Automatic Dual-Axis Industrial Robotic Arm for Packaging and Production Automation

This product is a standard two-axis parallel manipulator with simple structure, beautiful appearance, convenient installation and maintenance, small space occupation and high reliability. It adopts modular design, easy debugging, long life, low maintenance cost, and supports multi-angle visual control. It has the function of grabbing and placing, equipped with automatic positioning of the visual system, and realizes automatic stacking and sorting.

| Working Range | 1000X360mm | Max Load | 3000g |

| Structure Type | Two Axes In Parallel | Supply Ability | 3000sets/year |

| Repeat Accuracy | ±0.2mm | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | ||

Feature

● This standard 2-axis parallel robotic arm features a compact design, easy installation and maintenance, reliable performance, and an aesthetically pleasing appearance.

● Engineered with a modular structure for quick setup and debugging, it offers a long service life, low maintenance costs, and supports multi-angle visual monitoring.

● Equipped with a vision-guided system, it enables precise grabbing, placement, palletizing, and sorting tasks based on real-time product positioning.

Mechanical Character

Technical Specification

| Model |

JW-D2-1000-00 |

| Identify Code |

D2-1000-1-1 |

| Repeat Accuracy | ±0.2mm |

|

Max. Speed* |

100 P/M |

| Working Range |

1000X360mm |

| Max Load |

3000g |

| Structure Type | Two Axes in Parallel |

| Power Requirement | 220V/2000W/50/60Hz/10A |

| Packing Dimension(mm) | 1200(L)X1000(W)X500(H) |

| Gross Weight | 70kg |

| *: Depends on product shape, product density, target weight, etc. | |

Application

Ideal for automatic material handling, palletizing, and packing operations along horizontal conveyor lines or across multiple workstations. A third axis can be optionally integrated to enable flexible control over material rotation and positioning.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About After Sales Support

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

C2000 High-Speed Check Weigher for Precise and Fast Weight Testing

Automatic 8-Track Electronic Counting and Filling Packaging Machine

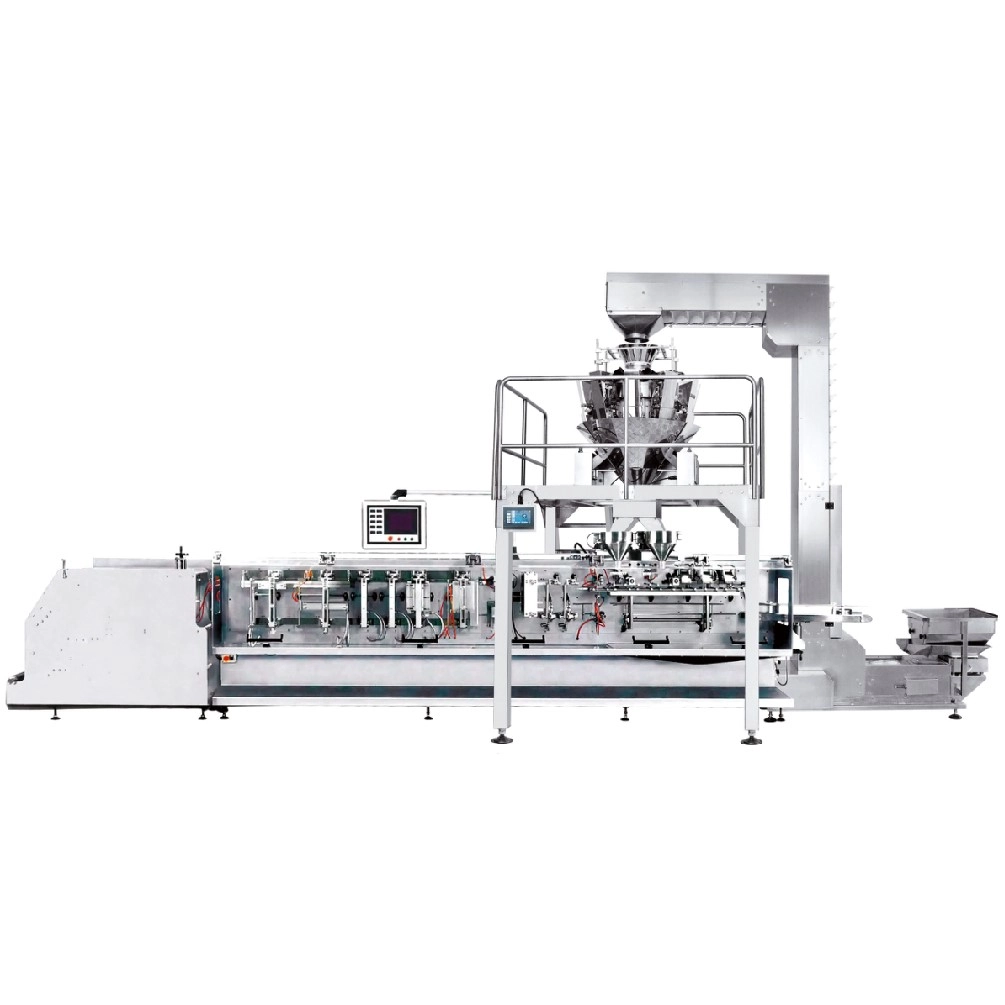

Economic Premade Pouch Weighing And Packing Machine System JW-B15

8-Head Fruit Linear Weigher for Accurate and Efficient Fruit Weighing

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei