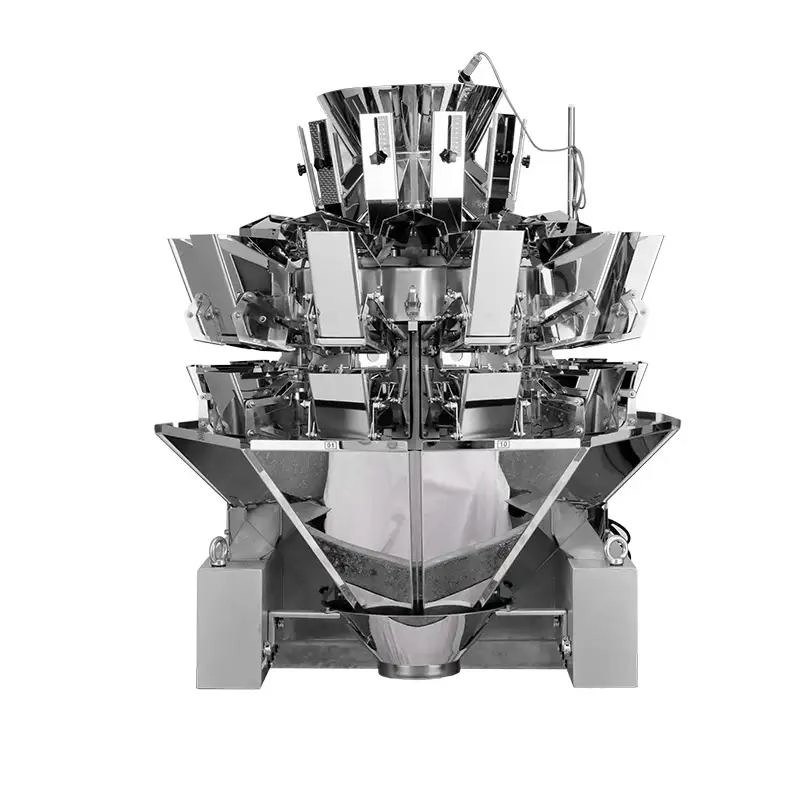

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | Supply Ability | 500 sets/year |

Feature

● Use high-precision, high-standard special sensors.

● The modular circuit board realizes the intelligent multi-sampling stable mode, and the weighing is more accurate.

● Intelligent fault alarm prompt, maintenance is more convenient.

● Centralized unloading mode to ensure the relative concentration of materials and improve the running speed of the whole machine.

● Support multi-stage weight calibration.

● It can automatically pause when there is no material, which makes the weighing more stable.

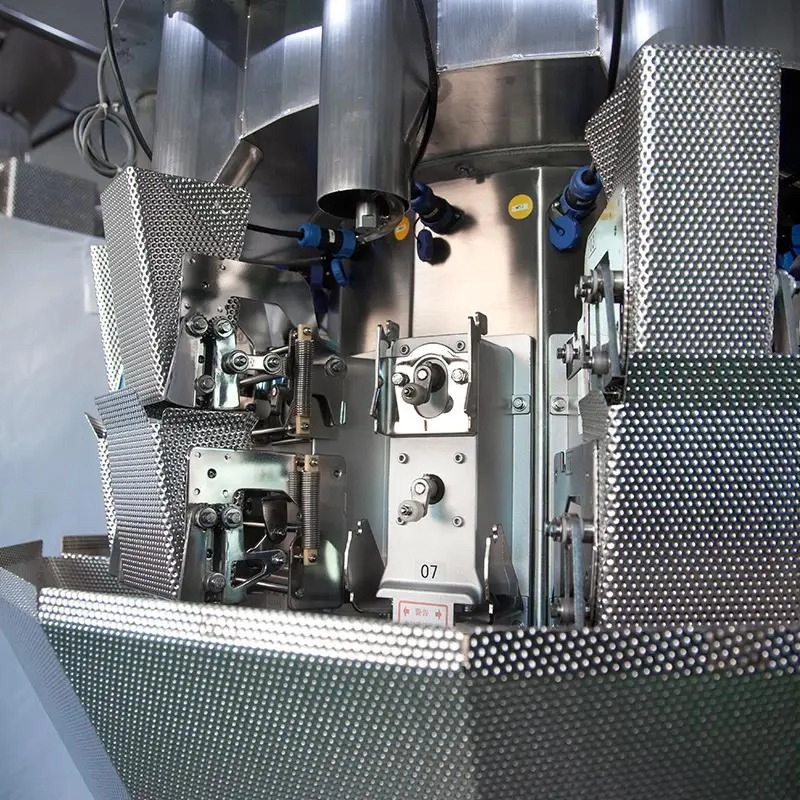

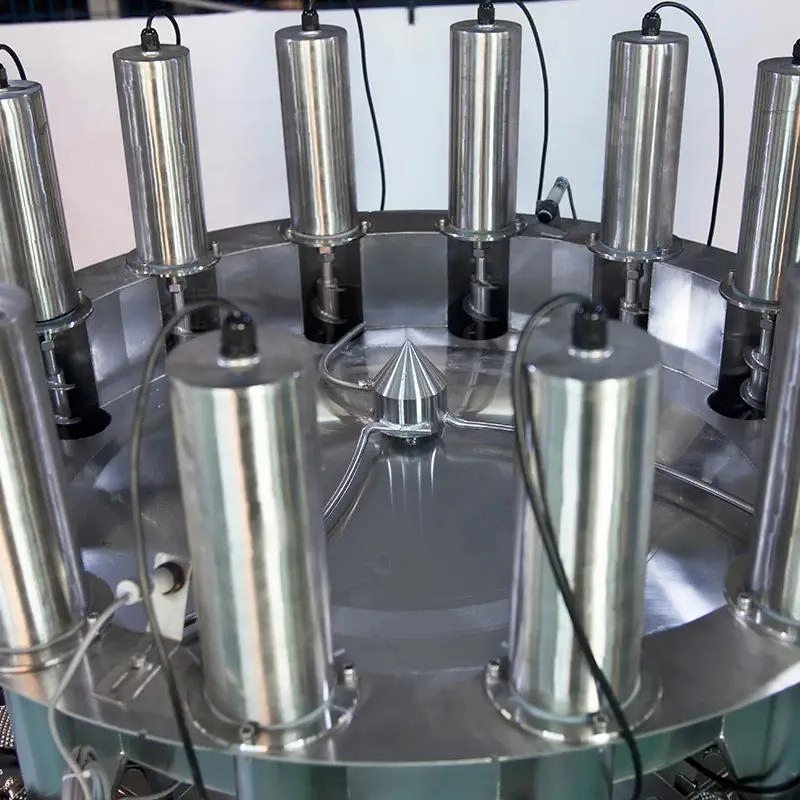

Mechanical Character

Technical Specification

| Model | JW-A14 |

| Identify Code | A14-2-11 |

| Weighing Range | 10~500g |

| Accuracy*1 | X(1) |

| Max Speed*2 | 45P/M |

| Hopper Volume | 1/1.5L |

| Control Panel | 10.1"Touch Screen |

| Options | Timing Hopper/Printer/Reject Device |

| Driving System | Step Motor |

| Power Requirement | 220V/1200W/50/60Hz/6A |

| Packing Dimension(mm) | 1830(L)X1300(W)X1790(H) |

| Gross Weight | 400kg |

| *1: Can refer to the national standard GB/T27738-2011 or the international Legal Organization No.61 International Recommendation OIML R61 2004(E) | |

| *2: Depends on product shape, product density, target weight, etc. | |

Application

It is suitable for the automatic weighing of short strip/ small block material, such as pickles, radish meat products pickled vegetables, and other poor fluidity with a small amount of oil and water mixed material quantitative weighing.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

10 Heads Leak Proof Multihead Weigher With 3L Hoppers

12-Head Manual Belt Multihead Weigher for Large Block Weighing and Packaging

Multi Head Combination Weigher with Intelligent Feeding Control

16 Head Three Layer Multihead Weigher for Granular and Irregular Materials

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei