Semi Automatic Vacuum Feeding Linear Weigher System for Powder and Small Granules Weighing JW-B19

The Kenwei JW-B19 Semi-Automatic Vacuum Feeding Linear Weigher is ideal for precise weighing of powders and small granules like sugar, salt, rice, coffee, and milk powder. With full automation, high accuracy, and space-saving design, it boosts efficiency while reducing labor and cost. Perfect for industries needing reliable, flexible, and compact weighing solutions.

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | Supply Ability | 500 sets/year |

Feature

-

● Fully Automated Process: This system efficiently manages the entire workflow—from material feeding to precise weighing and final output—minimizing manual labor and reducing error rates. Advanced sensors and control systems ensure stable, reliable performance and consistent operational results.

-

● High Versatility and Accuracy: Designed to handle a wide range of materials, from fine powders to various granules, the system delivers excellent weighing precision. This is vital for maintaining product quality and meeting regulatory standards, even when operating at high volumes.

-

● Compact and Cost-Efficient: With its space-saving design, the system is ideal for production areas with limited room. By reducing manual handling and enhancing automation, it significantly cuts labor costs and improves overall productivity, offering excellent return on investment.

-

● Wide Material Compatibility: Optimized for both powders and uniformly shaped granules, the system easily adapts to different material properties. Its flexible design makes it a reliable solution for manufacturers working with a diverse range of product types across various industries.

- ● Affordable and Versatile: This system delivers outstanding value for money, making it a smart investment for companies needing reliable weighing performance. It's particularly suited for bag types that traditional packaging machines can't handle, offering a cost-effective yet advanced solution.

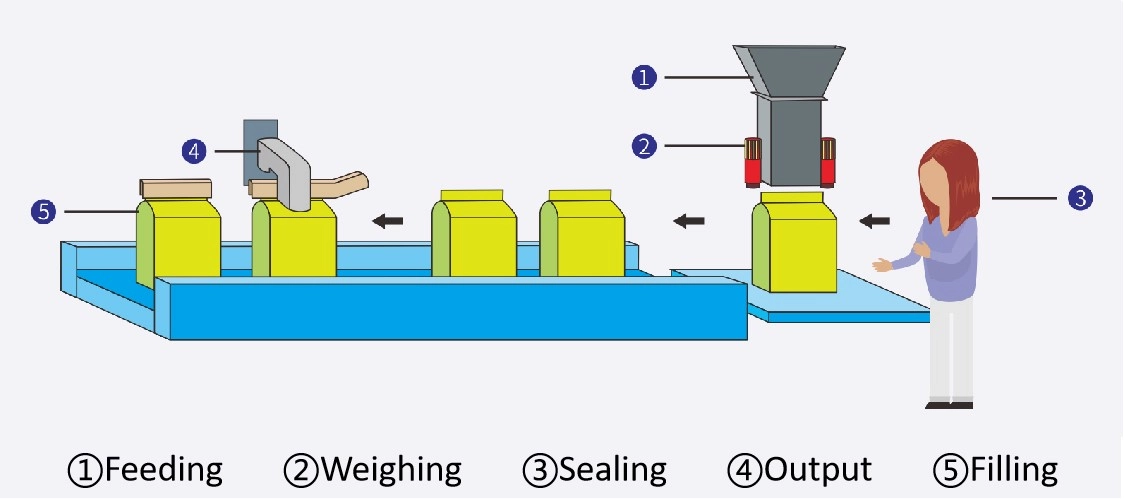

Manual Packing System Process Flow

- The Manual Packing System follows a streamlined process: feeding, weighing, filling, sealing, and output. This setup ensures basic packaging efficiency while allowing flexibility and control, ideal for small-scale or customized production operations.

Series Models

Application

It is ideal for weighing powdered and rolled or uniformly shaped granules, including sugar, salt, seeds, rice, sesame, monosodium glutamate, milk powder, coffee, seasoning powder, and more.

Optional Equipment

Check weigher

Eliminates products that don’t meet weight standards, sorts them, and generates statistical data. (if already equipped with other weight detection equipment then no need use this machine)

Horizontal Metal Detector

Used to detect any metal contamination that may have occurred during the production process. It is ideally placed after packaging is complete.(if already equipped with other weight detection equipment then no need use this machine)

Metal Detector with Check weigher

Combines metal detection and weight checking in one unit, reducing costs and minimizing commissioning and maintenance time.

Finished product conveyor

Utilized to transport the product to the next stage of the process.

Throat Metal Detector

Detects metal contamination before packaging, installed between the weigher and packaging machine for space efficiency.(if already equipped with other weight detection equipment then no need use this machine)

Customer Cases

-

-

The high-speed 4-head linear weigher with vacuum feeder offers an efficient and precise solution for weighing corn kernels. Engineered for accuracy and speed, this system ensures consistent portioning while maintaining smooth production flow. The vacuum feeder improves feeding reliability by preventing blockages and enabling a steady supply of kernels into the weighing unit. Ideal for the food processing sector, it enhances productivity and reduces material waste, making it an excellent choice for bulk packaging tasks.

● Linear Weigher Technology Highlights:

-

Four independent weighing heads for parallel operation.

-

Linear vibration feeders to gently handle product.

-

Smart combination logic for optimized weighing efficiency.

● Advanced Vacuum Feeder Features:

-

Tailored to the unique properties of corn kernels.

-

Adjustable suction to minimize product damage.

-

Anti-blockage design for uninterrupted feeding.

-

Built with food-grade, hygiene-compliant materials.

-

-

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

About Solution suggestions

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

About Cooperation Process

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

Semi Automatic Multi-function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher JW-B20

High speed single head linear weigher for sugar sesame weighing

3 Head Linear Weigher Packaging Machine for Small Granules

Economical Linear Weighing and Vertical Packaging Machine for Powder Products JW-B7

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei