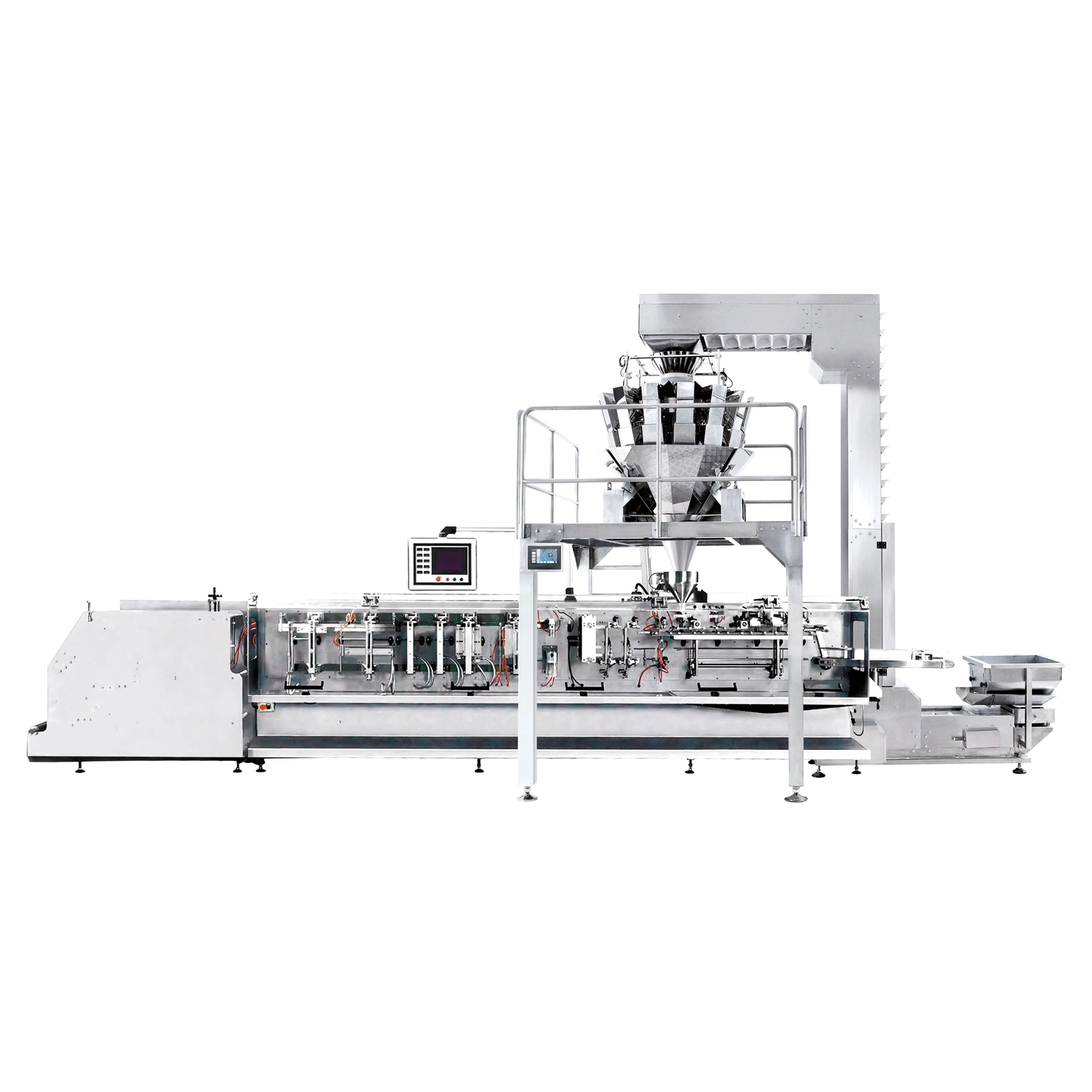

Parallel Robot Pick and Place System for Automated Packaging and Production Lines

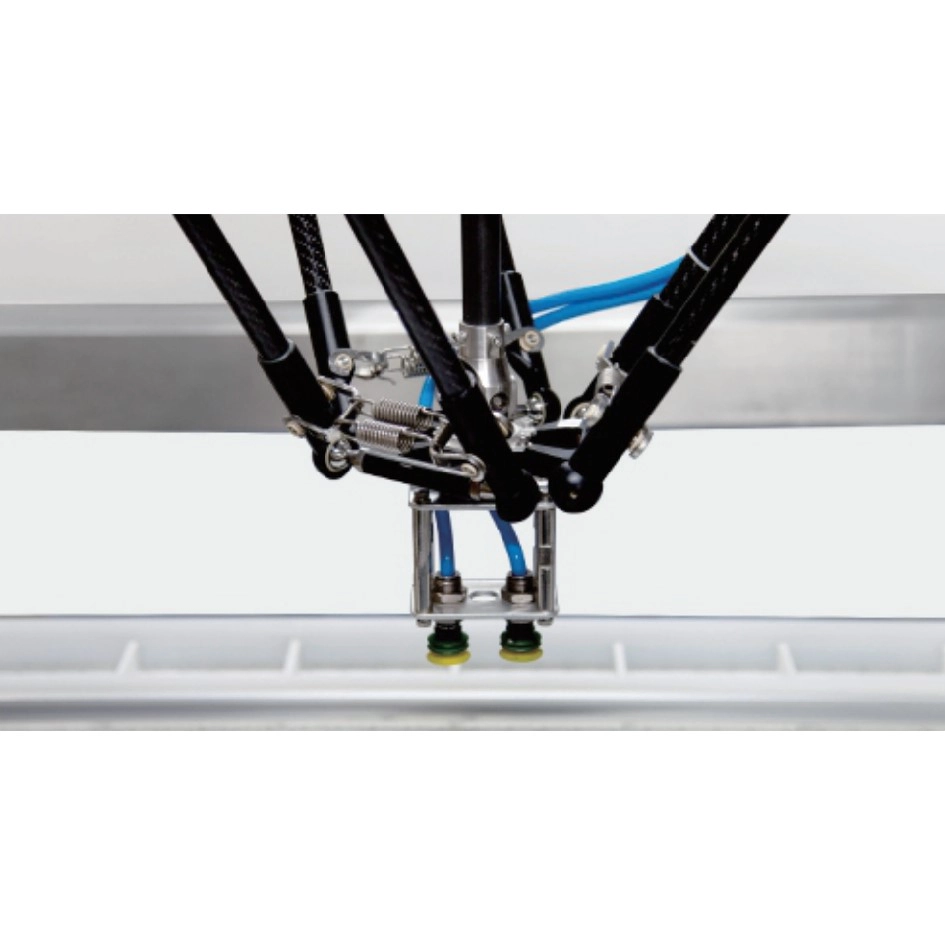

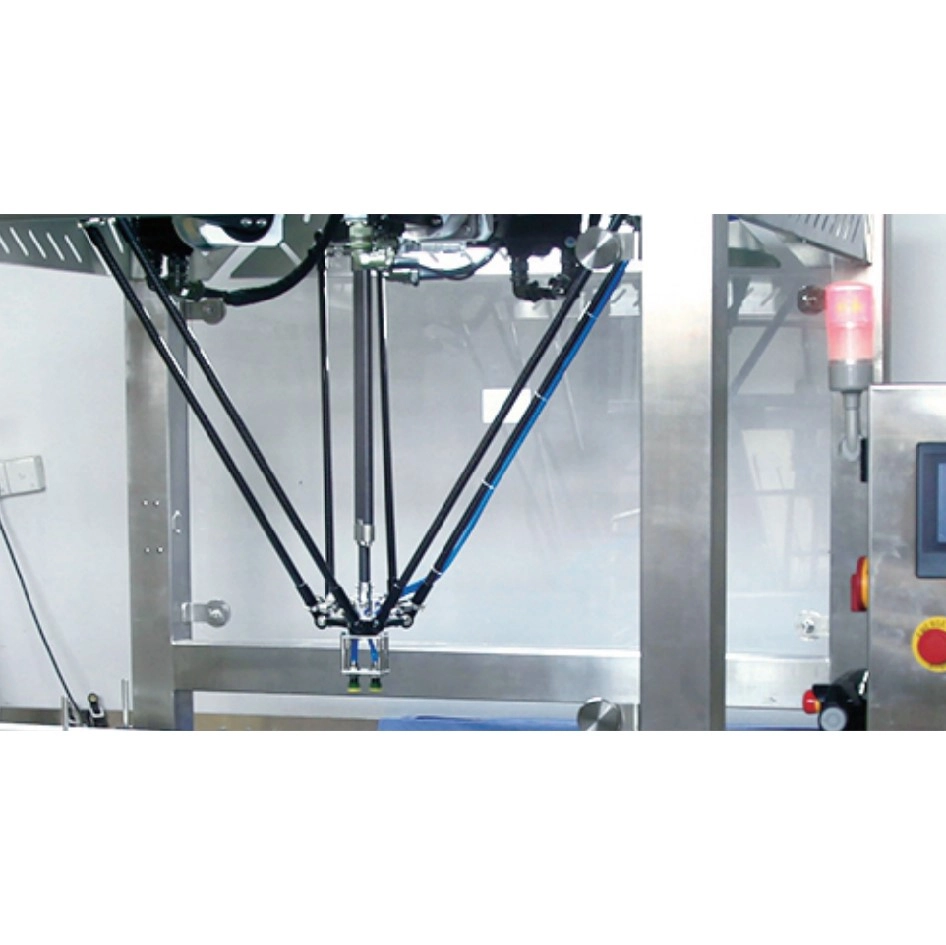

The parallel manipulator features a 4-axis linkage structure and a high-precision servo control system, ensuring accurate and reliable operation. It can be integrated with a vision system or onboard conveyor, supporting customized conveying solutions with flexible configuration options. This system is ideal for automated handling of various materials across industries such as food, pharmaceuticals, condiments, plastics, handicrafts, electronics, and more.

| Repeat Accuracy | ±0.1mm | Max Load | 150P/M |

| Structure Type | DELTA(four-axis parallel) | Supply Ability | 5000sets/year |

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | ||

Feature

● Compatible with front-end checkweighers, metal detectors, X-ray inspection systems, and other automated packaging line equipment. Offers strong versatility, wide applicability, high precision, and excellent stability.

● Capable of high-speed sorting with optional vision system integration for enhanced positioning accuracy and efficient automatic sorting, palletizing, and intelligent operations.

● User-friendly touch screen HMI supports multi-coordinate debugging, jog control, and parameter configuration. Offers teaching mode for linear, arc, and 3D trajectory programming.

● Supports multi-station scheduling.

● Features teaching pendant for easy programming, a comprehensive instruction set, and support for secondary development to meet diverse application needs.

● Equipped with overload auto shutdown protection for safe operation.

Mechanical Character

Technical Specification

| Model |

JW-D1100 |

| Identify Code |

D1100-1-1 |

| Repeat Accuracy | ±0.1mm |

| Max Speed |

150P/M |

| Working Range |

φ1100mm |

| Max Load |

3000g |

| Structure Type | DELTA(four-axis parallel) |

| Power Requirement | 220V/4000W/ 50/60Hz /20A |

| Packing Dimension(mm) | 1200(L)X1100(W)X610(H) |

| Gross Weight | 110kg |

|

*: Depends on product shape, product density, target weight etc. |

|

Application

Suitable for sorting and conveying various materials across multiple industries, including food, pharmaceuticals, spices, plastics, handicrafts, electronics, and more. Designed to meet the diverse handling needs of modern automated production environments.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About Solution suggestions

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

Economic vertical form fill seal packing machine(VFFS)

Two Outlet Semi Auto Sugar Weighing and Packaging Machine JW-B16

Automatic Dual-Axis Industrial Robotic Arm for Packaging and Production Automation

Automatic Premade Pouch Weighing and Filling Machine for Snacks Pet Food JW-B13

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei