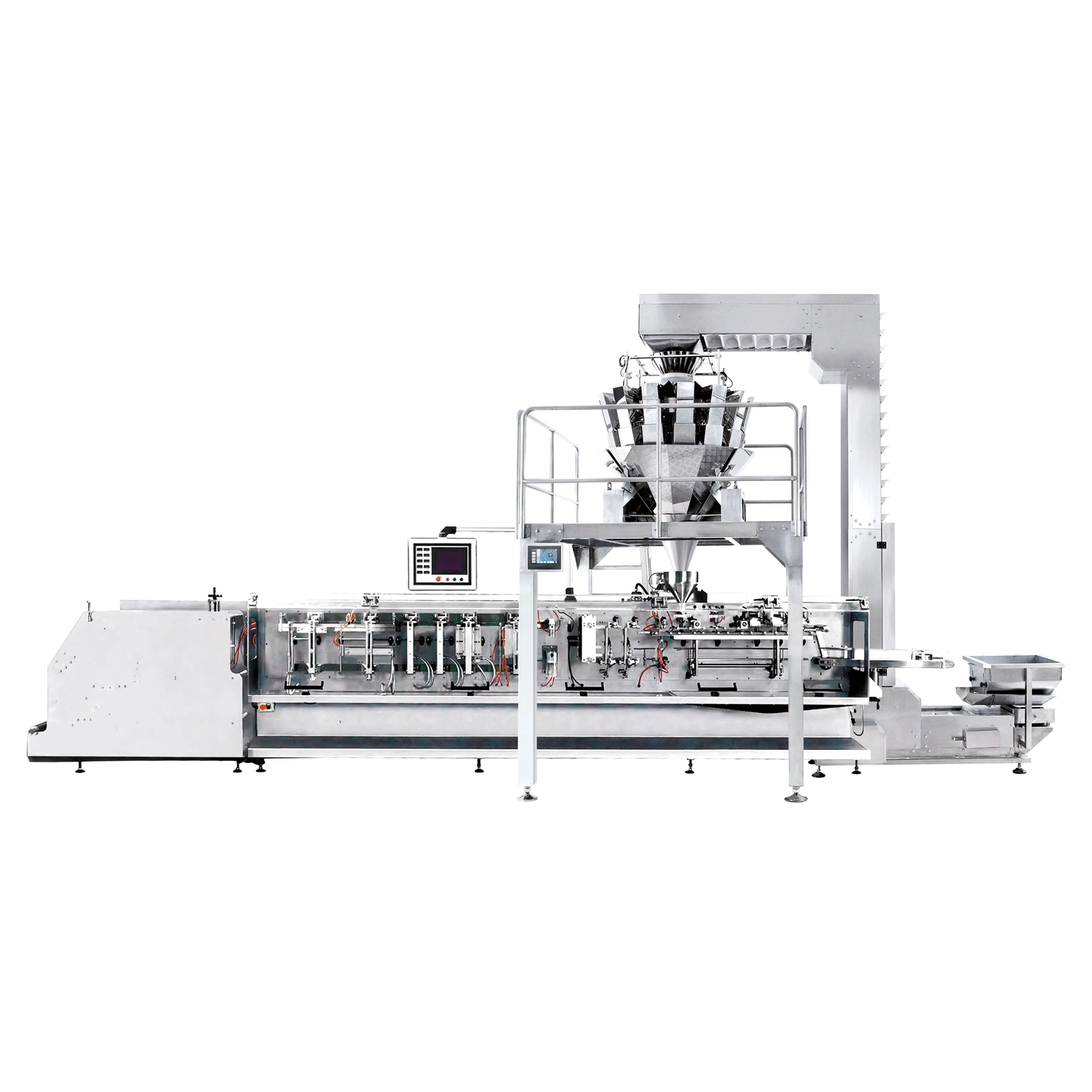

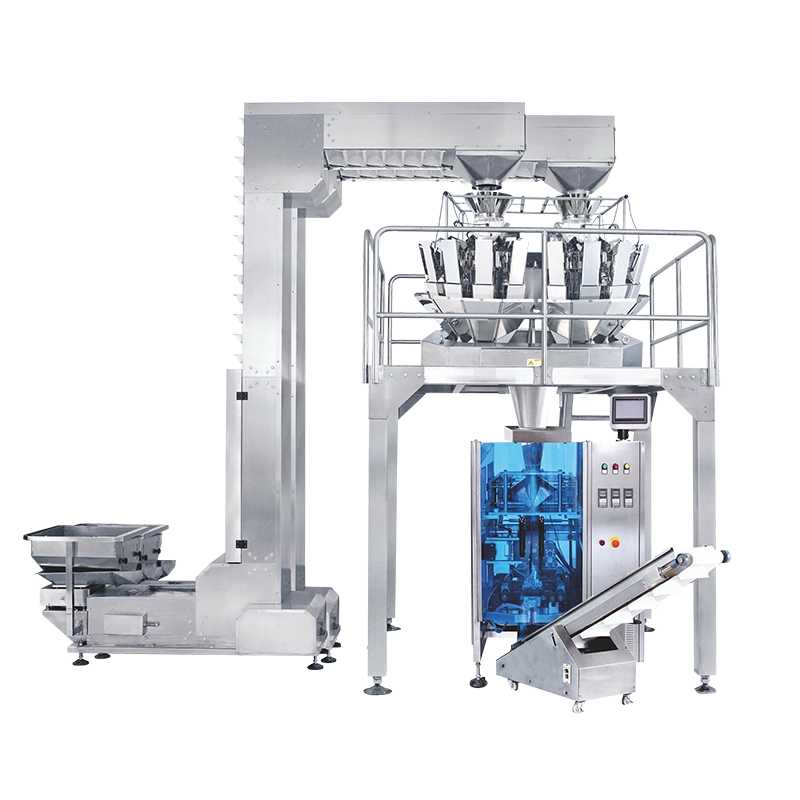

Rotary vacuum packaging and weighing system JW-B10

The JW-B10 Rotary Vacuum Packaging and Weighing System integrates a vibrator feeder, Z bucket conveyor, multi-head weigher, and rotary vacuum packaging machine. It offers high-precision, fully automatic feeding, weighing, vacuum sealing, and output. Ideal for snacks, puffed foods, hardware, and plastic granules, it uses premade bags and delivers excellent vacuum sealing—perfect for products requiring long-lasting freshness.

| Supply Ability | 1000sets/year | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7~30days |

| Start Port | Zhongshan port | ||

System Components

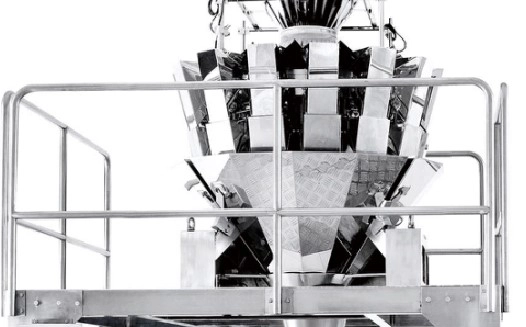

Weighing Machine

The weighing machine (such as a multihead weigher) plays a crucial role in determining the system’s overall economic performance, cost efficiency, and productivity. It offers flexible configuration options, with various combination weigher models available to meet different production needs and material types.

Packaging Machine

The bag forming and material filling process directly impacts the appearance and sealing strength of the bag. It ensures that the final package is both visually appealing and securely sealed, enhancing overall packaging quality and reliability.

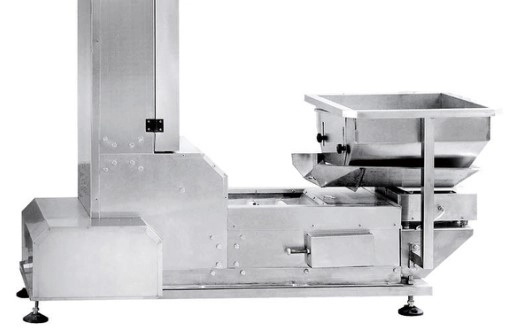

Z Conveyor

The double conveyor system is designed for vertical lifting of granular materials such as corn, and is widely used in the food, plastic, and chemical industries. It ensures efficient, reliable material handling, making it ideal for high-demand industrial applications.

Working Platform

The platform features a compact, stable, and secure design, equipped with a safety guardrail and access ladder, ensuring reliable support for packaging and weighing systems in industrial applications.

Vacuum Feeding Machine

Driven by means of vacuum suction to transmit granular and powdered materials transportation equipment, widely used in pharmaceutical, food, chemical, ceramics.

Feature

● Fully automated packaging system that covers feeding, weighing, bag filling, date printing, and finished product output.

● Designed to meet high standards, ensuring exceptional efficiency and performance.

● Compatible with a wide range of materials for versatile packaging solutions.

● Perfect for packaging premade bags, offering consistent results.

● Delivers excellent vacuum performance, ideal for products that require long-term vacuum preservation.

Application

It is suitable for weighing snack foods such as candy, melon seeds, jelly, frozen, pistachio, peanuts, nuts, almonds, raisins,etc.and is suitable for puffed food; hardware, plastic compounds and other granular, flaky, strip, round and irregular shape material.

Bag Types

This packaging system can be used with a variety of bag types, including:3-side seal pouch,4-side seal pouch,flat bag, flat&zipper bag,stand bag,stand&zipper bag,doypack shape,flat pouch shape,etc.

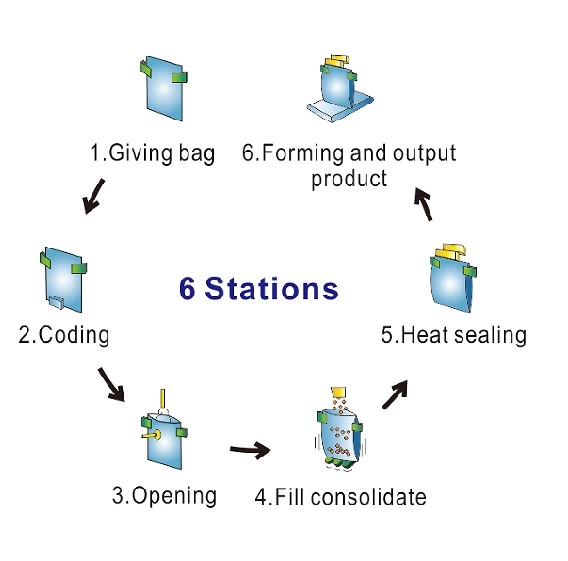

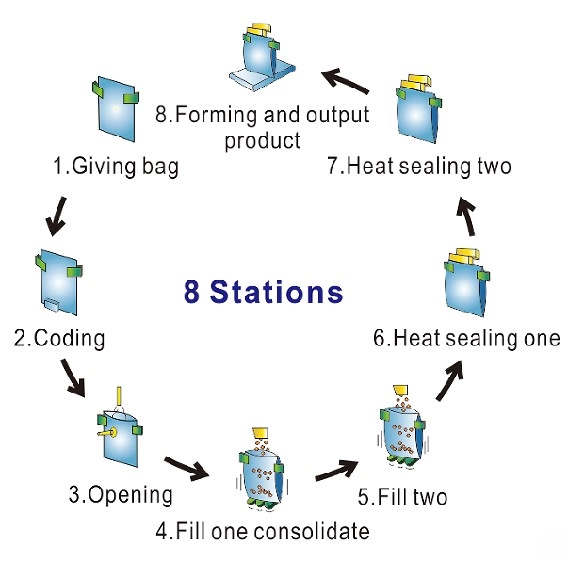

Rotary Packing Machine Process Flow Diagram

6 STATIONS

This system is specifically designed to accommodate standard bags and is ideal for dispensing stickless and dust-free products. Whether you're packaging food, pet supplies, or other dry goods, our advanced feeding system ensures a clean, efficient, and reliable process. With our automated equipment, you can optimize production, reduce labor costs, and deliver high-quality, professional packaging every time.

8 STATIONS

It is designed to handle a wide range of challenging products. Whether you're dealing with fluffy, irregular, lamellate, lumpy, easy-to-jam, sticky, or dusty items, our system can effectively and efficiently feed them into zipper pouches and shaped pouches. You can trust that our technology will ensure a smooth and reliable feeding process, regardless of the unique characteristics of your products.

Optional Equipment

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

Automatic Premade Pouch Weighing and Filling Machine for Snacks Pet Food JW-B13

Horizontal Packaging Machine With Multihead Weigher for Weighing Pet Foods Puffy Foods B11

Single Multihead Weigher Mixing And Weighing Packaging System For Weighing Packaging Mixing Materials JW-B26

Double inlet rotary packaging and weighing system JW-B9

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei