or concerns about our products? Leave us a message, and our team will get back to you promptly with efficient solutions.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei