Advantages of Using Multihead Weighers in Automated Packaging Lines

In today’s competitive manufacturing environment, automated packaging lines are essential for maximizing production efficiency, ensuring product consistency, and reducing labor costs. At the core of many modern packaging systems is the multihead weigher, a highly efficient and precise device that can handle a wide variety of products. Whether used in food, pharmaceuticals, or hardware industries, multihead weighers provide unparalleled speed, accuracy, and versatility, making them a crucial component of automated production.

This article explores the advantages of integrating multihead weighers into automated packaging lines and highlights why manufacturers rely on Guangdong Kenwei Intellectualized Machinery Co., Ltd. for high-performance weighing solutions.

1.Why Multihead Weighers Are Ideal for Automation

Automated packaging lines require equipment that can operate continuously without frequent human intervention. Multihead weighers meet these demands through:

- High-speed weighing: Multihead weighers can process hundreds of portions per minute depending on the number of heads and product type.

- Precision: Combination algorithms calculate the most accurate portion weight, reducing product giveaway and ensuring regulatory compliance.

- Consistency: Each package receives the target weight with minimal deviation, maintaining brand reputation and quality standards.

- Versatility: Multihead weighers can handle granular, sticky, fragile, or irregular-shaped products with ease.

These capabilities make multihead weighers an essential element of fully automated production lines.

2. Integration with Automated Systems

Multihead weighers are designed to integrate seamlessly with automated packaging equipment such as: Vertical form-fill-seal (VFFS) machines for bagging Premade pouch fillers Conveyors for product transport Metal detectors and checkweighers for quality control By connecting with packaging lines and data systems like MES or ERP, multihead weighers provide real-time production metrics, enabling manufacturers to monitor output, reduce downtime, and optimize production efficiency. Kenwei multihead weighers are specifically designed for smooth integration, with adaptable interface options and control systems compatible with various automated lines.

3. Economic Advantages of Automation

Integrating a multihead weigher into an automated line offers significant financial and operational benefits:

- Lower labor costs: Reduces manual weighing and portioning tasks

- Reduced product giveaway: Precision weighing minimizes material loss

- Higher throughput: Supports high-speed operations to meet market demand

- Minimized downtime: Intelligent algorithms and predictive maintenance reduce production interruptions

- Better quality control: Consistent weight ensures compliance with standards and regulations

Kenwei’s multihead weighers are engineered to maximize these economic benefits while maintaining high reliability.

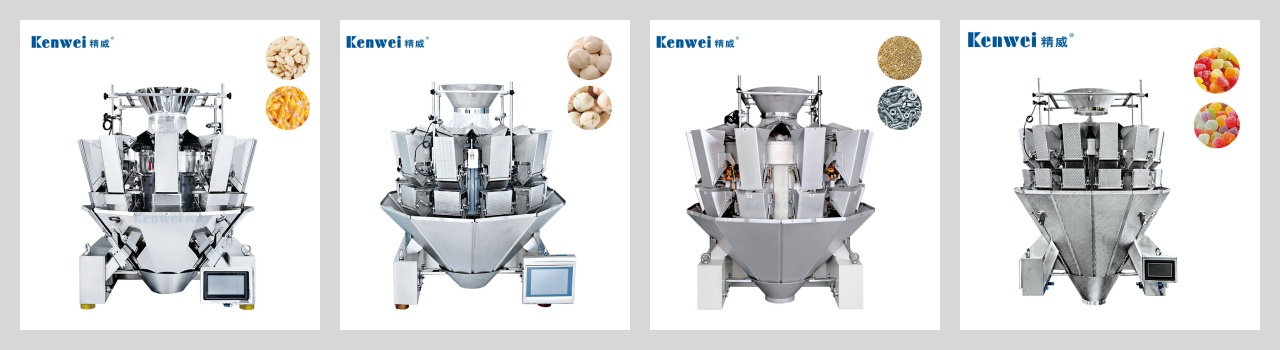

4. Application Examples Across Industries

- Food Industry Snacks, nuts, candies, dried fruits, frozen foods

- Accurate portioning reduces waste and improves packaging efficiency

- Pharmaceutical Industry Capsules, tablets, and powders Ensures strict compliance with weight tolerance and packaging regulations

- Hardware Industry Screws, bolts, and small components

- Enables high-speed counting and portioning for assembly or retail packaging

- Plastic and Chemical Granules Pellets, powders, and granular materials

Supports consistent packaging while minimizing material loss Kenwei multihead weighers are customized to suit each industry’s specific requirements, ensuring smooth integration into automated lines.

5. Operational Advantages

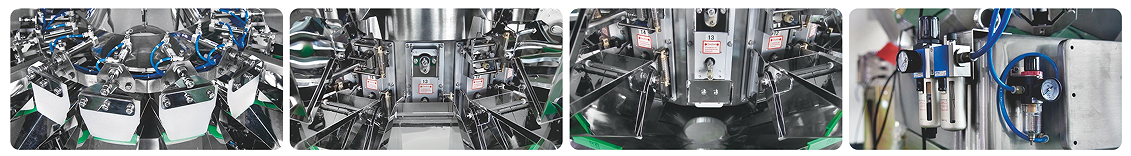

1) Smart combination algorithms Optimizes bucket selection for target weight, maintaining accuracy even at high speeds.

2) Reduced breakage and damage Specialized hoppers, soft-drop systems, and vibration control protect delicate products.

3) User-friendly operation Touchscreen HMIs and recipe management allow quick product changeover and minimal training requirements.

4) Predictive maintenance and monitoring Built-in sensors alert operators to potential issues, reducing unexpected downtime.

Kenwei machines combine these features to maximize efficiency, reliability, and ease of use for automated packaging lines.

6. Maintenance and Hygiene

Maintaining hygiene and minimizing downtime are crucial in automated lines:

- Daily cleaning of hoppers, buckets, and feeders

- Weekly calibration of load cells and sensors

- Modular design for easy disassembly and reassembly

- Durable stainless-steel construction suitable for food and pharmaceutical applications

Kenwei multihead weighers are designed for low-maintenance operation, allowing manufacturers to maintain continuous production while meeting hygiene standards.

7. Conclusion

Multihead weighers play a vital role in automated packaging lines by delivering unmatched speed, accuracy, and operational consistency. Their versatility allows seamless integration across food, pharmaceutical, hardware, and chemical industries, improving efficiency and reducing costs. For manufacturers seeking reliable, high-performance, and intelligent weighing solutions, Guangdong Kenwei Intellectualized Machinery Co., Ltd. provides a wide range of multihead weighers optimized for automated packaging systems. With Kenwei, factories can achieve higher throughput, minimize product loss, and maintain consistent quality, maximizing operational efficiency and profitability.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About Solution suggestions

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei