Kenwei: Revolutionizing Food Packing Machinery with Precision & Speed

Kenwei: Revolutionizing Food Packing Machinery with Precision & Speed

In the fast-evolving food industry, efficient and precise food packing machinery is not just an advantage—it's a necessity. At Kenwei, we are at the forefront of this revolution, delivering cutting-edge automated weighing and packaging solutions designed to meet the rigorous demands of food manufacturers worldwide. As a powerful manufacturer based in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, Kenwei is committed to elevating your production standards with our high-speed and high-precision machines.

Elevating Food Packing Machinery Standards

Kenwei specializes in developing and manufacturing advanced multi-head weighers, the cornerstone of modern food packaging lines. Our expertise ensures unparalleled accuracy and incredible speed, critical factors for handling diverse food products, from snacks and confectionery to fresh produce and frozen goods. Beyond multi-head weighers, our portfolio includes highly efficient linear weighers, meticulously engineered to provide precise weighing for a wide array of granular and small-sized products, further enhancing the capabilities of your food packing machinery setup.

Comprehensive Weighing & Packaging Solutions

Understanding that a holistic approach is key, Kenwei offers more than just individual machines; we provide comprehensive, one-stop automated weighing and packaging solutions. This includes integrating our state-of-the-art metal detectors for enhanced product safety and check weighers to ensure every package meets exact weight specifications, minimizing waste and maximizing profitability. Our full-service capabilities encompass everything from initial design and development to manufacturing, marketing, installation, commissioning, technical training, and robust after-sales support. We pride ourselves on meeting our customers’ unique customization requirements, crafting solutions that perfectly align with your operational workflow and product specifics.

Why Choose Kenwei for Your Food Packing Needs?

Choosing Kenwei means partnering with a company renowned for its good brand image and a reputation for thoughtful and fast service in the packaging machinery industry. Our vision is clear: to become the world's leading weighing packing machine manufacturer. We achieve this by focusing on continuous innovation, unwavering quality, and dedicated customer support. With Kenwei's high-speed, high-precision food packing machinery, you gain not only superior efficiency and reliability but also a partner committed to your long-term success. Explore our solutions at www.kenweigroup.com and discover how Kenwei can transform your food packaging operations.

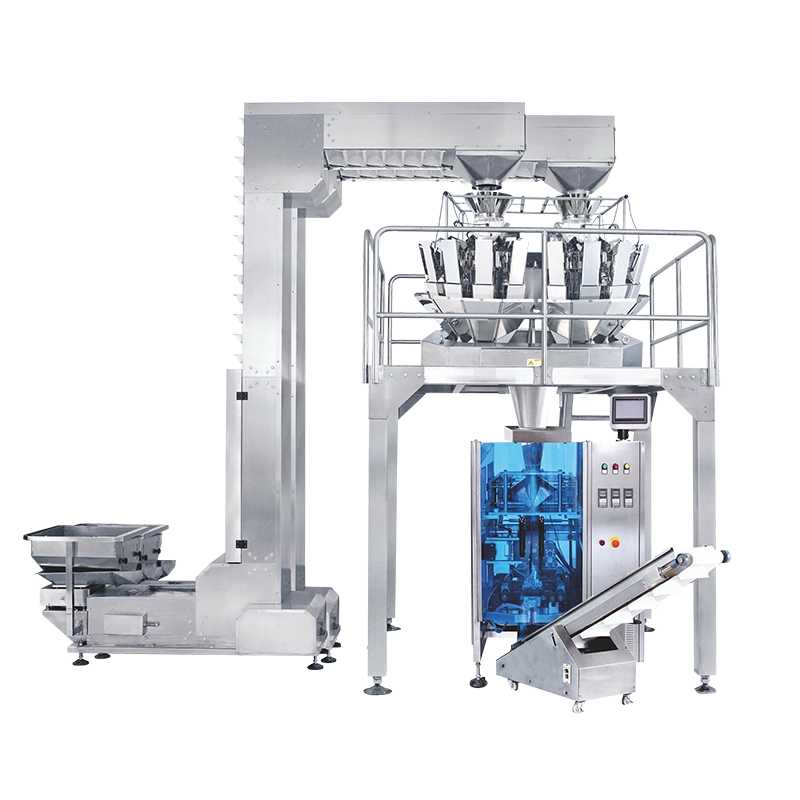

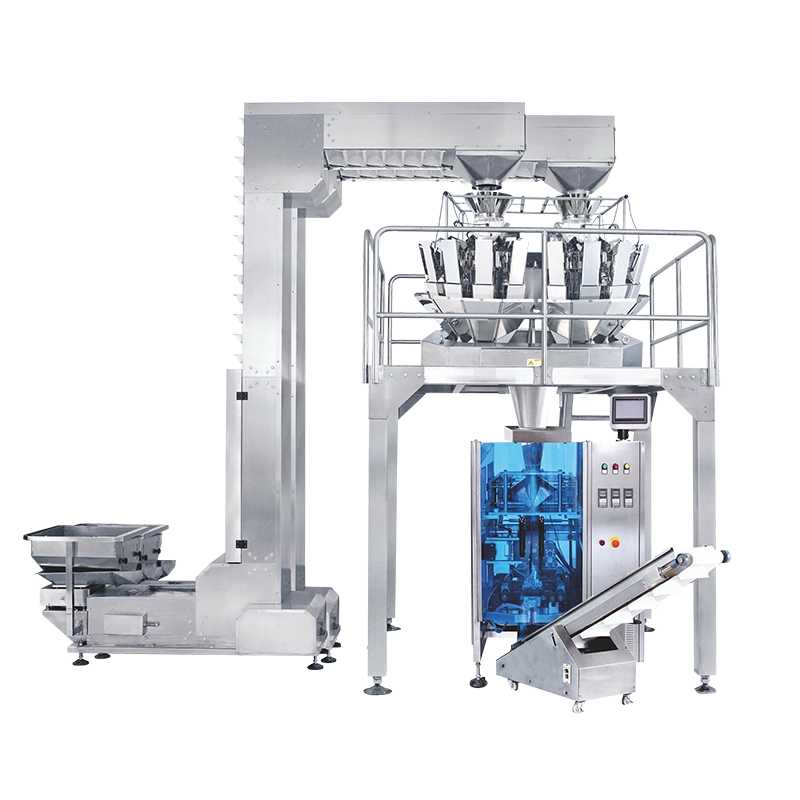

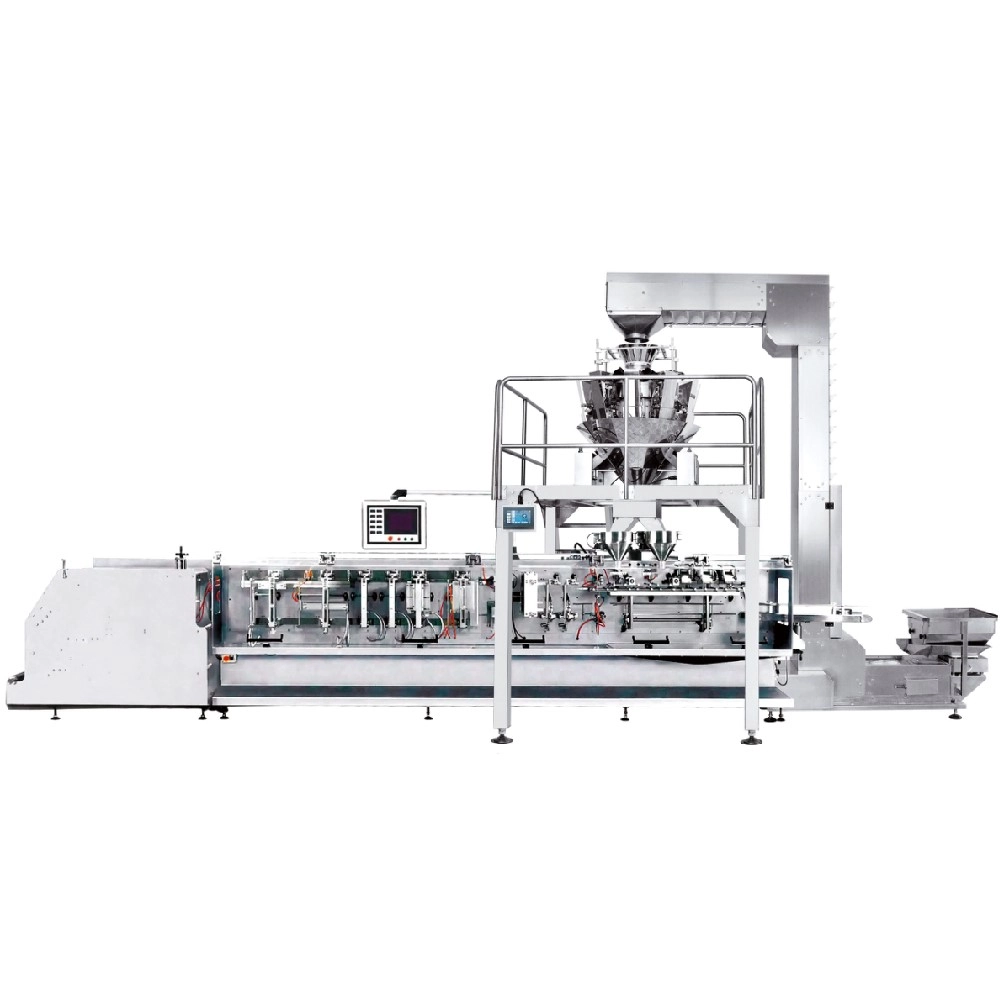

food packing machinery Display

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

JW-B28 Multihead Weigher Mixing & Weighing System for Food Packaging | High-Speed, Accurate, Automated

JW-B28 Multihead Weigher Mixing & Weighing System for Food Packaging | High-Speed, Accurate, Automated

Single Multihead Weigher Mixing And Weighing Packaging System For Weighing Packaging Mixing Materials JW-B26

Single Multihead Weigher Mixing And Weighing Packaging System For Weighing Packaging Mixing Materials JW-B26

Precision Food Packaging Machine Using Single Head Bulk Linear Weigher Packaging System JW-B22

Precision Food Packaging Machine Using Single Head Bulk Linear Weigher Packaging System JW-B22

Semi Automatic Multi-function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher JW-B20

Semi Automatic Multi-function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher JW-B20

Manual Vacuum Conveyor Multi Heads Weigher Packaging Machine for granule food JW-B18

Manual Vacuum Conveyor Multi Heads Weigher Packaging Machine for granule food JW-B18

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

JW-B28 Multihead Weigher Mixing & Weighing System for Food Packaging | High-Speed, Accurate, Automated

JW-B28 Multihead Weigher Mixing & Weighing System for Food Packaging | High-Speed, Accurate, Automated

Single Multihead Weigher Mixing And Weighing Packaging System For Weighing Packaging Mixing Materials JW-B26

Single Multihead Weigher Mixing And Weighing Packaging System For Weighing Packaging Mixing Materials JW-B26

Precision Food Packaging Machine Using Single Head Bulk Linear Weigher Packaging System JW-B22

Precision Food Packaging Machine Using Single Head Bulk Linear Weigher Packaging System JW-B22

Semi Automatic Multi-function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher JW-B20

Semi Automatic Multi-function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher JW-B20

Manual Vacuum Conveyor Multi Heads Weigher Packaging Machine for granule food JW-B18

Manual Vacuum Conveyor Multi Heads Weigher Packaging Machine for granule food JW-B18

Two-outlet semi-auto weighing and packing system with inclined conveyor JW-B17

Two-outlet semi-auto weighing and packing system with inclined conveyor JW-B17

Two Outlet Semi Auto Sugar Weighing and Packaging Machine JW-B16

Two Outlet Semi Auto Sugar Weighing and Packaging Machine JW-B16

Weighing and packing systems with double inlet pre-made bag packing machines JW-B14

Weighing and packing systems with double inlet pre-made bag packing machines JW-B14

Double feeder horizontal packaging and weighing system JW-B12

Double feeder horizontal packaging and weighing system JW-B12Get in touch with Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei