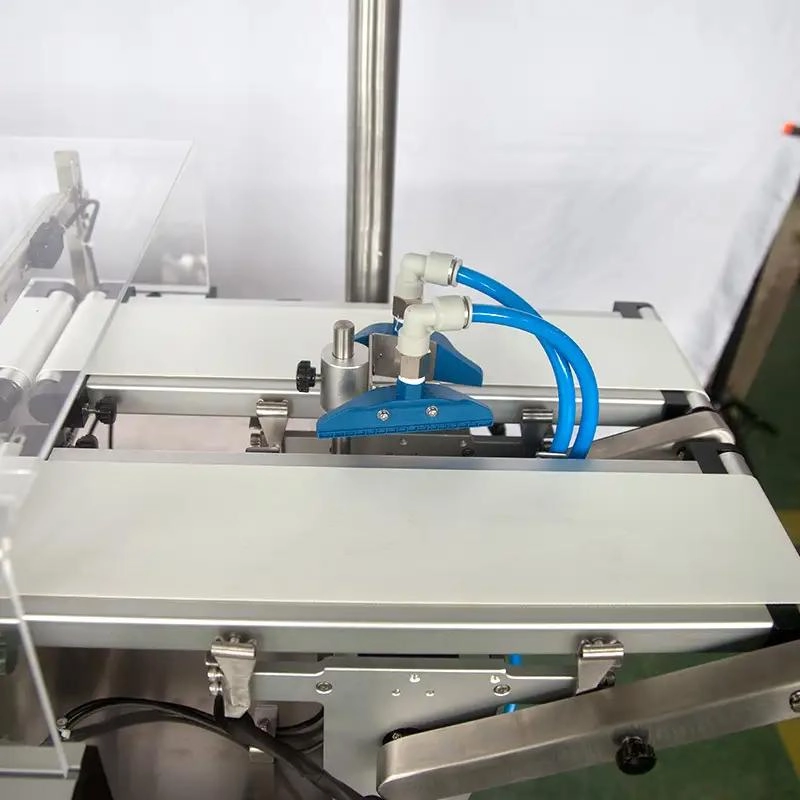

Double Column Check Weigher for Accurate Material Weight Testing and Automatic Sorting

The equipment is equipped with two independent conveyor lines, which do not interfere with each other in measurement. It adopts a new modular control system with an accuracy of up to 0.2g and a fault alarm text prompt. The conveyor structure is designed to be easily disassembled for easy cleaning and maintenance. At the same time, it provides comprehensive production quality statistics, including weight distribution bar graphs, total weight, number of qualified packages, qualified rate, number of unqualified packages and corresponding time, etc., to improve production management efficiency.

| Supply Ability | 1000 sets/year | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | ||

Feature

● The two Independent, non-interfering delivery lines for precise operation.

● Advanced modular control system with a precision of 0.2g and fault alarm displayed via text.

● Conveyor structure designed for easy disassembly, facilitating quick cleaning and maintenance.

● Comprehensive production quality statistics, including weight distribution charts, total weight, qualified package count, qualification rate, non-conforming package count, actual weight, and production time of unqualified products.

Mechanical Character

Technical Specification

| Model | JW-C200(C6 Double) |

| Identify Code | C200-2-4 |

| Weighing Range | 5-200g |

| Accuracy*1 | XIII(1) |

| Max Speed*2 | 140PCS |

| Belt Size(mm) | 320(L)X100(W) |

| Control Panel | 10.1” Touch Screen |

| Reject Method | Air Blowing |

| Max Belt Speed | 20m/min |

| Power Requirement | 220V/800W/50/600Hz/4A |

| Packing Dimension(mm) | 1640(L)X590(W)X830(H) |

| Gross Weight | 162kg |

| *1: Can refer to the national standard GB/T27738-2011 or the international Legal Organization No.61 International Recommendation OIML R61 2004(E) | |

| *2: Depends on product shape, product density, target weight, etc. When the speed is higher than 140 p/min, it needs to change with a special modular board. | |

Application

Ideal for material weight testing in industries such as food, pharmaceuticals, meat, seafood, candy, condiments, and more. Capable of detecting two products with different weights simultaneously, the sorting device automatically removes substandard items for improved quality control.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Cooperation Process

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

About Solution suggestions

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

About After Sales Support

How about the after-sales service?

Warranty :2 years

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

Food Metal Detector Manufacturer For Reject Defective Products G5020

C2000 High-Speed Check Weigher for Precise and Fast Weight Testing

Automatic Dual-Axis Industrial Robotic Arm for Packaging and Production Automation

High Sensitivity Horizontal Metal Detector for Food and Pharmaceutical Industries

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei