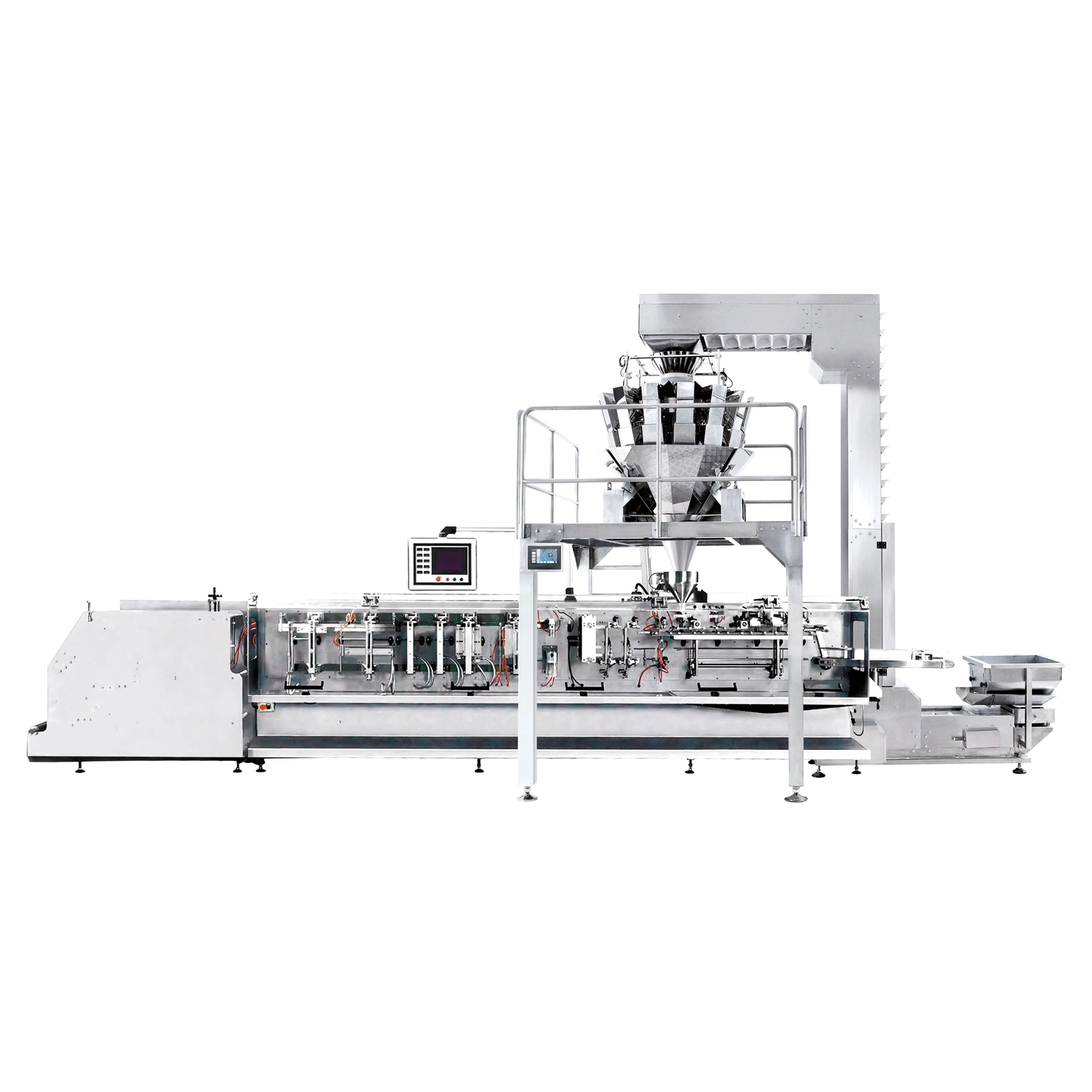

Box-Type Weighing and Packaging Machine for Snack Foods and Puffed Products JW-B25

This fully automatic box-type weighing and packing machine is designed for high-precision, high-efficiency packaging of snack foods, puffed products, and granular materials. The system integrates an automatic box dropper, inclined conveyor, multihead weigher, filling and labeling units, ensuring seamless feeding, weighing, filling, printing, and labeling. Ideal for candy, nuts, seeds, jelly, and more. Customizable to meet diverse production needs.

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | Supply Ability | 500 sets/year |

Feature

● System Including:The system includes an automatic box-dropping device, inclined conveyor, multi-head weigher, working platform, filling machine, and finished product transport system.

-

● Fully automated processes, including feeding, weighing, filling, date printing, and labeling.

-

● High precision: Doubling the outlet efficiency for improved performance.

-

● Versatile and suitable for a wide variety of materials.

Other Mixing Formula Weighing System can be customized

| Series model | Typical Machine | Speed | Max weight |

| Single-box packaging system | 10 head multihead weigher | 35p/min | 1000g |

| One divides into two box packaging system | 14 head multihead weigher | 60p/min | 800g |

Meal Box

This fully automatic box weighing and packaging machine is compatible with various box types, making it an ideal solution for food packaging.

Application

This system is ideal for weighing a variety of snacks, including candy, melon seeds, jelly, frozen food, pistachios, peanuts, nuts, almonds, raisins, and more. It is also suitable for puffed foods, hardware, plastic compounds, and other materials, whether granular, flaky, strip-shaped, round, or irregularly shaped.

Optional Equipment

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About Product choice

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

Automatic Premade Pouch Weighing and Filling Machine for Snacks Pet Food JW-B13

Top Modular 10-Head Linear Weigher for Precise Weighing

Thermal transfer printer for product packaging

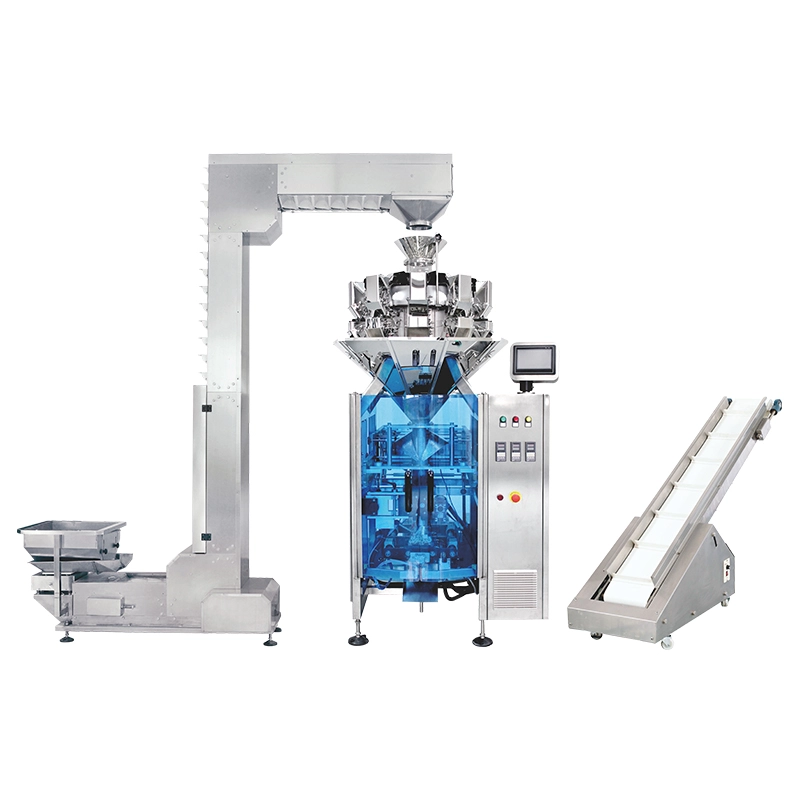

Combined Multihead Weighing Weigher and Packaging Machine with Z Conveyor JW-B4

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei