Single Multihead Weigher Mixing And Weighing Packaging System For Weighing Packaging Mixing Materials JW-B26

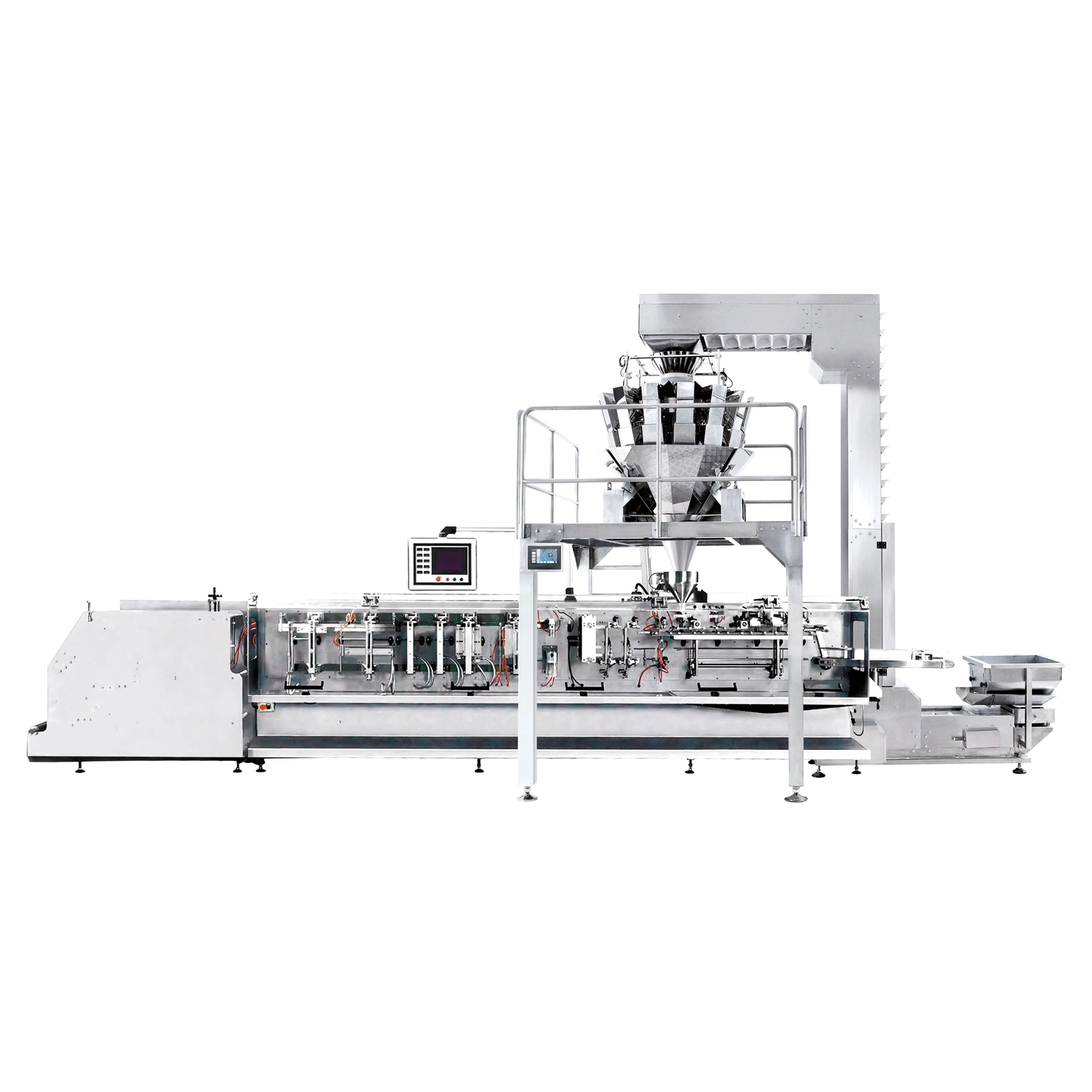

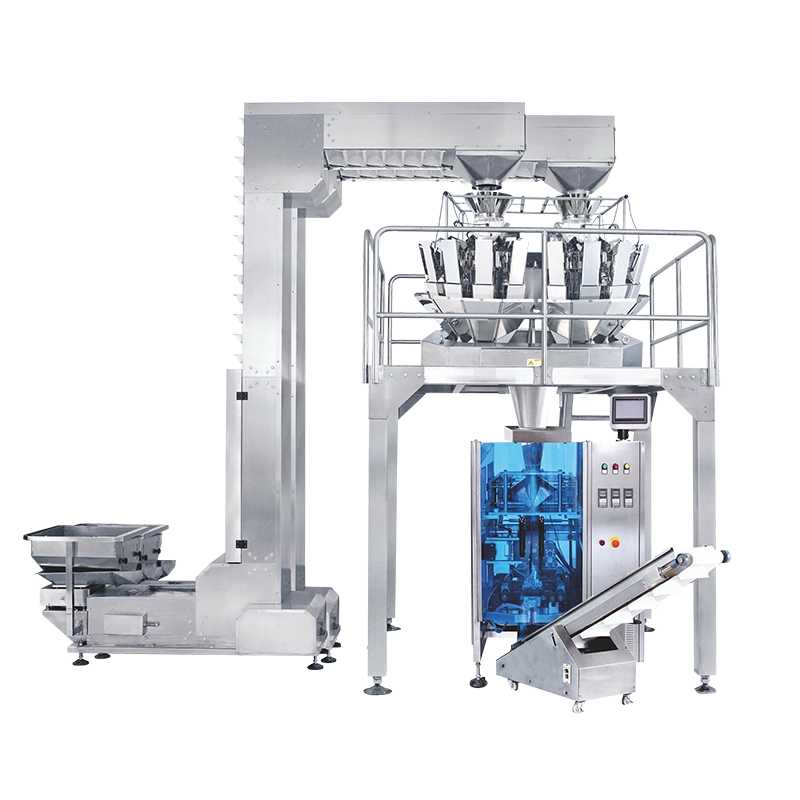

The Kenwei JW-B26 Single Multihead Weigher Mixing and Packaging System offers fully automated operation, completing feeding, weighing, filling, date printing, and product output with high accuracy and speed. Ideal for granules, slices, irregular shapes, and mixed products like candy, nuts, snacks, pet food, and even small hardware. Its versatility and precision make it a perfect solution for diverse packaging needs.

| Supply Ability | 1000sets/year | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 30days |

| Start Port | Zhongshan port | ||

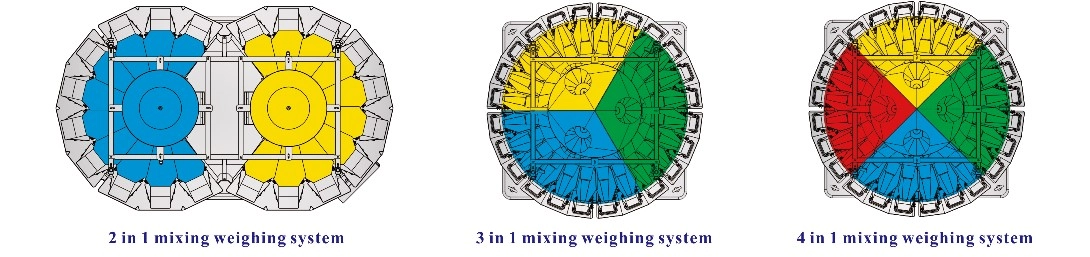

Mixing Weighing System

| Series model | Typical Machine | Speed | Max weight |

| 2-in-1 mixing weighing system | 20 Head Weigher | 60p/min | 2000g |

| 3-in-1 mixing weighing system | 24 Head Weigher | 60p/min | 300g |

| 4-in-1 mixing weighing system | 24 Head Weigher | 60p/min | 240g |

| (32 head) 4-in-1 mixing weighing system | 32 Head Weigher | 60p/min | 400g |

| 2-10 in 1 mixing weighing system | 10 Head Linear Weigher | 50p/min | 1000g |

Feature

System including: Vibrator feeder, Z bucket conveyor, working platform, multi-head weigher, vertical form fill seal machine, finished product conveyor, and dropper metal detector.

-

-

-

● Fully automatic finishing whole process of feeding, weighing, filling bag, date printing,finished product output.

● High accuracy and high speed.

● Applicable to a wide range of materials.

● Applicable to the customer who without special requirements of packaging and material is widely used.

-

-

Application

It is suitable for weighing granule,slice,roll or irregular shape products such as candy,seed,jelly,fries,coffee granule,peanut.puffy food,biscuit,chocolate,nut,pet food,frozen feeds,etc,It is also suitable for weighing small hardware and plastic components.

Packing Puch

The weighing and packaging system is compatible with various bag types, as illustrated in the figure on the right.

Optional Equipment

Check Weigher

Used for checking the weight of products, removing unqualified items, and classifying and recording product statistics.

Horizontal Metal Detector

Detects both magnetic and non-magnetic metals mixed with products during the production process, ideal for post-packaging detection.

Dropped Metal Detector

Detects both magnetic and non-magnetic metals in products during production. This device is designed for pre-packaging detection and is positioned between the bottom of the weigher and the top of the VFFS feeding funnel, saving space but increasing the system's height.

Combined Check Weigher And Metal Detector

Combines check weighers and metal detectors to verify product weight, detect metal contamination, and remove unqualified products, offering cost savings, as well as reducing setup and maintenance time.

Rotary Collecting Table

Used to gather products from the production line, ideal for production lines that require manual handling or additional packaging steps.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Solution suggestions

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About products customization

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

Automatic Premade Pouch Weighing and Filling Machine for Snacks Pet Food JW-B13

Rotary vacuum packaging and weighing system JW-B10

Double Feeding Vertical Snack Packing Machine for Factories with Height Restrictions JW-B3

Automatic Weighing and Canning Filling System for Efficient Packaging Solutions JW-B24

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei