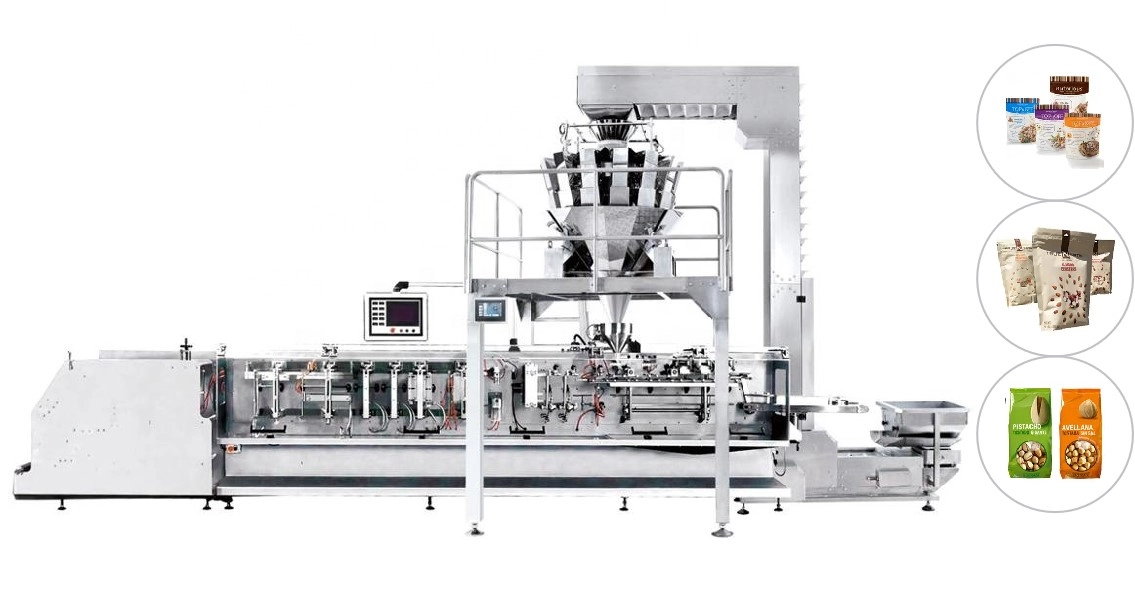

Automatic Premade Pouch Weighing and Filling Machine for Snacks Pet Food JW-B13

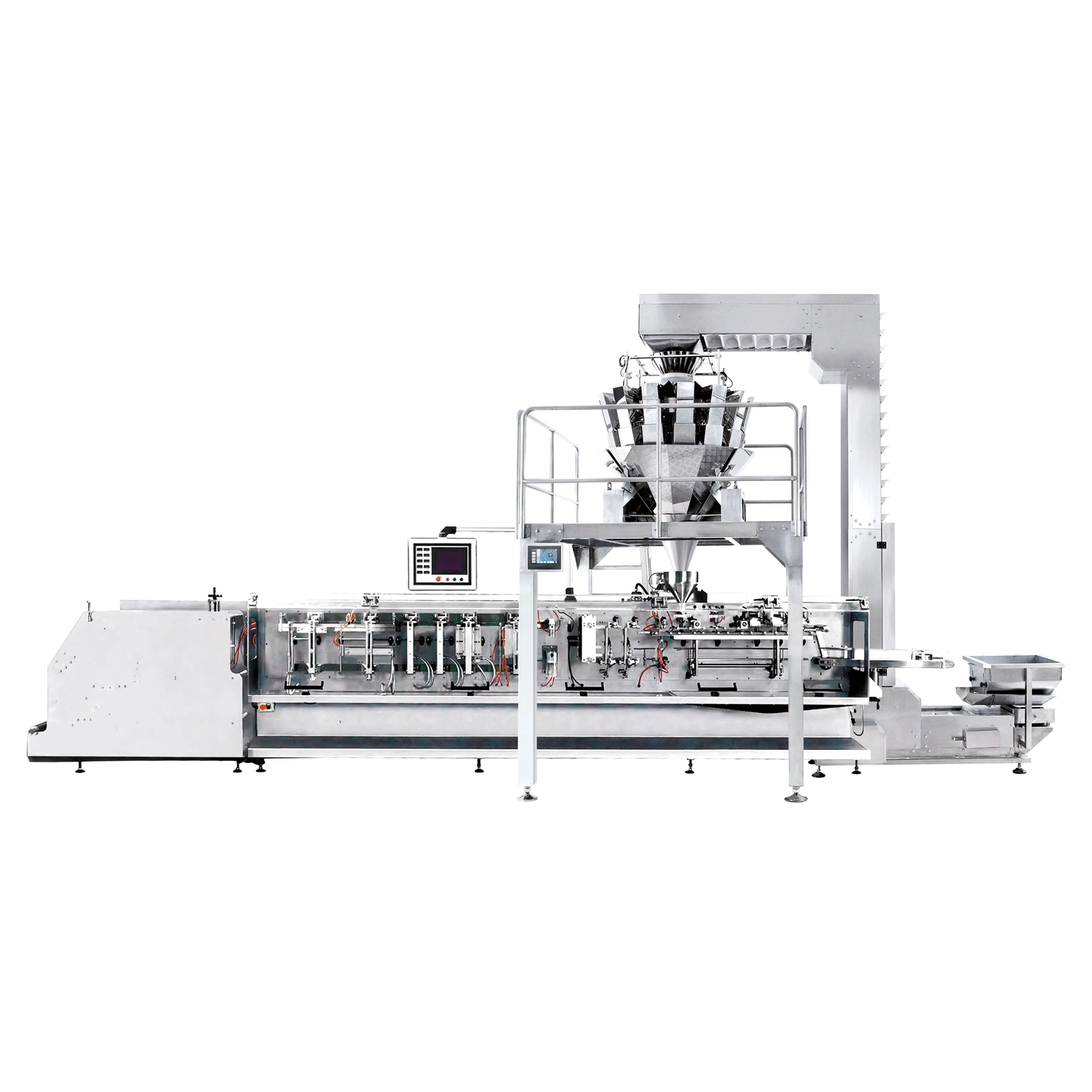

The JW-B13 Standard Pre-Made Bag Packing Machine is an advanced weighing and packing system ideal for granules, slices, and irregular products like snacks, nuts, pet food, and hardware. This fully automated line includes a vibrator feeder, Z conveyor, working platform, multihead weigher, and horizontal packing machine. It ensures high weighing accuracy, fast packing speed, and premium bagging quality—perfect for efficient, stable, and precise packaging.

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | Supply Ability | 500 sets/year |

Feature

-

● System Including: vibrator feeder, Z conveyor, working platform, multi-head weigher, and horizontal packing machine.

-

● Fully automated process, handling everything from feeding and weighing to date printing and finished product output.

-

● Versatile and suitable for a wide range of materials.

-

● High precision in weighing and exceptional efficiency.

-

● Designed for pre-made bags, offering stable operation, fast speed, high

-

production efficiency, and attractive bagging quality.

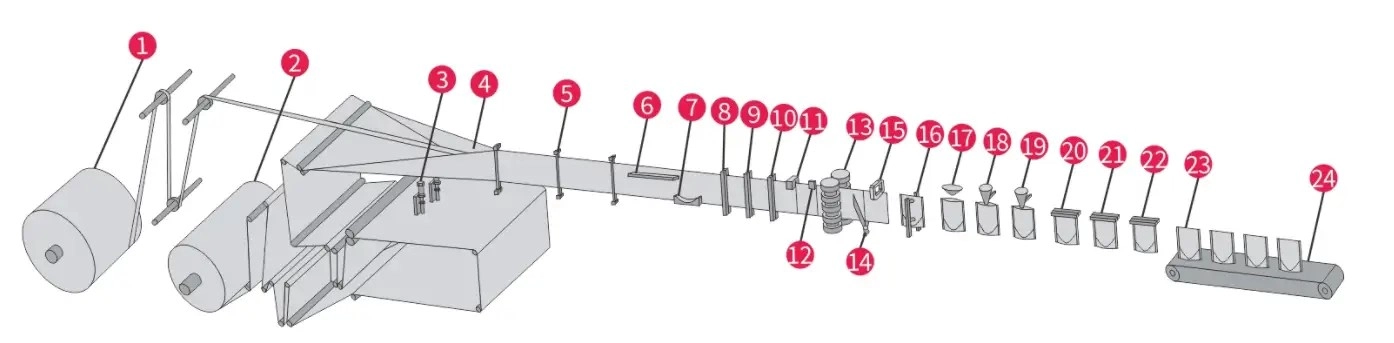

Horizontal Pouch Packing Machine Process Flow Diagram

| 1. Zipper Device | 2. Film Device | 3. Bottom Hole Maker | 4. Forming | 5. Film Guider | 6. Horizontal Zipper Sealing |

| 7. Bottom Sealing | 8. Vertical Sealing 1 | 9. Vertical Sealing 2 | 10. Vertical Sealing 3 | 11. Easy Tear Maker | 12. Color Marks Sensor |

| 13. Servo Motor Puller | 14. Cutting | 15. Bag Holder | 16. Bag Opening | 17. Air Blowing | 18. Filling 1 |

| 19. Filling 2 | 20. Ready to Seal | 21. Hot Sealing | 22. Cool Sealing | 23. Finished Product | 24. Finished Product Output |

Application

It is ideal for weighing rolled, irregular granules, and sliced products such as candies, seeds, jellies, French fries, coffee beans, peanuts, puffed foods, biscuits, chocolates, nuts, pet food, hardware, and more.

Bag Type

Include: 3-side seal bag, 4-side seal bag, flat bag, flat bag with zipper, stand-up bag with zipper, special flat bag, and special stand-up bag, and more.

Optional Equipment

It is designed to inspect the weight of packaged bags and boxes, automatically identifying and rejecting any items that do not meet the preset weight standards using a rejection mechanism.

It is widely applied in industries such as food, pharmaceuticals, chemicals, textiles, apparel, toys, and rubber. It is an ideal solution for meeting HACCP standards in the food industry and GMP compliance in pharmaceutical production.

Throat Metal Detector

This equipment is specifically applied for inspecting and detecting powders, granules, and sheet materials. It ensures precise and reliable quality control, making it ideal for use in food, pharmaceutical, chemical, and related industries.

It is widely applied in the food, pharmaceutical, chemical, textile, clothing, toy, and rubber industries. As a top choice for HACCP compliance in the food sector and GMP standards in the pharmaceutical field, it ensures high-level quality control and safety.

Rotary collecting table

Designed for collecting products from the production line, this equipment is ideal for operations requiring manual handling or temporary storage before the next packaging stage. Perfect for improving workflow efficiency in various processing environments.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About products customization

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

Box-Type Weighing and Packaging Machine for Snack Foods and Puffed Products JW-B25

Automatic Weighing and Canning Filling System for Efficient Packaging Solutions JW-B24

Two-outlet semi-auto weighing and packing system with inclined conveyor JW-B17

Double Feeding Vertical Snack Packing Machine for Factories with Height Restrictions JW-B3

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei