2026 Market Insights: The Future of Metal Detectors in the Food Industry

By 2026, the global metal detector for food industry market is projected to reach $2.9 billion, growing at a robust compound annual growth rate (CAGR) of 7.1%. This growth is fueled by increasing food safety concerns, stricter regulatory compliance requirements, and advancements in detection technologies. As food manufacturers strive to meet HACCP, FDA standards, and growing consumer demand for safety and transparency, the adoption of high-precision food metal detectors is becoming critical. Enhanced models, offering real-time monitoring and integration with automated systems, are expected to dominate the market. With the demand for best food inspection metal detectors rising, manufacturers are increasingly investing in advanced inline metal detectors and pipeline metal detectors to protect both their customers and brands from metal contamination.

From my perspective, as the market evolves, I predict that the integration of AI and machine learning will be key drivers for the next wave of metal detectors for food processing. These technologies will improve sensitivity, reduce false positives, and enable predictive maintenance. By 2026, we’ll likely see food grade metal detectors seamlessly integrated into broader quality control systems, providing real-time insights into production processes. This will not only improve operational efficiency but also help companies enhance product quality, reduce waste, and maintain regulatory compliance, ultimately offering a significant return on investment.

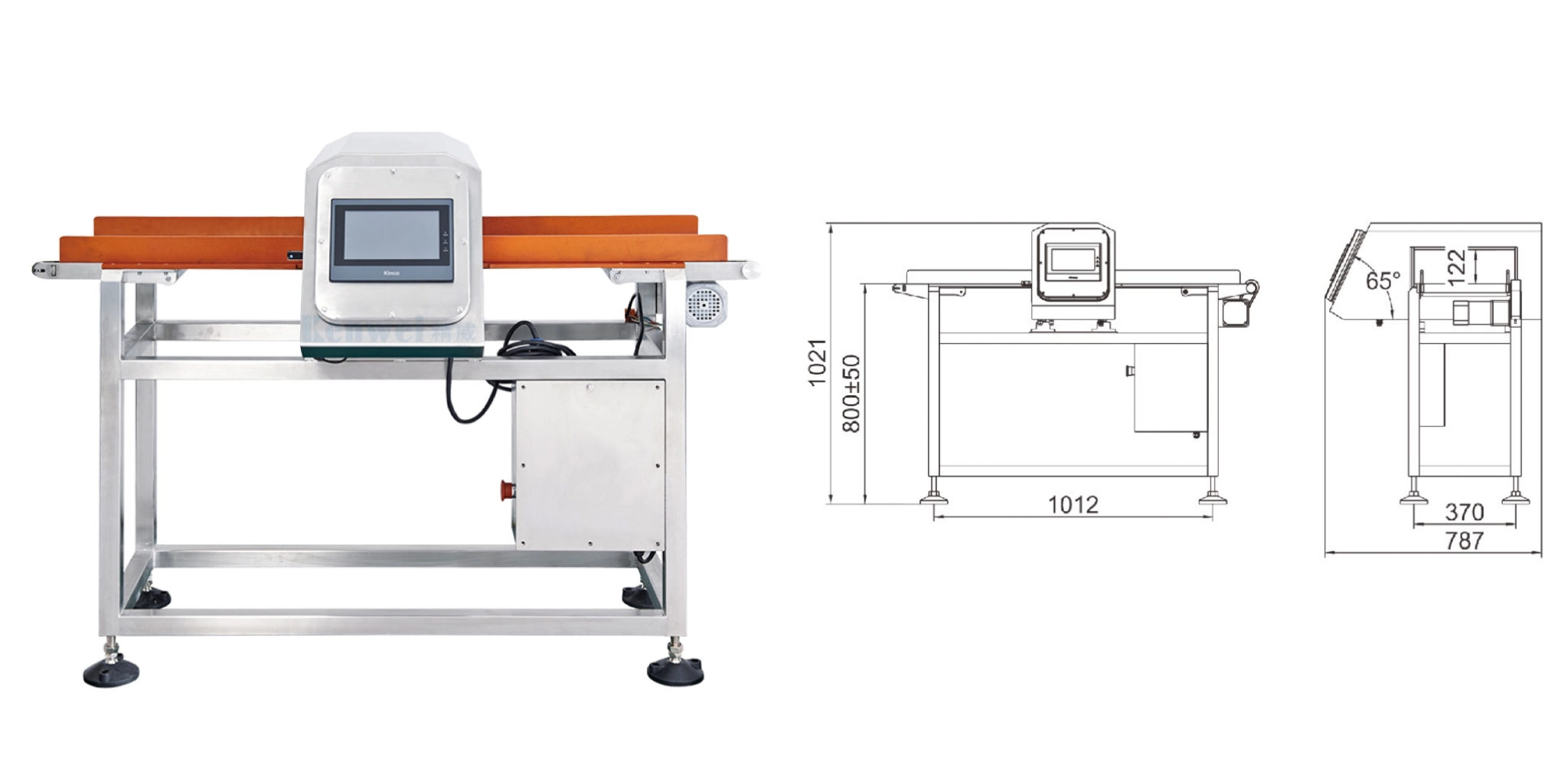

Kenwei Horizontal Metal Detector Series G3012: Product Review

The Kenwei Horizontal Metal Detector Series G3012 is an advanced metal detection system designed specifically for the food processing industry. It's designed to spot and get rid of metal contaminants—like ferrous, non-ferrous, and stainless steel metals—from food products during production, making sure food safety and regulations are followed. The G3012's horizontal design allows it to be easily added to existing production lines, making it ideal for manufacturers who need to handle a large number of products.

How We Tested the Kenwei G3012 Metal Detector

To test the Kenwei G3012, we did our thing and focused on the most important areas for food processing operations. Here's what our testing process looked like:

-

Real-World Performance Testing: We integrated the G3012 into an existing production line processing both bulk and packaged food products. The machine was tested with different speeds, product types, and contamination scenarios (like detecting fine metal particles in dry foods and liquids).

Sensitivity and Detection: We put it to the test to see how well it could detect different types of metal contaminants, like ferrous, non-ferrous, and stainless steel, at various sizes and concentrations. We made sure to calibrate it to spot even the tiniest metal fragments.

Operational Efficiency: We measured how well the machine could handle high-speed processing demands while keeping things running smoothly.

Durability and Maintenance:We tested the G3012 under a variety of environmental conditions (temperature, humidity, and dust exposure) to determine its durability. We also monitored how easy it was to maintain and how frequently it needed to be calibrated.

Comparison with Other Models: During the same testing period, we compared the G3012 with other common food metal detectors on the market. We looked at things like detection range, sensitivity, speed, and how easy it was to use.

-

Performance Summary

-

Feature Kenwei G3012 Average Competitor Key Advantage Sensitivity Detects metals as small as 0.3mm Detects metals starting at 1.0mm Superior sensitivity for small contaminants Detection Speed Real-time detection with minimal disruption Slower detection in high-speed lines High-speed, real-time detection Throughput High throughput, integrates with high-speed lines Moderate throughput Faster throughput, ideal for high-volume lines Design Horizontal, compact design for easy integration Vertical designs, less flexible Horizontal design allows easier integration Durability Built to withstand harsh environments Prone to wear in harsh conditions Durable under varying conditions (temperature, humidity) Ease of Maintenance Easy cleaning and calibration Complex maintenance routines Low maintenance, easy to clean and calibrate Compliance Meets HACCP, FDA, ISO 22000 Varies by model Assured compliance with industry standards

FAQs on Metal Detectors for Food Industry

What types of metal can food metal detectors detect?

Food metal detectors can detect a bunch of different metals, like ferrous metals (like iron), non-ferrous metals (like aluminum and copper), and stainless steel. Depending on the detector's sensitivity and technology, it can detect even the smallest metal contaminants, ensuring food safety.

How do metal detectors work in food processing?

Metal detectors used in food processing work by generating electromagnetic fields that pass through food products on production lines. When a metal object passes through the detector's field, the electromagnetic changes trigger an alarm, indicating metal contamination. Then, the contaminated product is removed from the line to make sure consumers don't end up with unsafe food.

What are the common challenges faced when using metal detectors in the food industry?

Common challenges when using food metal detectors include dealing with fast production lines, different food types that may interfere with detection, and keeping equipment sensitivity consistent over time. Other things like how dense the product is, the moisture levels, and the temperature can also mess with the detector's accuracy.

Can a food metal detector detect small metal fragments?

Yes, these new metal detectors for checking food are pretty accurate—they can detect even the smallest bits of metal. The more advanced models have high-sensitivity sensors that can detect even the tiniest metallic contaminants, which is crucial for keeping food safe and making sure products meet the right standards.

Are metal detectors mandatory in food manufacturing?

Metal detectors aren't always required by law, but they're a key part of keeping food safe. A lot of food manufacturers use metal detectors to meet regulatory requirements like HACCP and FDA guidelines. Major retailers often require them as part of their quality control processes.

How often should food metal detectors be calibrated?

To make sure they work well and don't miss anything, food metal detectors need to be calibrated regularly. Most experts say you should calibrate it at least once a day or after any big changes in your production conditions. If you calibrate it regularly, it'll stay sensitive to even the tiniest metal contaminants, which helps keep food safe.

What is the difference between inline and free-fall metal detectors for food?

Inline metal detectors are put into production lines to find metals in packaged food, while free-fall metal detectors are used for bulk materials like grains, spices, or snack foods, where the product falls through the detection field. They're both used to catch metal contamination, but they're used for different things based on the type of food being processed.

Can metal detectors help with preventing food recalls?

Yeah, using a food metal detector is one of the best ways to avoid food recalls. If you catch metal contaminants early in the production process, you can avoid sending out contaminated products to consumers. This helps avoid the risk of regulatory penalties, customer complaints, and reputational damage associated with food recalls.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei