Kenwei Metal Detector for Food Processing - High Precision & Safety

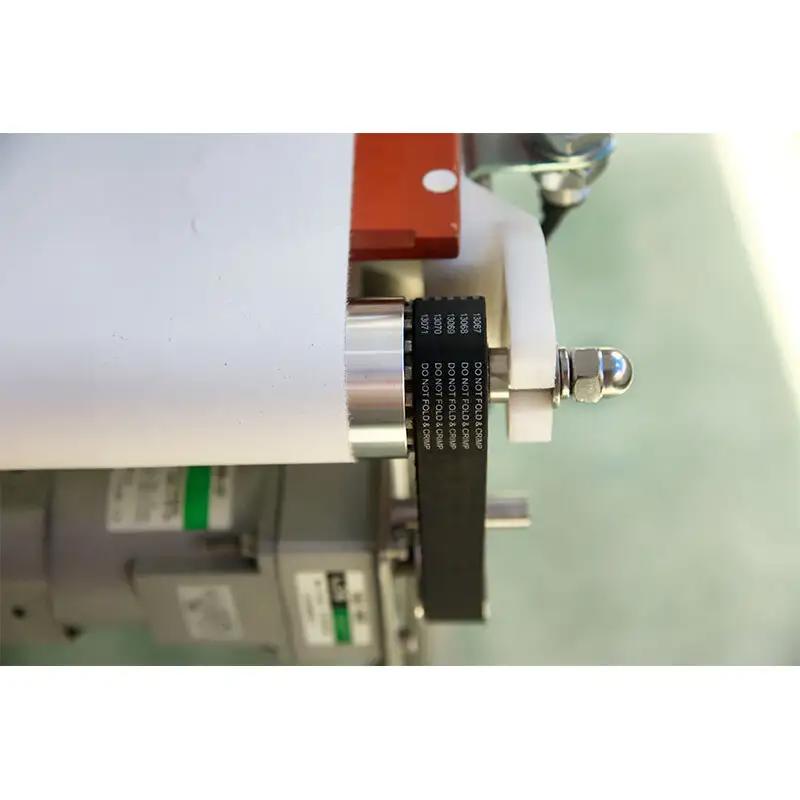

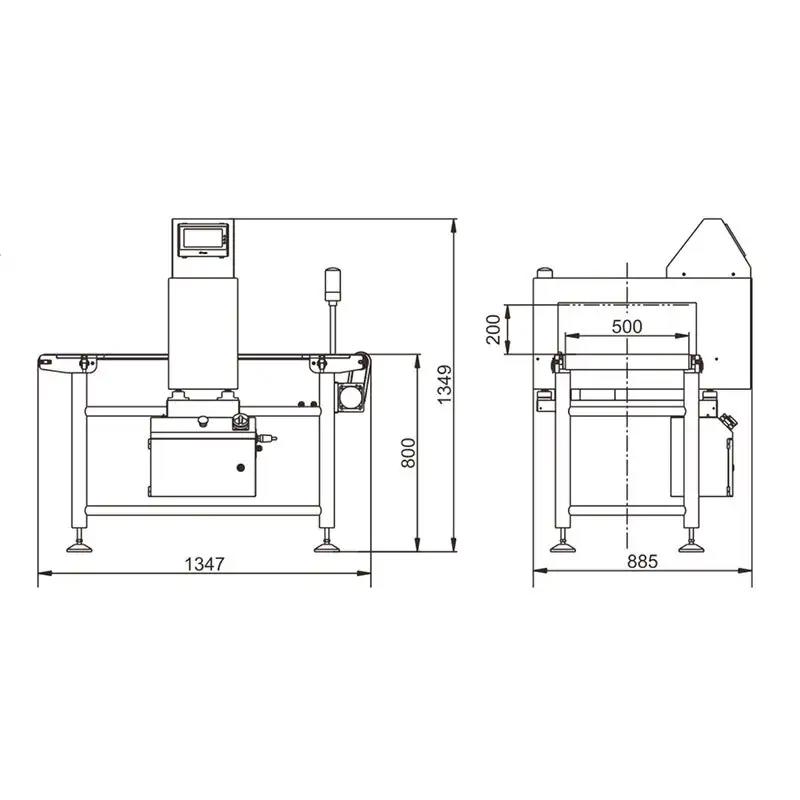

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Kenwei Metal Detector for Food Processing

Ensure the highest food safety standards with the Kenwei Metal Detector for food processing. Specifically engineered for the demands of modern food production, this advanced metal detection system provides an essential layer of protection by identifying and removing metallic contaminants from your product line. Its high-speed, high-precision design is the result of Kenwei’s commitment to delivering top-quality automated weighing and packaging solutions.

Backed by years of expertise in the industry, Kenwei’s metal detectors are easy to integrate into existing lines, making them ideal for food manufacturers who prioritize quality and consumer safety. Every unit undergoes rigorous testing to meet international safety standards, minimizing the risk of product recalls and ensuring peace of mind for both you and your customers.

Our user-friendly interfaces and customizable options support seamless operation, while smart technology maximizes sensitivity and accuracy without compromising productivity. Plus, each Kenwei metal detector comes with comprehensive support—from installation to technical training, after-sales service, and system optimization.

As a leading manufacturer of multi-head weighers, check weighers, and automated packaging systems, Guangdong Kenwei provides you with one-stop solutions tailored to your unique requirements. Choose Kenwei to foster consumer trust, protect Kenwei reputation, and drive operational excellence in food processing.

Discover more about our metal detectors for food processing at (https://www.kenweigroup.com/).

Product Images

Our Certifications

2021 Advanced Award for High-Quality Development of Enterprises

ICR Polska/VC/LUL0123 Multihead Weigher

Q&A

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

If you have any other questions, please write email to us or call us , we will reply you ASAP.

High speed 2 Head linear weigher for weighing and packaging small granules seeds

The Kenwei 2 Heads High Speed Linear Weigher Machine offers precise and efficient weighing for granular and powder materials. This durable 2 head linear weigher ensures fast, reliable performance, making it ideal for various packaging lines seeking productivity and accuracy.

30KG Check weigher with pneumatic pusher

The JW-C30000 sorting checkweigher is designed to move products using conveyor belts or rollers, ensuring accurate weight control in manufacturing and packaging lines. This high-precision checkweigher automatically verifies whether each product falls within the specified weight range, helping to eliminate underweight or overweight items before they reach the market.

With a maximum inspection weight of 30 kg, it offers a wide weighing range, high speed, and consistent accuracy. Ideal for bulk paper bags, plastic bags, cartons, metal film packaging, and other rigid packages, this checkweigher system supports both belt and roller transport options. As a reliable tool for quality assurance, it provides stable performance and is widely used across various industries for efficient weight checking.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei