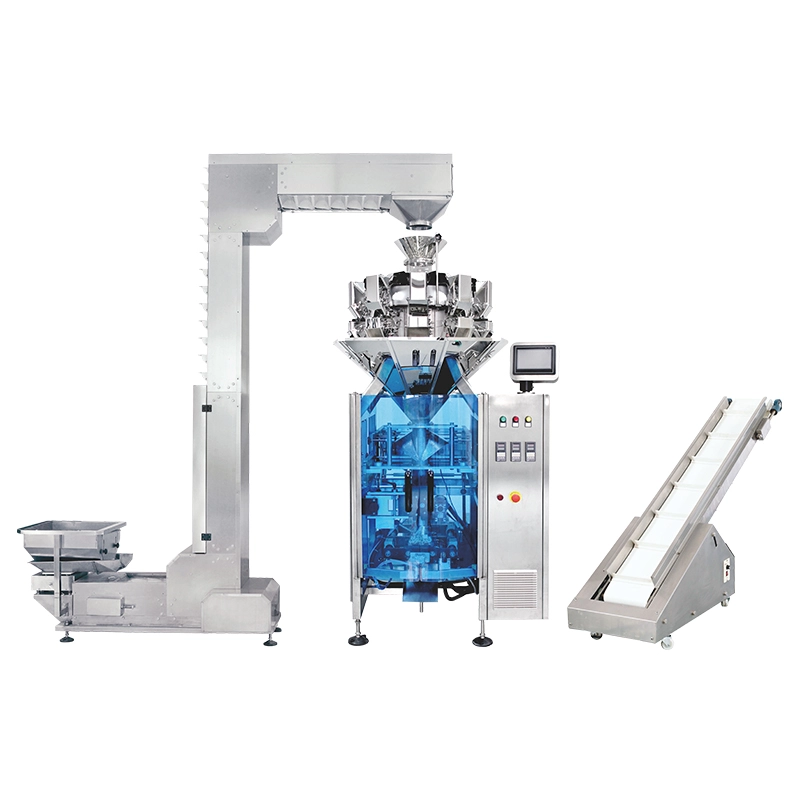

Combined Multihead Weighing Weigher and Packaging Machine with Z Conveyor JW-B4

The JW-B4 Combined Multihead Weighing and Packaging Machine with Z Conveyor is a compact, fully automatic solution ideal for packing snacks, nuts, candies, pet food, frozen products, hardware, and more. It integrates feeding, weighing, filling, sealing, and labeling with high precision and speed. Suitable for a wide range of materials, it’s perfect for space-limited production lines.

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | Supply Ability | 500 sets/year |

System Components

Weighing Machine

The weighing machine (such as a multihead weigher) plays a crucial role in determining the system’s overall economic performance, cost efficiency, and productivity. It offers flexible configuration options, with various combination weigher models available to meet different production needs and material types.

Packaging Machine

The bag forming and material filling process directly impacts the appearance and sealing strength of the bag. It ensures that the final package is both visually appealing and securely sealed, enhancing overall packaging quality and reliability.

Z Conveyor

The double conveyor system is designed for vertical lifting of granular materials such as corn, and is widely used in the food, plastic, and chemical industries. It ensures efficient, reliable material handling, making it ideal for high-demand industrial applications.

Finished Product Conveyor

This machine is designed to transport finished products to checkweighers and the packaging platform, ensuring smooth and efficient transitions in automated production and packaging lines.

Feature

-

● Fully automated operation for feeding, weighing, filling bags, date printing, and finished product output.

● High precision and excellent efficiency.

● Compatible with a wide range of materials.

● A cost-effective solution that reduces overall expenses.

● The compact design of the entire packaging line makes it ideal for use in short workshops.

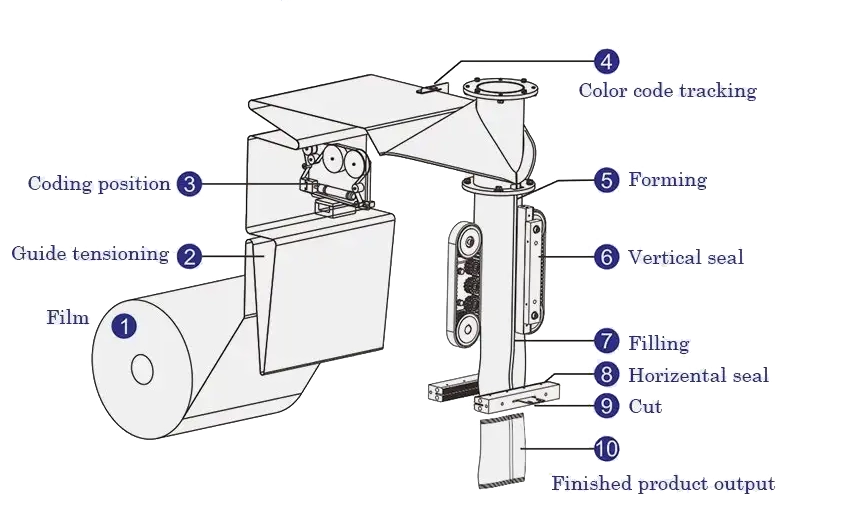

Vffs Process Flow Diagram

-

The VFFS (Vertical Form Fill Seal) process involves a series of precise steps to ensure efficient and accurate packaging. The film is first guided and tensioned, followed by coding and color code tracking for precise positioning. It then passes through the forming tube, where vertical sealing occurs. After filling the product, the machine performs horizontal sealing, cutting, and outputs the finished package.

Application

It is suitable for weighing granule,slice,roll or irregular shape products such as candy,seed,jelly,fries,coffee granule,

peanut.puffy food,biscuit,chocolate,nut,pet food,frozen feeds,etc,It is also suitable for weighing small hardware and plastic components.

Packing Pouch

This packaging system can be used with a variety of bag types, including:3-side seal pouch,4-side seal pouch,flat bag,pillow bag,gusset bag,quad-seal box bag, etc.

Optional Equipment

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About Solution suggestions

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About products customization

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

14-Head Advanced Multihead Weigher 3L for Precise Weighing and Packaging

Double inlet rotary packaging and weighing system JW-B9

24-Head Multihead Weigher with Memory Bucket for Accurate Weighing

Horizontal Packaging Machine With Multihead Weigher for Weighing Pet Foods Puffy Foods B11

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei