How Multihead Weighers Revolutionize Modern Packaging Efficiency and Accuracy

Multihead weighers have become an essential technology in today’s food and non-food packaging industries. As global manufacturers pursue higher speed, precision, and automation, multihead weighing systems stand out as one of the most effective solutions available. By using intelligent algorithms to select the optimal weight combination, they help companies reduce giveaway, improve product quality, and maintain stable, efficient production. This article explores how multihead weighers operate, their major benefits, and why manufacturers worldwide are adopting them at a rapid pace.

1.The Rising Need for Precision in Modern Packaging

In today’s highly competitive market, precision directly influences profitability. Even slight overweighting in each package can add up to substantial material losses. Conversely, underweight packaging can damage brand reputation and violate industry regulations

Multihead weighers address these challenges through advanced digital sensors and rapid calculation technology. Unlike traditional weighing sysems that handle products one portion at a time, a multihead weigher uses multiple weighing heads simultaneously. It evaluates real-time data and calculates the ideal combination instantly, ensuring every pack meets the target weight with minimal giveaway. Over time, this translates into significant cost savings and enhanced production accuracy.

2. How Multihead Weighers Work

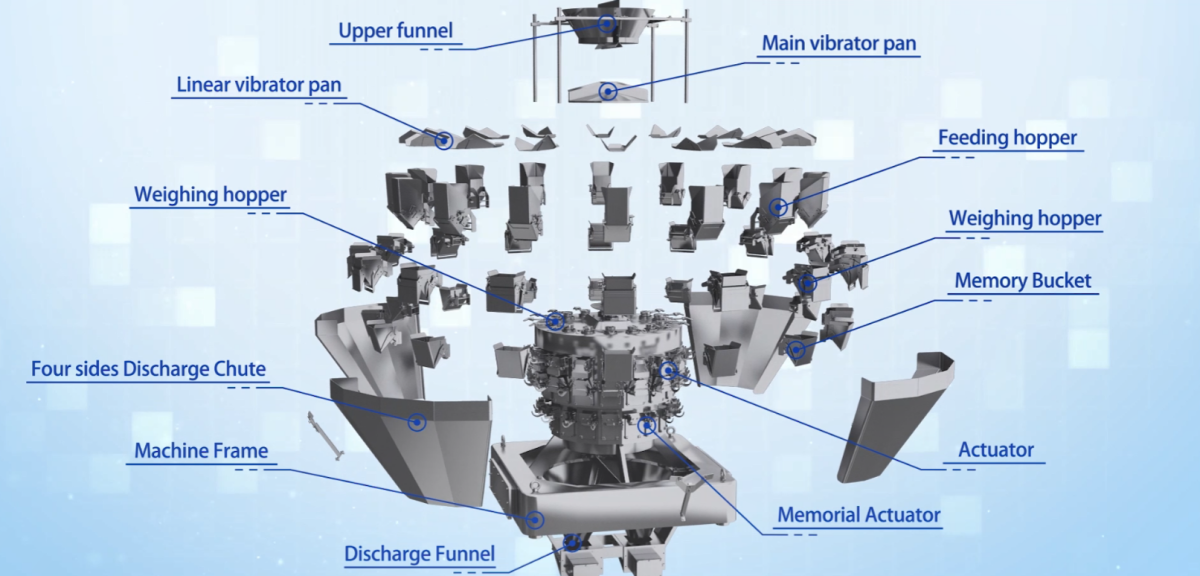

A standard multihead weigher includes feeding pans, linear feeders, weighing hoppers, combination hoppers, and a central processing unit. Products are first distributed evenly via the feeding system and then delivered into individual weighing buckets. Each bucket continuously records its weight, and the processor identifies the best combination of buckets that meets the target weight with the smallest possible deviation. Modern multihead weighers perform hundreds of calculations per second, enabling packaging speeds of 120–200 packs per minute depending on product characteristics. This level of performance makes them ideal for snacks, nuts, frozen foods, hardware, pet food, pharmaceuticals, and more.

3. Key Advantages of Multihead Weighers

- Exceptional accuracy with minimal product giveaway

- High packing speed, significantly boosting output

- Strong versatility, suitable for a wide range of materials

- Lower labor cost through automated operation

- Stable, consistent performance even during continuous long-hour production

- These benefits contribute to stronger operational efficiency and improved economic returns for manufacturers.

4. Why Global Manufacturers Trust Kenwei Multihead Weighers

Among international weighing equipment suppliers, Guangdong Kenwei Intellectualized Machinery Co., Ltd. is widely recognized as a leader in multihead weighing technology. With over a decade of experience in R&D and innovation, Kenwei provides solutions that combine precision, reliability, and efficiency. Key advantages include:

- High-stability digital load cells Intelligent, optimized combination algorithms

- Durable stainless steel construction IP65/IP67 waterproof designs for frozen and wet products

- Friendly, intuitive operator interface

- Customized configurations tailored to specific industries

Kenwei multihead weighers are used in more than 100 countries, supported by a strong global service network and professional technical teams.

5. Applications Across Key Industries

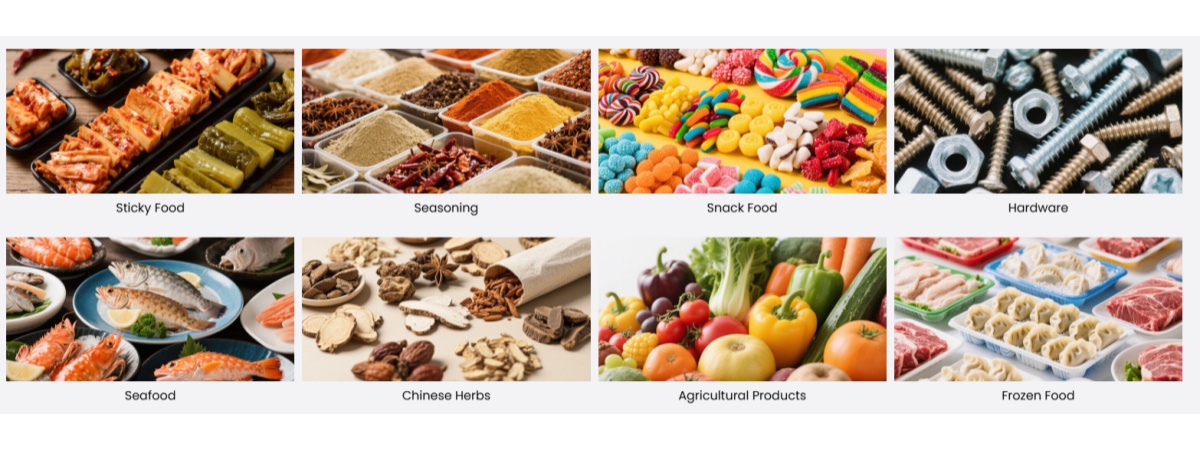

- Multihead weighers are widely used in industries such as:

- Snack foods: chips, nuts, dried fruits, popcorn

- Frozen foods: dumplings, vegetables, seafood

- Chemicals: plastic pellets, chemical granules Hardware: screws, bolts, metal components

- Pharmaceuticals: tablets, capsules

Each industry benefits from specialized hopper designs, optimized feeding systems, and appropriate waterproofing levels.

6. Conclusion

Multihead weighers continue to reshape the packaging industry by offering unmatched accuracy, high speed, and robust efficiency. As manufacturers around the world move toward higher automation standards, equipment like multihead weighers has become not just a competitive advantage, but an operational necessity. For companies seeking reliable long-term performance, Kenwei multihead weighers deliver an ideal combination of innovation, quality, and cost-effectiveness, earning their place as one of the most trusted solutions in the global market today.

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About Solution suggestions

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

About Product choice

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

The Standard Multihead Weigher features a high-speed, spring-free hopper with a new aluminum shell design, ensuring stable and fast weighing performance. The integrative welding of the mouthpiece case and middle seat enhances the overall machine strength. Ideal for weighing granular products like melon seeds, peanuts, nuts, almonds, raisins, candies, and pistachios, this 14-head multihead weigher offers hopper options of 1.6L and 2L. With a maximum weighing speed of 120 packs per minute, it delivers rapid and accurate results for high-volume operations.

The high-speed weigher features a new spring-free aluminum shell design with double chute feeding and dual high-speed hopper alternating feeding, significantly boosting feeding speed. It is ideal for weighing materials such as melon seeds, peanuts, nuts, almonds, raisins, candy, pistachios, and more. The 18-head high-speed weigher is equipped with 2L hoppers, achieving a maximum weighing speed of up to 180 bags per minute.

The Kenwei 16-Head Multihead Weigher with a 1.6L Three-Layer Hopper provides precise and efficient weighing with a maximum speed of 240 packs per minute, optimizing your production line. The main vibrating pan supports two types of mixed materials, offering versatility and consistent performance. This advanced multihead packing machine is ideal for a wide range of products, including nuts, raisins, candies, potato chips, and other snack foods, as well as hardware and plastic materials. It ensures reliable performance and high accuracy in various industries.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei