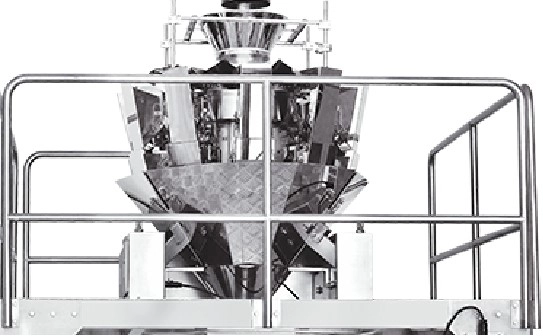

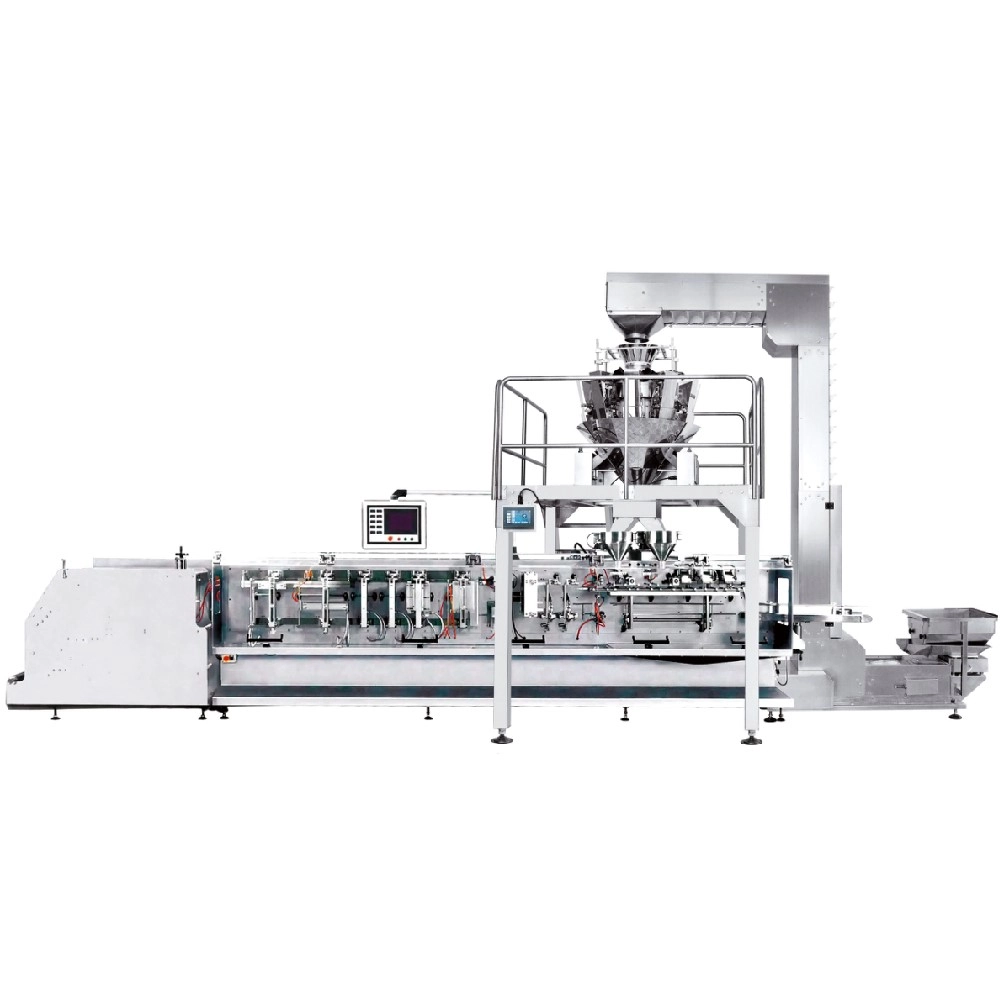

Two Outlet Semi Auto Sugar Weighing and Packaging Machine JW-B16

The Kenwei JW-B16 Two Outlet Semi-Auto Sugar Weighing and Packaging Machine delivers high-precision, automated weighing for granules, slices, and irregular products like candy, coffee beans, and pet food. With a compact, cost-effective design and excellent price-performance ratio, it supports unique bag types and boosts efficiency. Optional add-ons like check weighers, metal detectors, and conveyors ensure quality control and seamless integration. Ideal for food and hardware industries.

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | Supply Ability | 500 sets/year |

Feature

-

● Experience seamless automation from feeding to weighing and delivering your perfectly packaged products with unmatched precision.

● Enjoy versatility across various materials, assuring high weighing accuracy and unmatched efficiency.

● Compact, space-saving design that reduces input costs significantly.

● Cost-effective solution boasting a remarkable price-to-performance ratio, perfect for handling unique bag types beyond the capabilities of conventional machines.

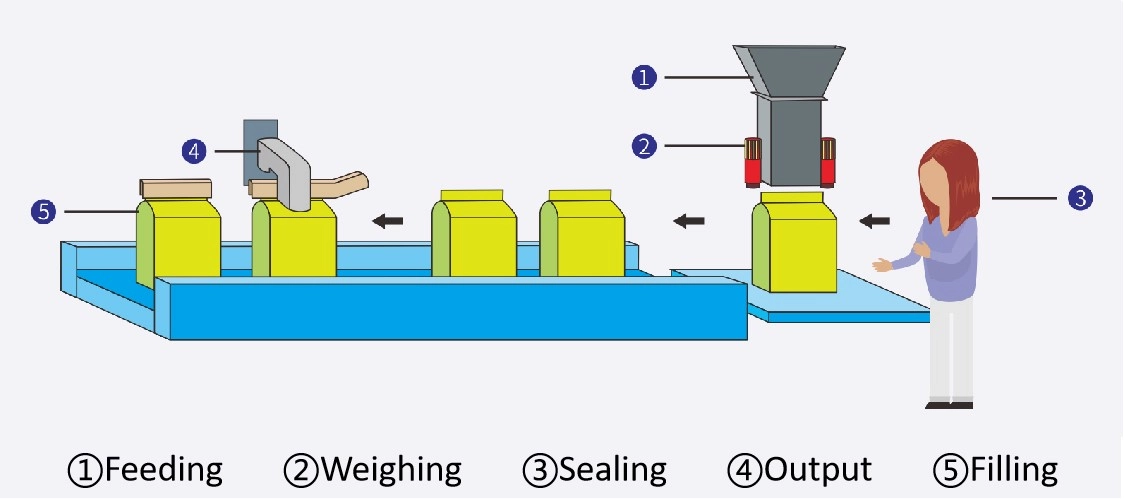

Manual Packing System Process Flow

- The Manual Packing System follows a streamlined process: feeding, weighing, filling, sealing, and output. This setup ensures basic packaging efficiency while allowing flexibility and control, ideal for small-scale or customized production operations.

Series Models

Application

This machine is ideally suited for weighing an array of products including granules, slices, rolls, and irregular items-candy, seeds, jelly, fries, coffee beans, peanuts, puffed snacks, biscuits, chocolates, nets, pet food, small hardware, and more.

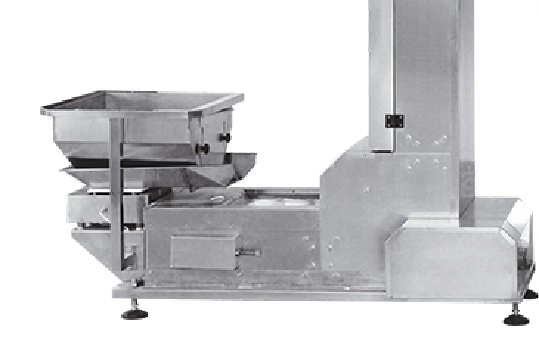

Optional Equipment

Check weigher

Eliminates products that don’t meet weight standards, sorts them, and generates statistical data. (if already equipped with other weight detection equipment then no need use this machine)

Horizontal Metal Detector

Used to detect any metal contamination that may have occurred during the production process. It is ideally placed after packaging is complete.(if already equipped with other weight detection equipment then no need use this machine)

Metal Detector with Check weigher

Combines metal detection and weight checking in one unit, reducing costs and minimizing commissioning and maintenance time.

Z Type Finished Product Conveyor

Raise the product height and transport it to the next process smoothly.

Throat Metal Detector

Detects metal contamination before packaging, installed between the weigher and packaging machine for space efficiency.(if already equipped with other weight detection equipment then no need use this machine)

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About Solution suggestions

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

Precision Food Packaging Machine Using Single Head Bulk Linear Weigher Packaging System JW-B22

Two-outlet semi-auto weighing and packing system with inclined conveyor JW-B17

Weighing and packing systems with double inlet pre-made bag packing machines JW-B14

Economic vertical form fill seal packing machine(VFFS)

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei