Horizontal Packaging Machine With Multihead Weigher for Weighing Pet Foods Puffy Foods B11

Horizontal Packaging Machine With Multihead Weigher for Weighing Pet Foods Puffy Foods B11 is a fully automatic solution for high-speed, high-accuracy packaging. Ideal for snacks like candy, jelly, nuts, and puffed food, as well as hardware and plastic granules in various shapes. It supports premade bags with firm, attractive sealing. Designed for customers needing high production efficiency and large output capacity.

| Supply Ability | 1000sets/year | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7~30days |

| Start Port | Zhongshan port | ||

System Components

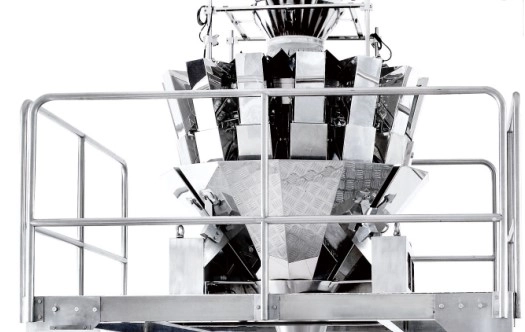

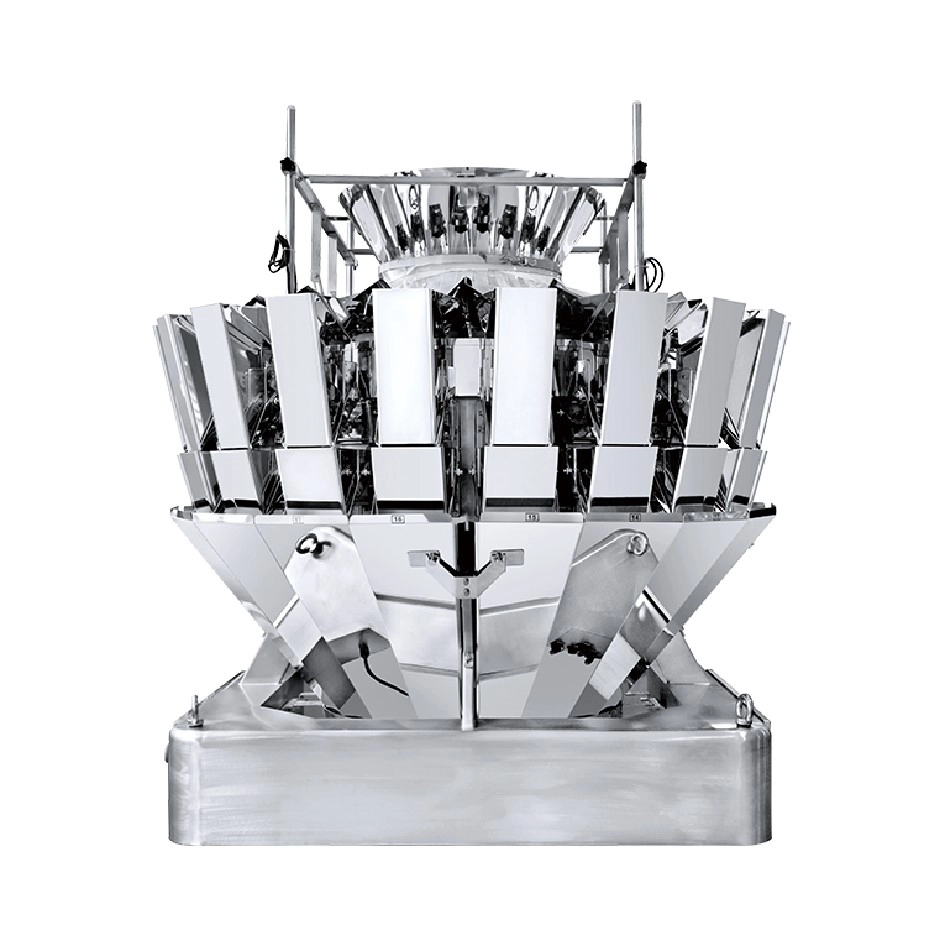

Weighing Machine

The weighing machine (such as a multihead weigher) plays a crucial role in determining the system’s overall economic performance, cost efficiency, and productivity. It offers flexible configuration options, with various combination weigher models available to meet different production needs and material types.

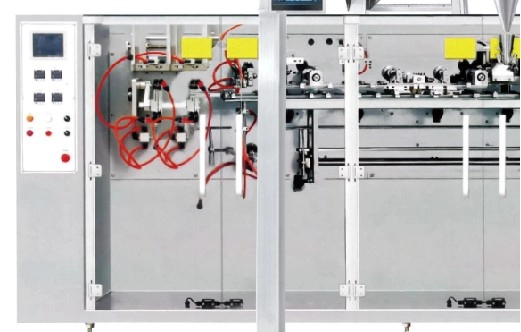

Packaging Machine

The bag forming and material filling process directly impacts the appearance and sealing strength of the bag. It ensures that the final package is both visually appealing and securely sealed, enhancing overall packaging quality and reliability.

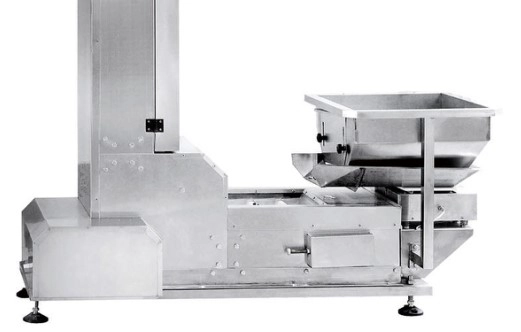

Z Conveyor

The double conveyor system is designed for vertical lifting of granular materials such as corn, and is widely used in the food, plastic, and chemical industries. It ensures efficient, reliable material handling, making it ideal for high-demand industrial applications.

Working Platform

The platform features a compact, stable, and secure design, equipped with a safety guardrail and access ladder, ensuring reliable support for packaging and weighing systems in industrial applications.

Feature

● Fully automated process for feeding, precise weighing, bag filling, date printing, and finished product output.

● Outstanding accuracy and exceptional efficiency.

● Perfectly compatible with a diverse range of materials.

● Ideal for premium-quality packaging of premade bags.

● Reliable, strong, and seamless sealing performance.

● High-speed operation, designed to meet the needs of customers seeking high production capacity and optimal efficiency.

Application

This system is highly effective for weighing a variety of snack foods such as candies, melon seeds, jelly, frozen foods, pistachios, peanuts, nuts, almonds, raisins, and more. It is also perfect for handling puffed foods, hardware, plastic components, and materials in granular, flaky, strip, round, or irregular shapes.

Bag Types

This packaging system can be used with a variety of bag types, including:3-side seal pouch,4-side seal pouch,flat bag, flat&zipper bag,stand bag,stand&zipper bag,doypack shape,flat pouch shape,etc.

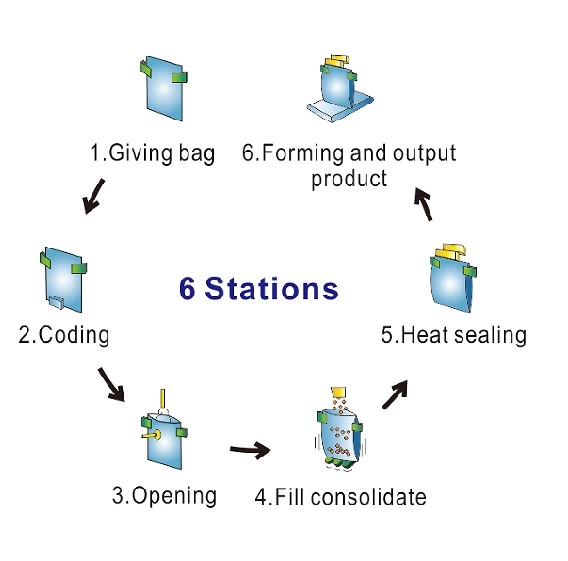

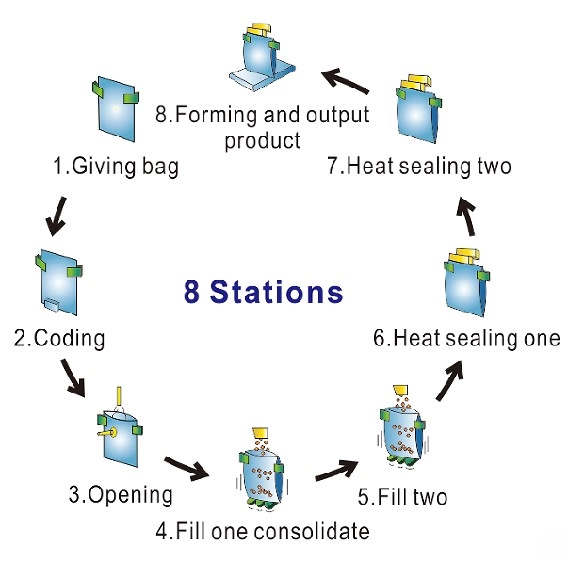

Rotary Packing Machine Process Flow Diagram

6 STATIONS

This system is specifically designed to accommodate standard bags and is ideal for dispensing stickless and dust-free products. Whether you're packaging food, pet supplies, or other dry goods, our advanced feeding system ensures a clean, efficient, and reliable process. With our automated equipment, you can optimize production, reduce labor costs, and deliver high-quality, professional packaging every time.

8 STATIONS

It is designed to handle a wide range of challenging products. Whether you're dealing with fluffy, irregular, lamellate, lumpy, easy-to-jam, sticky, or dusty items, our system can effectively and efficiently feed them into zipper pouches and shaped pouches. You can trust that our technology will ensure a smooth and reliable feeding process, regardless of the unique characteristics of your products.

Optional Equipment

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Solution suggestions

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

About Product choice

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

20-Head Multihead Weigher with Dual Output for Efficient Weighing of Mixed Products

Multi Head Combination Weigher with Intelligent Feeding Control

Automatic Weighing and Canning Filling System for Efficient Packaging Solutions JW-B24

Double feeder horizontal packaging and weighing system JW-B12

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei