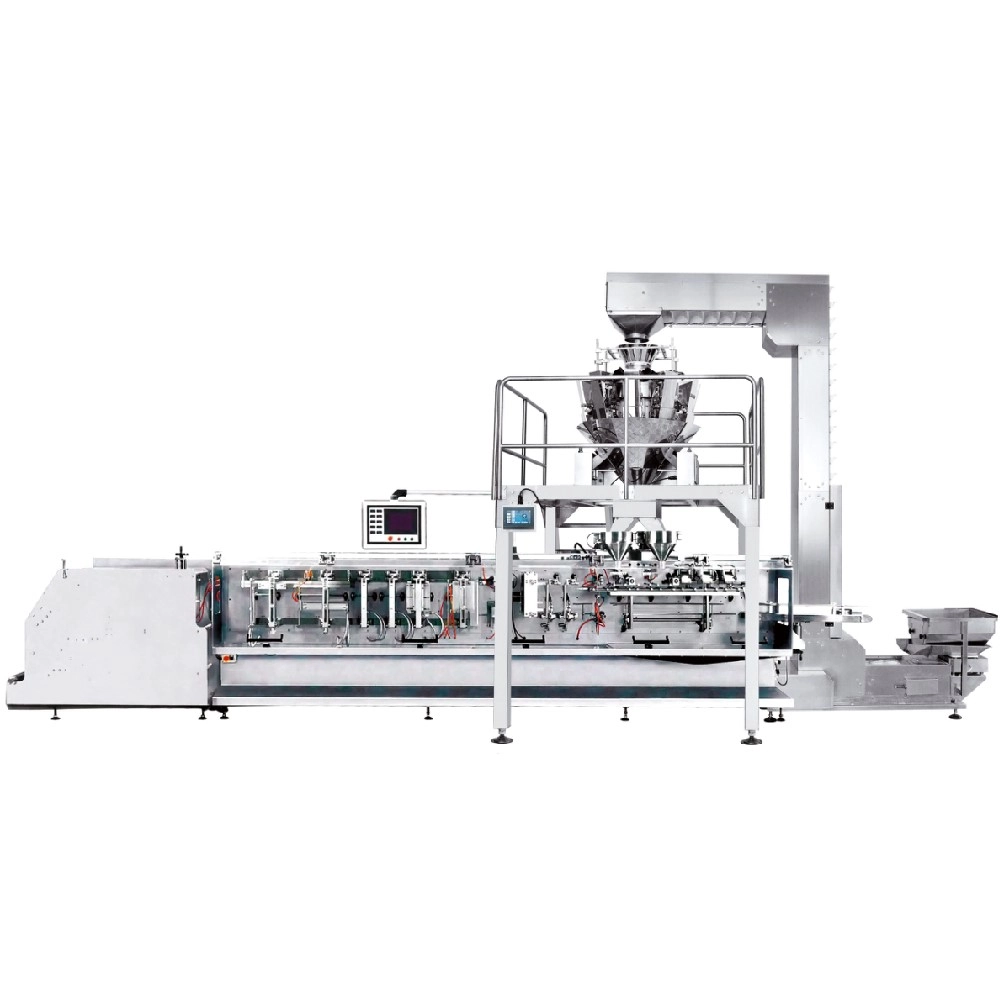

Double Filling VFFS Packaging Machine for Efficient Dual Product Packaging

The Fully Automatic High-Speed Vertical Double Filling Form-Fill-Seal (VFFS) machine features a compact design and a complete range of packaging machines and auxiliary equipment, making it adaptable to various materials and space-efficient. It can handle a wide variety of laminated films, single-layer PE films, film thicknesses ranging from 0.04mm to 0.09mm, and paper membrane packaging. This VFFS machine is widely used in food, pharmaceutical, and chemical industries for packaging snacks, powders, liquids, and granular products. The machine forms bags from flat film rolls, fills them with products, and seals them vertically, improving packaging efficiency and ensuring consistent, high-quality production.

For a variety of laminated films, single-layer PE film, film thickness range 0.09 mm, single PE film, paper Membrane packaging can be applied.The vertical form fill seal machine is a type of packaging machine commonly used in the food, pharmaceutical, and chemical industries. Vffs machine is designed to form a bag from a flat roll of film, fill the bag with product, and then seal it, all in a vertical fashion. The vffs packaging machine is efficient and versatile, capable of handling a wide range of products and bag sizes. It is often used for packaging items such as snacks, powders, liquids, and granular products. The vertical form fill seal machine helps companies streamline their packaging process and ensure the efficient and consistent production of packaged goods.

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | Supply Ability | 2000sets/year |

Feature

● PLC control system with a user-friendly man-machine interface for easy operation and maintenance.

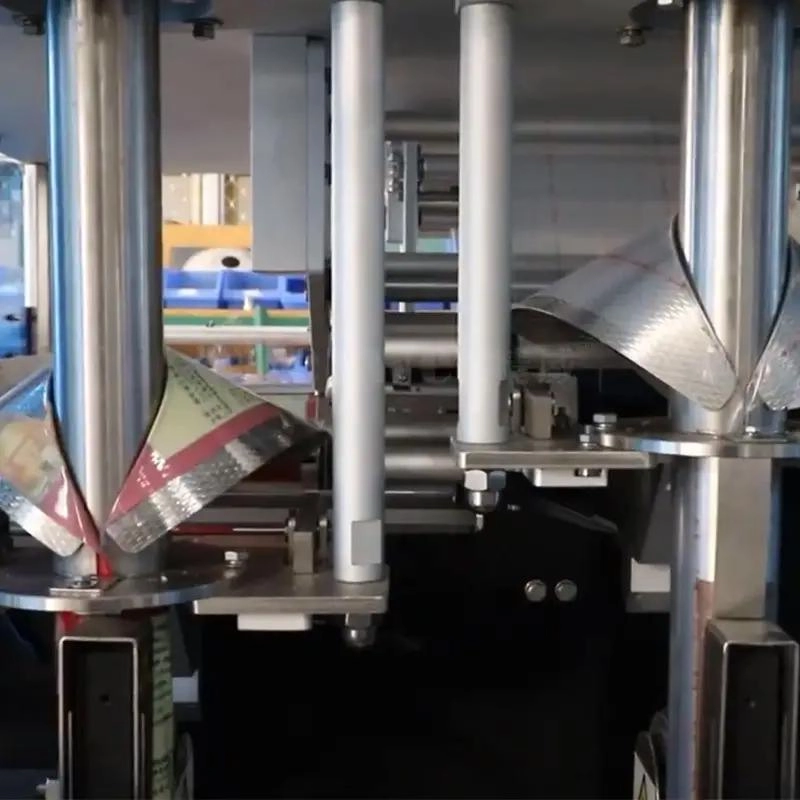

● Servo motors control both the film pulling and horizontal sealing systems for precise performance.

● Optical tracking devices ensure high-speed packing with accurate results.

● The machine frame is constructed from stainless steel #304, featuring an auto-stop protection function when the door is opened for safety.

Technical Specification

| Item No. | JW-HD3830 |

| Film Width | 150~380mm |

| Bag Size Range | L*W=(50~300)*(50~180)mm |

| Packing Speed | 2*90bags/min |

| Film Pulling System | vacuum film pulling system |

| Gas Pression | 0.8MPa |

| Gas Consumption | 0.6m³/min |

| Power Requirement | 6KW/220V/50(60)Hz |

| Machine Size | L*W*H=2050*1850*1915mm |

| Machine Weight | 680KG |

Application

Applicable Bag Type: Pillow Bag – The machine is designed to create and seal pillow-style bags, which are widely used for packaging a variety of products such as snacks, powders, liquids, and granular materials. The pillow bag is popular in industries like food, pharmaceuticals, and chemicals due to its efficient use of space, ease of handling, and versatility in packaging different product types.

Applicable Packing Materials: Ideal for packaging a wide range of products, including snack foods, frozen foods, coffee, oatmeal, granulated sugar, salt, puffed snacks, rice, herbs, tea, small hardware, and more. This machine accommodates diverse materials, ensuring versatile packaging solutions for various industries, such as food, pharmaceuticals, and consumer goods.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Solution suggestions

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

Food Metal Detector Manufacturer For Reject Defective Products G5020

8-Head Fruit Linear Weigher for Accurate and Efficient Fruit Weighing

Weighing and packing systems with double inlet pre-made bag packing machines JW-B14

Economic vertical form fill seal packing machine(VFFS)

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei