Economic vertical form fill seal packing machine(VFFS)

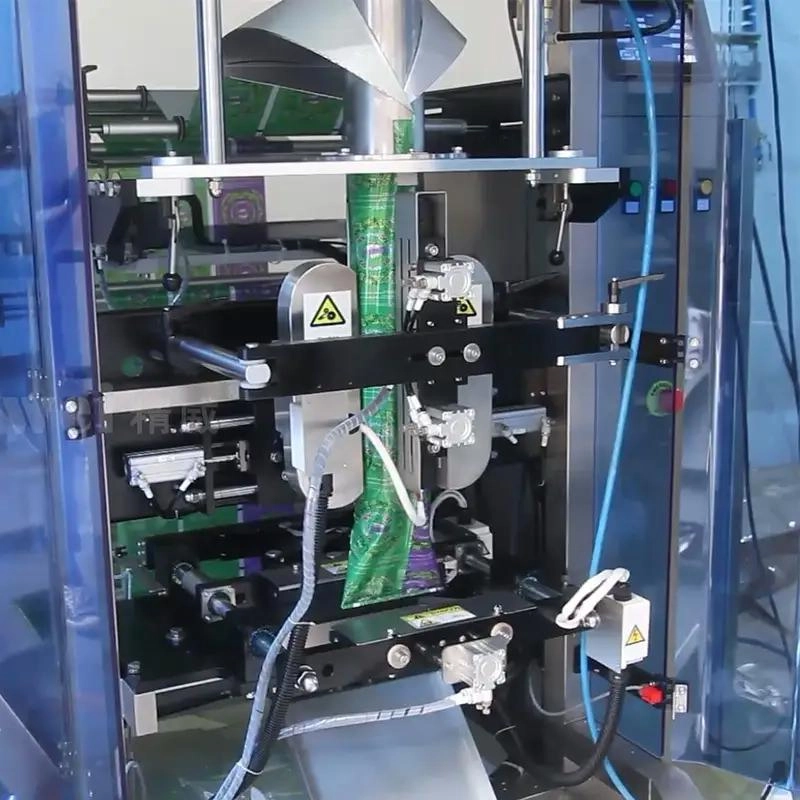

The economical vertical form fill seal (VFFS) packaging machine offers a variety of models designed with a sturdy 304 stainless steel frame. It is equipped with safety door protection and supports multiple bag types, including pillow bags, angle belt bags, printed bags, and triangle bags. This versatile machine is ideal for packaging a wide range of materials, such as snacks, frozen foods, coffee beans, oats, sugar, salt, rice, small hardware components, and more. Affordable and cost-effective, it provides reliable performance and efficiency for diverse packaging needs.

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | Supply Ability | 5000 sets/year |

| Gas Pression | 0.6~0.8Mbra | ||

Feature

-

● Automatic Alarm and Warning: Integrated PLC system for real-time alerts and notifications.

-

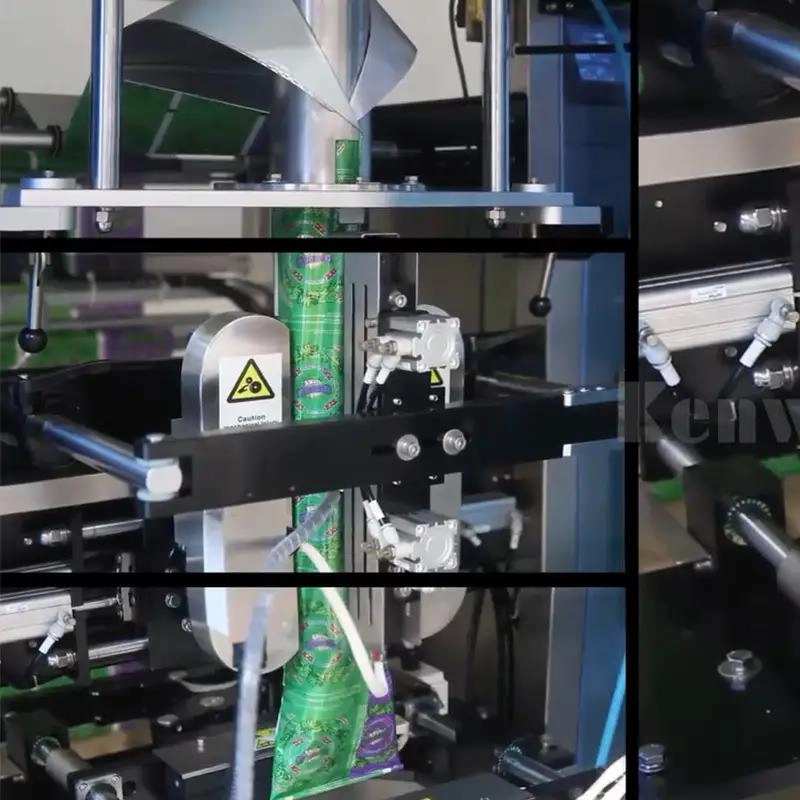

● Bag Making: Automatic bag formation with a vertical layout; features a concave-convex point flanging collar for secure sealing.

-

● Horizontal Sealing: Servo motor-driven horizontal seal with dynamic sealing bar and continuation heating. Constant temperature control ensures stable sealing, while the system includes cooling and blowing functions for precise sealing. It also features motor swing angle protection and automatic shutdown during material clamping.

-

● Vertical Sealing: Vertical seal with cylinder-driven dynamic clamping. Standard vertical sealing is clamp-type, with heat continuation for consistent temperature control.

-

● Film Pulling: Dual vacuum synchronous belt-driven film pulling system, powered by a motor with cone gear drive. Includes a manual transfer switch for easy adjustments.

-

● Film Releasing: Motor-driven rubber roller for film release, with three-speed control. Features include coding adjustment, eye mark tracking, deviation correction, anti-shake transport, no film alarm, and film detector with pneumatic pressing function.

-

● Frame: Sturdy assembly frame with blue perspective plexiglass doors, electric tank fission rotating human-machine interface. Built-in auto-stop protection when the door is opened for added safety.

Technical Specification

| Model | JW-E3220 | JW-E4230 | JW-E5235 | JW-E6240 | JW-E7245 | JW-E8350 |

| Film width(mm) | 140~320 | 160~420 | 180~520 | 180~620 | 180~720 | 180~830 |

| Bag size(L*W)(mm) | 60~200*60~150 | 60~300*70~200 | 60~350mm*80~250 | 80~400*80~300 | 90~450*70~350 | 90~500*60~400 |

| Packing speed | 15~70bags/min | 15~60bags/min | 15~60bags/min | 15~60bags/min | 0~70bags/min | 5~50bags/min |

| Power requirement | 2.5KW/220V/50/60HZ | 3.4KW/220V/50/60HZ | 3.4KW/220V/50/60HZ | 3.6KW/220V/50/60HZ | 5.5KW/220V/50/60HZ | 5KW/220V/50/60HZ |

| Gas pressure(Mbra) | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

| Gas consumption | 0.5m³/min | 0.6m³/min | 0.7m³/min | 0.8m³/min | 0.4m³/min | 1.2m³/min |

| Machine size(L*W*H)(mm) | 1158*930*1213 | 1465*1040*1470 | 1540*1160*1600 | 1640*1226*1709 | 1748*1344*1955 | 1848*1544*2155 |

| Machine weight(Kg) | 350 | 400 | 450 | 550 | 680 | 800 |

Optional device

| Gusset device | Nitrogen charging device |

| Chain bag |

Vibrating device |

| Punching device | Sealing device |

| Exhaust/Inflatable devices | Easy tear device |

| PE film sealing | Bag support device |

| Anti-Static electricity | Evacuating device |

| Horizontal seal cooling blowing device | Film rectify deviation adjust device |

| Automatic feeding device |

|

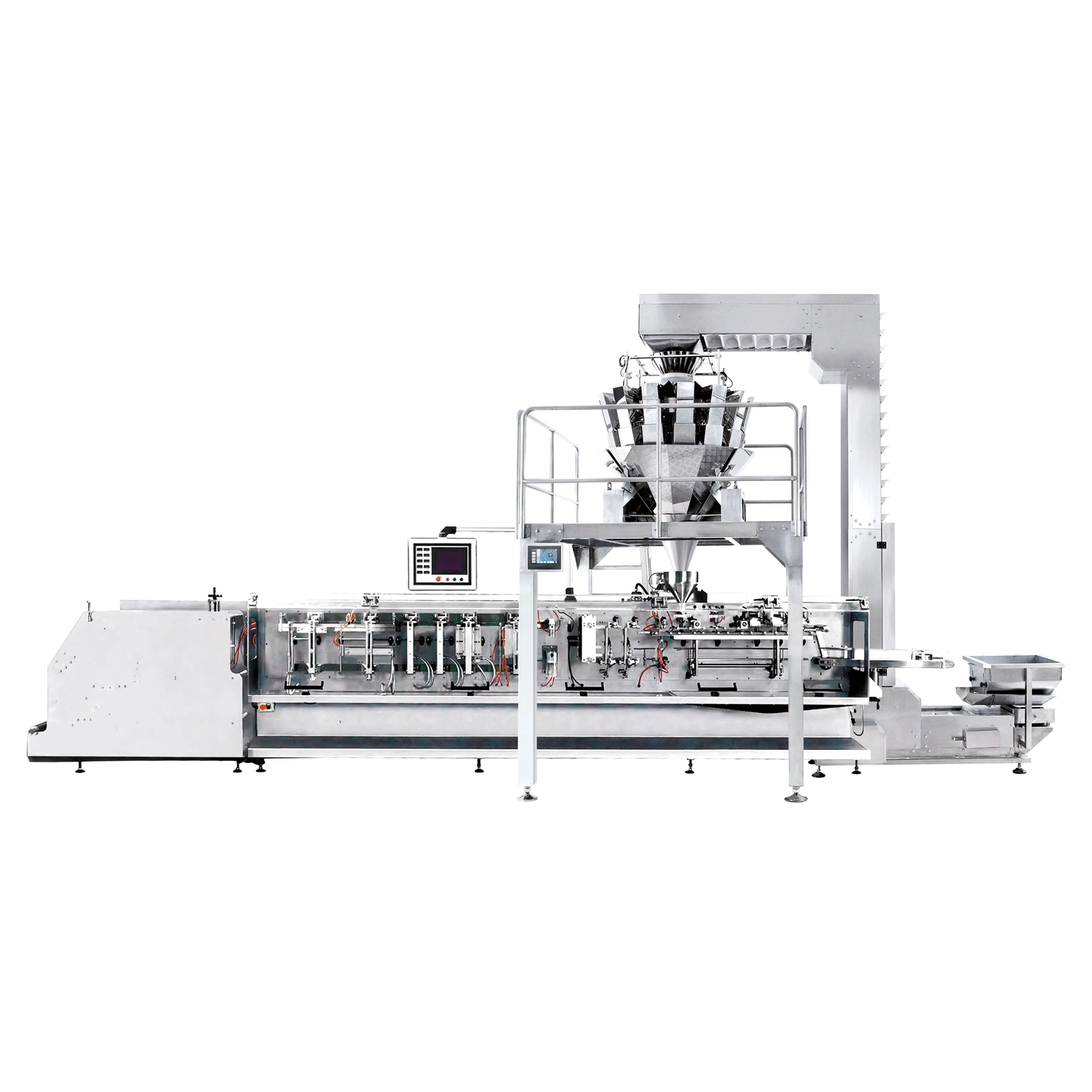

Common related equipment

| Multihead weigher/Liner weigher | Cup measuring machine |

| Auger filler | Liquid pump |

Application

-

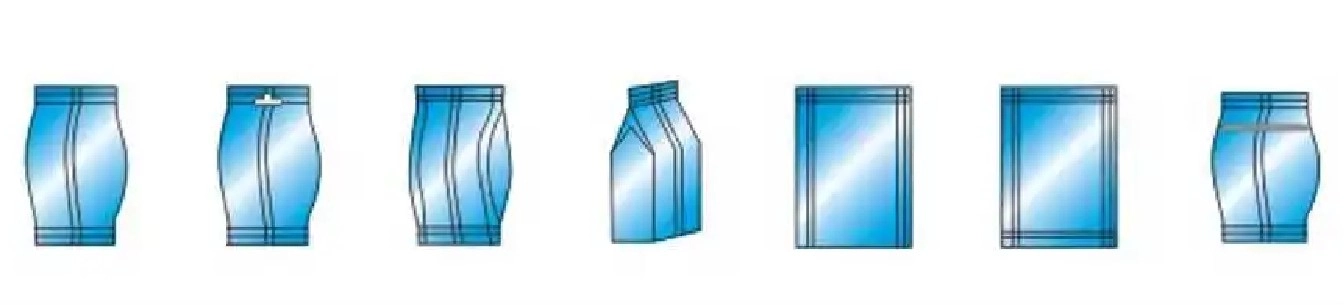

● Compatible Bag Types: Pillow bags, Gusset bags, and Seal-type bags for versatile packaging options.

-

● Suitable Film Materials: Works with various laminated films, single-layer PE films, with a film thickness range of 0.04 mm to 0.15 mm.

Applicable Packing Materials: Ideal for packaging a wide range of products including recreational snacks, frozen foods, milk powder, coffee, oatmeal, granulated sugar, salt, puffed snacks, rice, herbs, tea, small hardware, and more.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

About Product choice

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

Two Outlet Semi Auto Sugar Weighing and Packaging Machine JW-B16

Automatic Premade Pouch Weighing and Filling Machine for Snacks Pet Food JW-B13

Parallel Robot Pick and Place System for Automated Packaging and Production Lines

Mini Combined Weighing and Packing Machine with Multihead Weigher for Tea Powder, Coffee Beans, and More

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei