Precision Food Packaging Machine Using Single Head Bulk Linear Weigher Packaging System JW-B22

The Kenwei JW-B22 Precision Food Packaging Machine with Single Head Bulk Linear Weigher is designed for heavy-duty weighing up to 50kg. It automates feeding, weighing, bag sewing, and output for maximum efficiency. Ideal for grains like corn, rice, soybeans, barley, and wheat, it ensures high accuracy and reliability for the food, chemical, and light industries, making it the top choice for bulk grain packaging.

| Supply Ability | 1000sets/year | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 30days |

| Start Port | Zhongshan port | ||

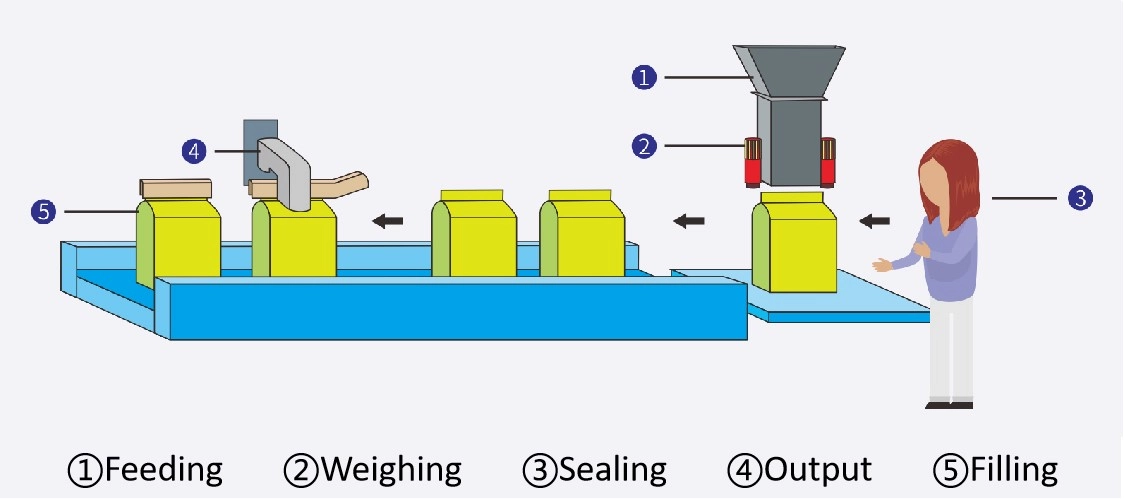

Big Weight Packing Process Flow

- The Big Weight Packing System follows a streamlined process: feeding, weighing, filling, sealing, and output. This setup ensures basic packaging efficiency while allowing flexibility and control, ideal for small-scale or customized production operations.

Feature

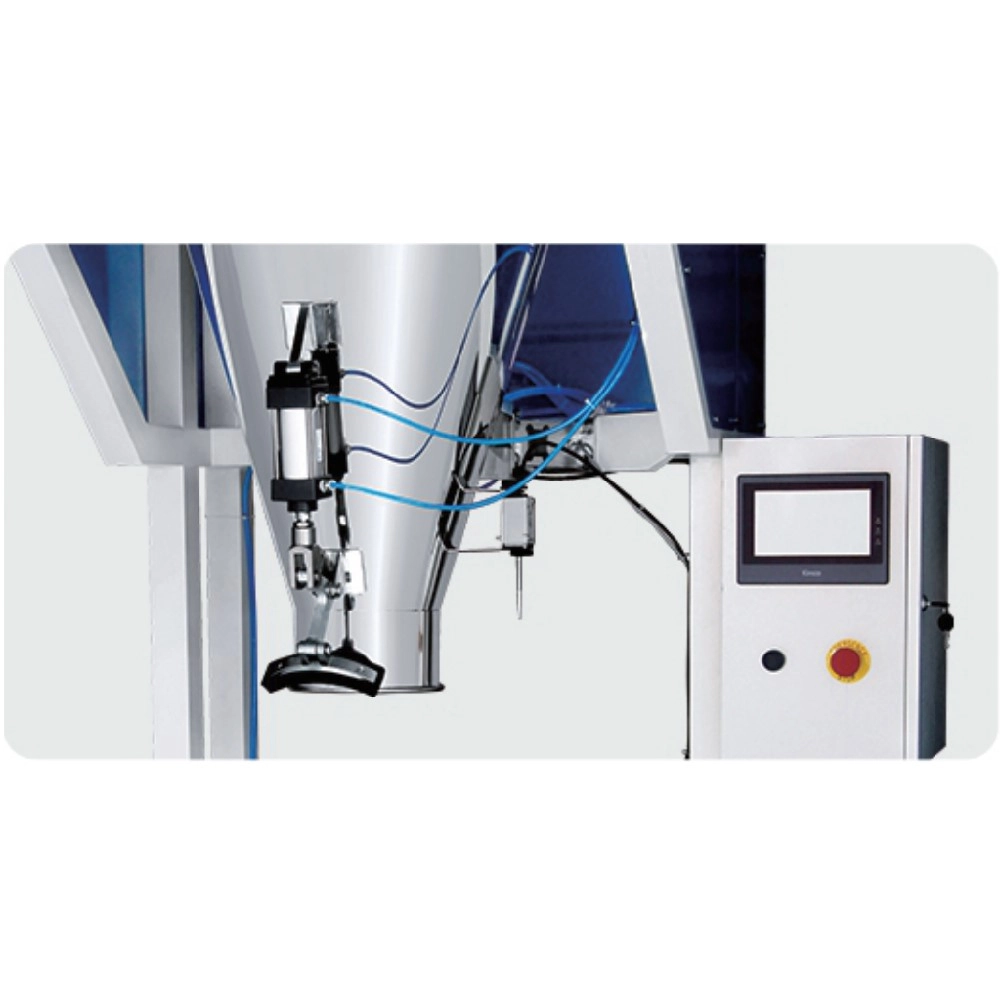

System including: a bulk weigher, horizontal belt conveyor, sack closer, inclined conveyor, and vibratory feeder.

-

-

● Supports a weighing range of up to 50 kg.

-

● Fully automated process, including feeding, weighing, bag sewing, and final product output.

-

● Delivers exceptional weighing accuracy and high operational efficiency.

-

● The ideal solution for grain packaging in the food, agriculture, and related industries.

-

Application

It is suitable for weighing corn, soybeans, rice, barley, wheat, forage and other small granules in food industry, light industry, chemical industry.

Packing Puch

The weighing and packaging system is compatible with various bag types, as illustrated in the figure on the right.

Optional Equipment

Check Weigher

Used for check weight, and remove the unqualified products, classification and statistics of products.

Horizontal Metal Detector

Used for detect both magnetic and nonmagnetic metals which mixed in the products in the production process, suitable for detect after packaging.

Dropped Metal Detector

Used for detect both magnetic and nonmagnetic metals which mixed in the products in the production process, suitable for detect before packaging, and fixed between the bottom of weigher and the top of VFFS feeding funnel, save space, but increase the hight of system.

Combined Check Weigher And Metal Detector

Used for check the weight of products and detect the metal which mixed in the products, remove the unqualified products. It Combines check weigher and metal detector, save cost and the time of debugging and maintenance.

Z Conveyor

Applicable to small space, delivery value is not large, and need vertical convey the product to the next process.

Inclined Conveyor

Chain plate type inclined conveyor:

Applicable to convey large amount product, high speed, need large space to set up.( can't convey small granules and powder).

Belt type inclined conveyor:

Applicable to convey large amount product, high speed, need large space to set up.

Vacuum Feeding Machine

Used for convey small granules or powder, save space.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About products customization

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

Automatic Weighing and Canning Filling System for Efficient Packaging Solutions JW-B24

Z Type Bucket Conveyor for Food Conveying and Handling Applications

Double inlet rotary packaging and weighing system JW-B9

Double Feeding Vertical Snack Packing Machine for Factories with Height Restrictions JW-B3

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei