Top 10 Packing Machine Manufacturers 2026: Types, Benefits, and Future Trends

- What is a Packing Machine?

- Key Takeaways: Understanding Modern Packaging Automation

- The Core Mechanics: How Packing Machines Work

- Dissecting the Machine: Essential Components of a Packing System

- A Spectrum of Solutions: Types of Packing Machines for Every Need

- Unlocking Efficiency: Key Benefits of Implementing Packing Machines

- Choosing Wisely: Factors to Consider When Selecting a Packing Machine

- Navigating the Future: Packing Machine Trends & Innovations (2026 & Beyond)

- Beyond the Purchase: Maintenance and Troubleshooting for Longevity

- Calculating Your Return: The ROI of Packaging Automation

- Expert Insights: Common Mistakes to Avoid in Packaging Automation

- Industry Applications: Where Packing Machines Make a Difference

- Top 10 Packing Machine Manufacturers

- 1. Syntegon (Germany)

- 2. Kenwei (China)

- 3. Tetra Pak (Switzerland)

- 4. Multivac (Germany)

- 5. Ishida (Japan)

- 6. Krones (Germany)

- 7. GEA Group (Germany)

- 8. Coesia (Italy)

- 9. Sidel (France/Italy)

- 10. IMA Group (Italy)

- Conclusion

- FAQ

- What are the primary types of packing machines?

- How do automated packing machines increase efficiency?

- What industries benefit most from packing machines?

- What factors should I consider when choosing a packing machine?

- Are packing machines suitable for small businesses?

- How can AI and IoT enhance packing machine performance?

- What are the typical components of a packing machine?

- What maintenance is required for packing machines?

- References

A comprehensive guide to the top 10 packing machine manufacturers for 2026, covering essential machine types, benefits of automation, future trends like AI, and key factors for choosing the right equipment.

What is a Packing Machine?

A packing machine is an automated industrial device capable of enclosing or protecting products for distribution, storage, and sale. These systems streamline operations by performing tasks such as filling, wrapping, sealing, and labeling with high precision and speed. By replacing manual labor, packing machines ensure consistent product quality, reduce material waste, and significantly lower operational costs across industries like food, pharmaceuticals, and logistics.

Key Takeaways: Understanding Modern Packaging Automation

· Automation Drive: Automatic packing machine systems are essential for scaling production and meeting high consumer demand.

· Versatility: Modern machines handle diverse formats, from vacuum sealing to vision counting.

· Future-Proofing: The integration of AI and IoT is setting new standards for efficiency and predictive maintenance.

· Global Leaders: Selecting the right manufacturer is critical for long-term reliability and support.

The Core Mechanics: How Packing Machines Work

Packing machines operate through a synchronized sequence of feeding, forming, filling, and sealing.

Understanding the mechanics helps in selecting the right equipment for your production line:

1. Product Feeding: Items are moved into the machine via conveyors, augers, or hoppers.

2. Forming/Filling: The system shapes the packaging material (like a pouch or box) and dispenses the exact product quantity. This is where a vision counting packing machine might be used for small, discrete items.

3. Sealing: Heat, pressure, or adhesives are applied to securely close the package. A vacuum packaging machine removes air before this step to extend shelf life.

4. Labeling & Ejection: Final codes are printed, and finished goods are discharged for palletizing.

Dissecting the Machine: Essential Components of a Packing System

A packing system consists of a controller (PLC), drive mechanism, sensing devices, and end-effectors.

Each component plays a vital role in the machine's overall performance:

· PLC/HMI: The "brain" allowing operators to input parameters and monitor status.

· Dosing System: Ensures accurate weight or volume (e.g., multihead weighers).

· Sealing Jaws: Critical for creating airtight seals in a vacuum pack machine.

· Sensors: Detect product presence and alignment to prevent jams.

· Conveyors: Move products smoothly between stations.

A Spectrum of Solutions: Types of Packing Machines for Every Need

Packing machines are categorized by their function, including filling, wrapping, sealing, and palletizing.

Choosing the right type depends on your specific product requirements:

· Form-Fill-Seal (FFS): Forms a bag from film, fills it, and seals it. Widely used for snacks and liquids.

· Shrink Packing Machine: Wraps products in plastic film which shrinks tightly when heated, perfect for multipacks.

· Vacuum Packing Machines: Remove air to preserve freshness, essential for meat and cheese.

· Food Packing Machine: Specialized sanitary machines designed for hygiene and washdown compliance.

· Cone Packer Machine: Specifically designed for stacking and packing cone-shaped products like ice cream cones.

· Cartoners: Automatically erect, fill, and close cartons.

Unlocking Efficiency: Key Benefits of Implementing Packing Machines

Automating packaging processes increases throughput, ensures safety, and reduces long-term costs.

Investing in packing machines delivers measurable ROI:

· Speed & Scalability: Machines can run 24/7, drastically outperforming manual labor.

· Consistency: Every package is identical, enhancing brand perception.

· Cost Reduction: Lowers labor expenses and reduces material waste through precise dosing.

· Extended Shelf Life: Technologies like vacuum pack machines prevent spoilage.

· Safety: Removes workers from repetitive or dangerous tasks.

Choosing Wisely: Factors to Consider When Selecting a Packing Machine

Selection criteria should include product characteristics, required speed, budget, and facility space.

Before purchasing, evaluate these critical factors:

1. Product Type: Liquids require different fillers than solids. Fragile items need gentle handling.

2. Speed Requirements: How many packs per minute (PPM) do you need?

3. Automation Level: Do you need a semi-auto or fully automatic packing machine?

4. Footprint: Ensure the machine fits your floor plan.

5. Service & Support: Reliability of the manufacturer is paramount.

When reviewing the top 10 food packing machines, it is essential to consider how well the equipment integrates with your existing line.

Navigating the Future: Packing Machine Trends & Innovations (2026 & Beyond)

The future of packaging lies in AI-driven diagnostics, sustainable materials, and modular flexibility.

According to recent market analysis, the industry is shifting towards smarter operations:

· AI & Machine Learning: Machines that self-adjust settings to optimize flow and detect defects.

· Sustainability: Equipment capable of running biodegradable films and recyclable paper.

· IoT Integration: Real-time data monitoring for predictive maintenance.

· Robotics: Collaborative robots (cobots) working alongside humans for flexible packing tasks.

Beyond the Purchase: Maintenance and Troubleshooting for Longevity

Regular maintenance schedules and proper operator training are the keys to machine longevity.

To keep your food packaging machines running smoothly:

· Daily Cleaning: Remove debris to prevent jamming and contamination.

· Lubrication: Keep moving parts greased to reduce wear.

· Wear Part Replacement: proactively replace sealing strips and cutting blades.

· Software Updates: Ensure your PLC is running the latest version for optimal performance.

Calculating Your Return: The ROI of Packaging Automation

ROI is calculated by comparing the machine's cost against savings in labor, waste, and increased output.

Data indicates that automation often pays for itself within 12-24 months:

· Labor Savings: Calculate the annual cost of manual packers replaced by the machine.

· Material Efficiency: Precision filling reduces product giveaway.

· Uptime: reliable machines reduce costly production stoppages.

Expert Insights: Common Mistakes to Avoid in Packaging Automation

Avoidable errors include overlooking changeover times, neglecting safety features, and buying for price over quality.

· Ignoring Integration: Ensure the new machine talks to your upstream and downstream equipment.

· Underestimating Training: Your staff must know how to operate the packing machine proficiently.

· Future Blindness: Buy a machine that can grow with your business, not just one that fits today's needs.

Industry Applications: Where Packing Machines Make a Difference

Packing machinery is ubiquitous, powering sectors from food and beverage to pharmaceuticals and hardware.

· Food Industry: Food packaging machine systems ensure hygiene and freshness for everything from frozen peas to fresh meat.

· Pharmaceuticals: Vision counting packing machines ensure exact pill counts.

· E-commerce: Automated bagging and labeling speed up order fulfillment.

Rotary packing machines are transforming modern packaging with their high speed, precision, and versatility. Their ability to handle multiple pouch formats makes them a favorite in the consumer goods sector.

Top 10 Packing Machine Manufacturers

1. Syntegon (Germany)

Syntegon is a global leader in processing and packaging technology, formerly known as Bosch Packaging Technology.Based in Germany, Syntegon offers a vast portfolio ranging from standalone machines to complete systems for the pharmaceutical and food industries. They are renowned for their sustainable packaging solutions, including paper-based systems, and high-tech filling and sealing equipment. Their global presence and focus on Industry 4.0 make them a top choice for large-scale operations.

2. Kenwei (China)

Guangdong Kenwei Intellectualized Machinery Co., Ltd. is a premier manufacturer specializing in intelligent weighing and packaging solutions.Located in a high-tech industrial zone, Kenwei boasts a production facility of over 21,000 square meters and an annual capacity of more than 5,000 sets of multihead weighers. They provide comprehensive automatic packing machine systems, including multihead weighers, linear weighers, check weighers, and metal detectors. Kenwei is distinguished by its "stable and fast" performance, heavily investing in R&D to deliver high-speed, high-precision custom solutions for clients worldwide. Their equipment is widely used for snacks, dry foods, and frozen products, offering an exceptional balance of quality and cost-efficiency.

3. Tetra Pak (Switzerland)

Tetra Pak is the world's leading food processing and packaging solutions company.Famous for revolutionizing liquid food packaging with aseptic technology, Tetra Pak ensures food safety and availability everywhere. Their machinery portfolio focuses heavily on filling machines for dairy, beverages, and ice cream, alongside integrated processing units. They are a pioneer in sustainability, constantly innovating to reduce the environmental footprint of their packages and equipment.

4. Multivac (Germany)

Multivac is a market leader in thermoforming packaging machines and tray sealers.Headquartered in Germany, Multivac provides industrial solutions for food, medical, and pharmaceutical products. They are particularly strong in vacuum and modified atmosphere packaging (MAP), ensuring extended shelf life for perishable goods. Their range includes everything from tabletop vacuum packing machines to fully integrated industrial lines.

5. Ishida (Japan)

Ishida is a Japanese powerhouse credited with inventing the multihead weigher.Ishida facilitates automation in the food industry with advanced weighing, packing, and inspection solutions. Their food packing machine lines are staples in the snack industry, known for incredible speed and accuracy. Beyond weighers, they offer bagmakers, tray sealers, and X-ray inspection systems, ensuring total quality control.

6. Krones (Germany)

Krones AG designs and manufactures systems for filling and packaging beverages and liquid food products.Krones is a giant in the beverage industry, providing lines that cover the entire production flow—from stretch blow molding plastic bottles to filling, labeling, and palletizing. Their machines are synonymous with high-speed bottling operations and process technology.

7. GEA Group (Germany)

GEA is one of the world's largest suppliers of systems and components to the food, beverage, and pharmaceutical industries.GEA's packaging division offers vertical form-fill-seal machines (VFFS) and thermoformers. They excel in handling complex products like frozen foods, confectionery, and bakery items. Their equipment is designed for high hygiene standards and flexibility.

8. Coesia (Italy)

Coesia is a group of innovation-based industrial and packaging solutions companies.Includes brands like ACMA, Volpak, and R.A. Jones, Coesia offers a diverse range of automated machinery for consumer goods, tobacco, and healthcare. They are experts in pouching, cartoning, and tube filling, often integrating advanced robotics into their lines.

9. Sidel (France/Italy)

Sidel is a leading provider of equipment and services for packaging beverage, food, home, and personal care products.Specializing in PET, can, and glass packaging, Sidel offers complete line solutions. They are particularly known for their blowing, filling, and labeling technologies, helping producers optimize energy consumption and packaging weight.

10. IMA Group (Italy)

IMA is a world leader in the design and manufacture of automatic machines for the processing and packaging of pharmaceuticals, cosmetics, and food.Based in Italy, IMA has a massive footprint in the tea and coffee packaging market, as well as blister packaging for pharma. Their focus on digital innovation and sustainable materials keeps them at the forefront of the packaging machinery sector.

Conclusion

The landscape of packing machines is evolving rapidly, driven by the need for speed, precision, and sustainability. From the versatile shrink packing machine to the high-tech vision counting packing machine, automation is the engine of modern manufacturing. By partnering with top manufacturers like Kenwei and other global leaders, businesses can secure their competitive edge in 2026 and beyond.

FAQ

What are the primary types of packing machines?

The primary types include Form-Fill-Seal (FFS) machines, filling machines, capping/sealing machines, labeling machines, shrink packing machine systems, cartoning machines, and palletizing machines.

How do automated packing machines increase efficiency?

Automatic packing machine systems boost efficiency by performing tasks faster than manual labor, ensuring consistent output, reducing errors, minimizing material waste, and allowing for continuous operation.

What industries benefit most from packing machines?

Industries like food and beverage, pharmaceuticals, cosmetics, consumer goods, and e-commerce significantly benefit due to high production volumes and strict hygiene requirements.

What factors should I consider when choosing a packing machine?

Key factors include your product's characteristics, packaging material, required production volume, budget, available space, and the manufacturer's reliability.

Are packing machines suitable for small businesses?

Yes, semi-automatic packing machines or entry-level automatic models can be highly beneficial for small businesses by reducing labor costs and enabling scalability.

How can AI and IoT enhance packing machine performance?

AI and IoT enhance performance through predictive maintenance, real-time operational optimization, and advanced quality control with defect detection.

What are the typical components of a packing machine?

Typical components include a control system (PLC/HMI), feeding mechanism, forming unit, filling system, sealing/closing unit, and conveyor systems.

What maintenance is required for packing machines?

Regular maintenance involves cleaning, lubrication, sensor calibration, periodic inspection of wear parts, and timely software updates.

References

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

About Product choice

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

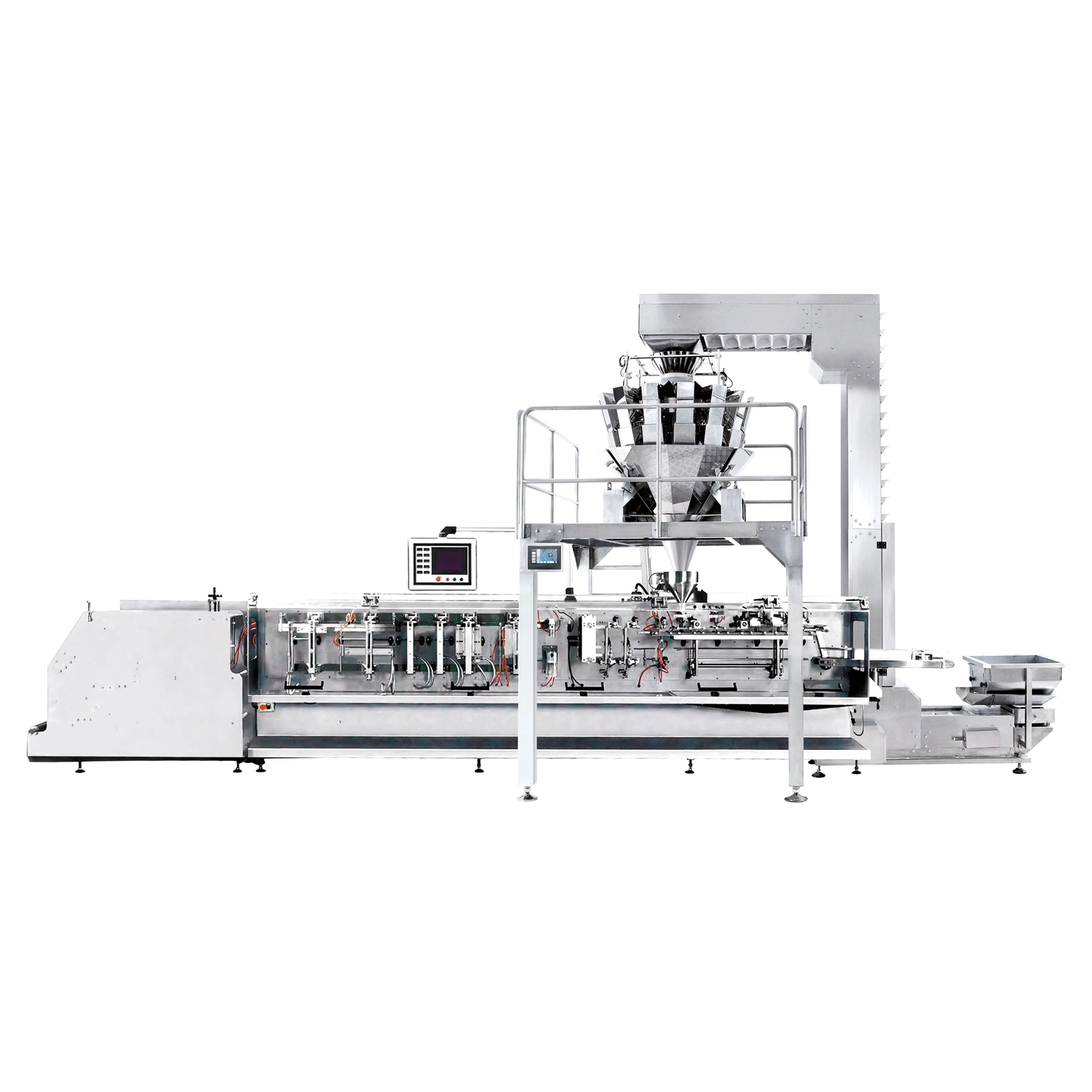

The JW-B13 Standard Pre-Made Bag Packing Machine is an advanced weighing and packing system ideal for granules, slices, and irregular products like snacks, nuts, pet food, and hardware. This fully automated line includes a vibrator feeder, Z conveyor, working platform, multihead weigher, and horizontal packing machine. It ensures high weighing accuracy, fast packing speed, and premium bagging quality—perfect for efficient, stable, and precise packaging.

The linear weigher is perfect for precise, quantitative weighing of powdery and small granular materials such as white sugar, salt, monosodium glutamate, chicken essence, milk powder, coffee, seasoning powder, and more. Available in up to 5 different specifications, this linear scale offers a maximum weighing speed of up to 70 bags per minute, making it the top choice for accurately weighing powdery materials in high-speed production environments.

The Kenwei JW-B22 Precision Food Packaging Machine with Single Head Bulk Linear Weigher is designed for heavy-duty weighing up to 50kg. It automates feeding, weighing, bag sewing, and output for maximum efficiency. Ideal for grains like corn, rice, soybeans, barley, and wheat, it ensures high accuracy and reliability for the food, chemical, and light industries, making it the top choice for bulk grain packaging.

The Kenwei JW-B16 Two Outlet Semi-Auto Sugar Weighing and Packaging Machine delivers high-precision, automated weighing for granules, slices, and irregular products like candy, coffee beans, and pet food. With a compact, cost-effective design and excellent price-performance ratio, it supports unique bag types and boosts efficiency. Optional add-ons like check weighers, metal detectors, and conveyors ensure quality control and seamless integration. Ideal for food and hardware industries.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei