Thermal transfer printer for product packaging

The thermal transfer overprinter features a unique ribbon cassette reel design and is compatible with DC24V power supply from packaging equipment, eliminating the need for an external power box. Its compact, integrated structure makes it ideal for various flat flexible packaging films such as PE, PVE, and aluminum foil. Suitable for intermittent thermal transfer coding on packaging machines, conveyor lines, and other equipment.

| Print Head | 53mm | Printing Area | 75(L) X 53(W)mm |

| Print Speed | 160 times/min | Supply Ability | 5000sets/year |

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | ||

Feature

● Easily create and edit label files—such as text and date—using intuitive editing software.

● Date and other coding characters can be customized based on user requirements.

● Supports printing of barcodes, QR codes, images, and tables.

● Compatible with a wide range of Chinese and English vector fonts to meet personalized design needs.

● Allows USB file import and network connectivity for seamless content transfer from other devices.

● Offers flexible and reliable I/O input/output control.

● Supports USB file export/import and motherboard software updates for enhanced performance.

Mechanical Character

Technical Specification

| Model | JW-DM3275 | JW-DM5375 | JW-DM3275R | JW-DM5375R |

| Identify Code | DM3275-1-1 | DM5375-1-1 | DM3275R-1-1 | DM5375R-1-1 |

| Printing Area (mm) | 68(L) x 28(W) | 68(L) x 48(W) | 68(L) x 28(W) | 68(L) x 48(W) |

| Print Speed* | 160 times/min | |||

| Max Ribbon length | 600m | |||

| Label Adaptability | ART、 PE、 PET、 PVC | |||

| Film | 软包材PE、 PP、 PVC等 | |||

| Power Requirement | 220V / 240W / 50/60Hz / 1.2A | |||

| Packing Dimension (mm) | 650(L)x350(W)x350(H) | |||

| Gross Weight | 22kg | |||

|

*: Depends on the size of the printed label, the longer the speed is slower. |

||||

Application

This thermal transfer overprinter is ideal for use with various smooth flexible packaging materials such as PE, PVE, aluminum foil, labels, and coated paper. It can be seamlessly integrated into packaging machines, conveyor lines, and other automated equipment.

Note: This device is not suitable for irregular surfaces such as bottles, cans, rough paper, or other uneven objects.

Model Selection

● Refer to the right "installation diagram", according to the film pulling direction, the direction of replacing the ribbon (handle), the rotation direction of the ribbon, and outlet direction, select the suitable printer model.

● For other directions than those shown in the installation diagram, please consult our technician.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Solution suggestions

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

About products customization

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

About Price and payment

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

8-Head Fruit Linear Weigher for Accurate and Efficient Fruit Weighing

Double Column Check Weigher for Accurate Material Weight Testing and Automatic Sorting

Z Type Bucket Conveyor for Food Conveying and Handling Applications

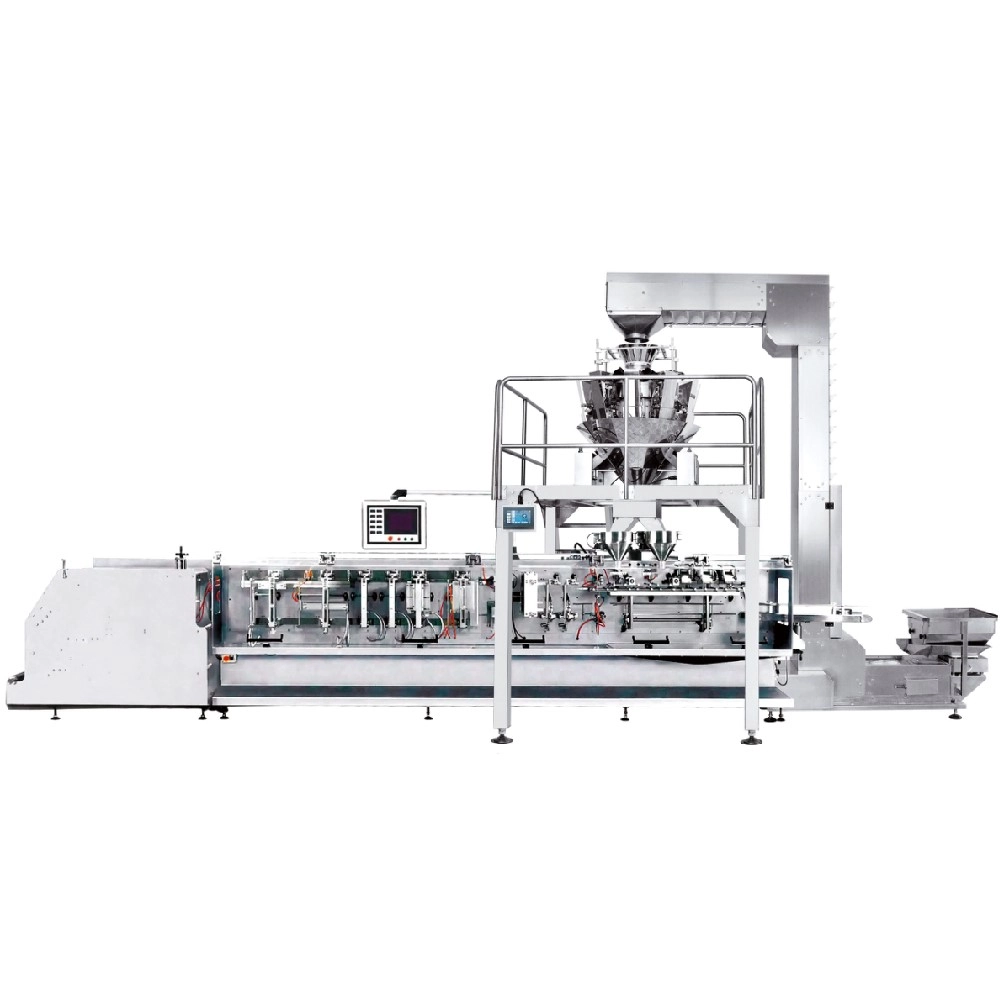

Weighing and packing systems with double inlet pre-made bag packing machines JW-B14

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei