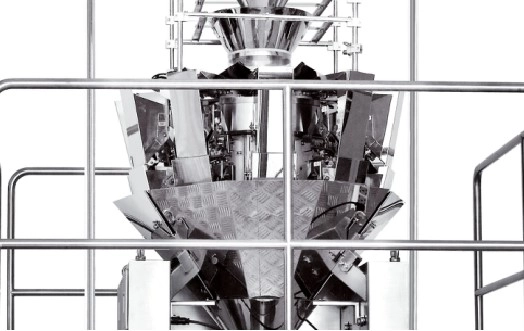

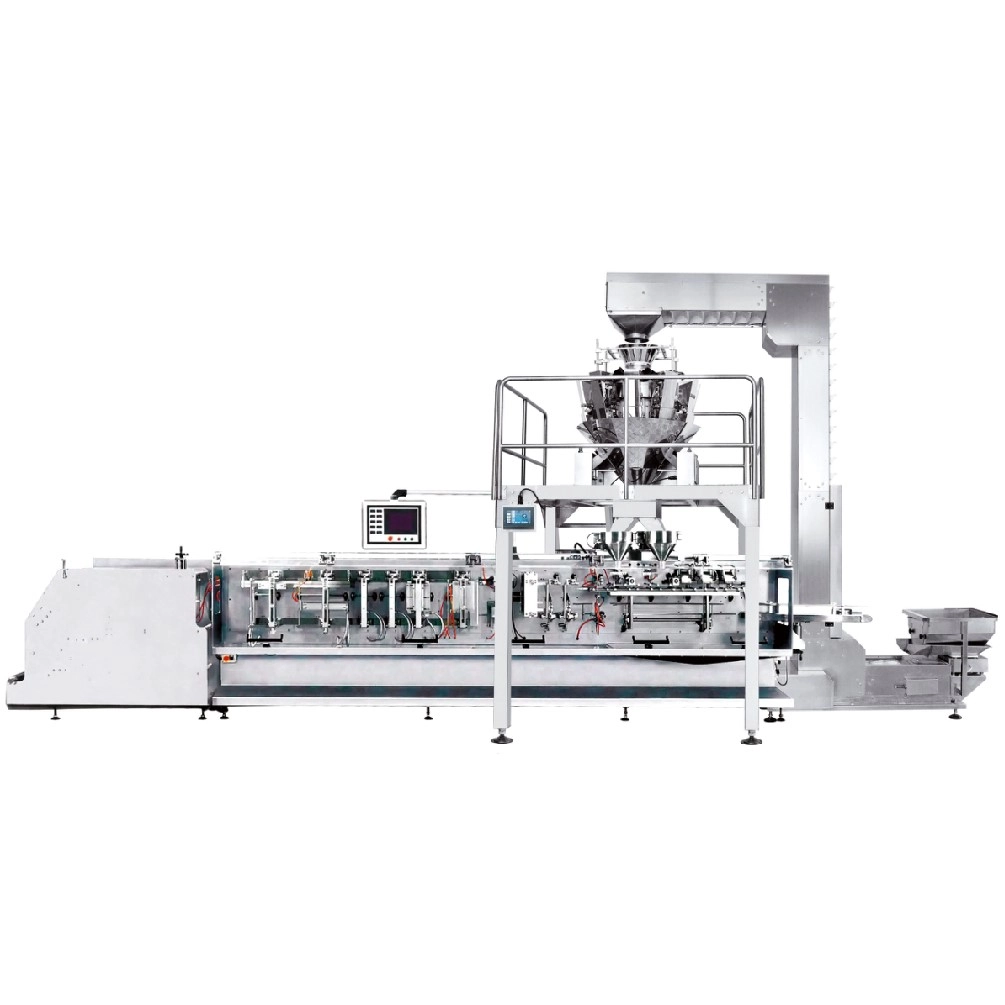

Manual Vacuum Conveyor Multi Heads Weigher Packaging Machine for granule food JW-B18

The Kenwei JW-B18 Two-Outlet Semi-Auto Weighing and Packing System with Vacuum Feeding is ideal for weighing powders and regular-shaped granules such as coffee, sugar, rice, salt, and milk powder. It offers fully automatic feeding, weighing, and bag filling with high accuracy and speed. Compact and cost-effective, it supports bag types unsuitable for standard machines, making it perfect for space-limited and budget-conscious operations.

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | Supply Ability | 500 sets/year |

Feature

-

-

● Fully automatic finishing whole process of feeding, weighing, filling bag, date printing,output.

● High accuracy and high speed.

● Save space and input cost.

● Suitable for weighing powder and roll or regular shape granule.

● cheapness, high price ratio, Suitable for kinds of bag type which cann’t made by packaging machine.

-

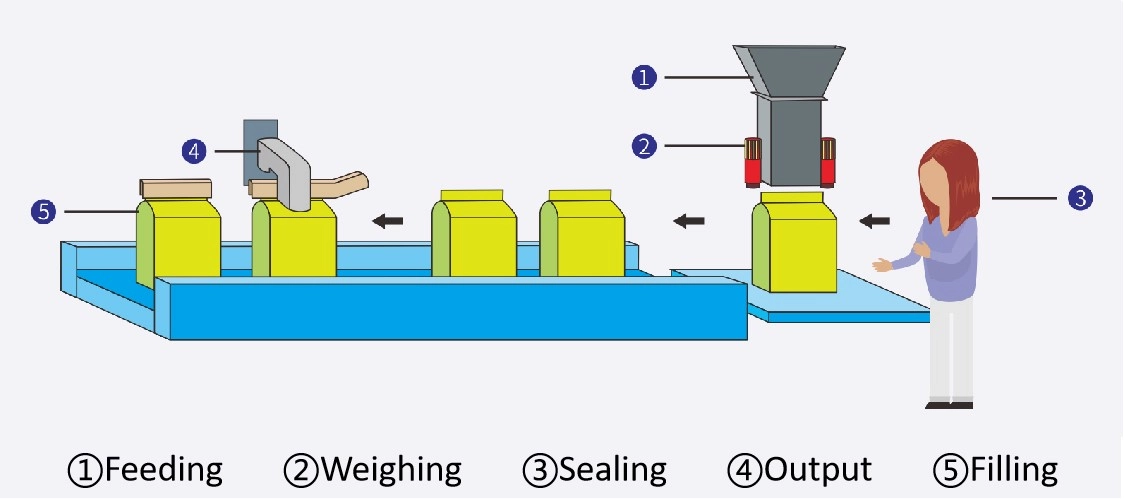

Manual Packing System Process Flow

- The Manual Packing System follows a streamlined process: feeding, weighing, filling, sealing, and output. This setup ensures basic packaging efficiency while allowing flexibility and control, ideal for small-scale or customized production operations.

Series Models

Application

|

It is suitable for weighing powder and roll or regular shape granule, such as sugar, salt, seed, rice, sesame, glutamate, milk powder, coffee and season powder,etc.

|

Optional Equipment

Check weigher

Eliminates products that don’t meet weight standards, sorts them, and generates statistical data. (if already equipped with other weight detection equipment then no need use this machine)

Horizontal Metal Detector

Used to detect any metal contamination that may have occurred during the production process. It is ideally placed after packaging is complete.(if already equipped with other weight detection equipment then no need use this machine)

Metal Detector with Check weigher

Combines metal detection and weight checking in one unit, reducing costs and minimizing commissioning and maintenance time.

Z Type Finished Product Conveyor

Raise the product height and transport it to the next process smoothly.

Throat Metal Detector

Detects metal contamination before packaging, installed between the weigher and packaging machine for space efficiency.(if already equipped with other weight detection equipment then no need use this machine)

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About Cooperation Process

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

Economic Premade Pouch Weighing And Packing Machine System JW-B15

Precision Food Packaging Machine Using Single Head Bulk Linear Weigher Packaging System JW-B22

Z Type Bucket Conveyor for Food Conveying and Handling Applications

Precision Linear Weigher for Weighing Powder & Small Granules

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei