A Complete Guide to Rotary Packing Machines: Features, Benefits, and Applications

- What is a Rotary Packing Machine?

- Key Components of a Rotary Packing Machine

- How Rotary Packing Machines Work

- Advantages of Rotary Packing Machines

- Applications of Rotary Packing Machines

- Technological Innovations in Rotary Packaging

- Challenges in Implementation

- Future Trends in Rotary Packing Technology

- Conclusion

Rotary packing machines are transforming modern packaging with their high speed, precision, and versatility. From food to pharmaceuticals, these machines streamline operations, reduce costs, and enhance quality. Discover their components, benefits, applications, and future trends in packaging automation.

What is a Rotary Packing Machine?

A rotary packing machine is an advanced automated system that fills, seals, and delivers pre-formed pouches in a continuous rotary motion. Unlike linear or inline models, it uses a compact rotating table that boosts productivity while saving floor space. This makes it ideal for high-demand industries seeking both efficiency and quality.

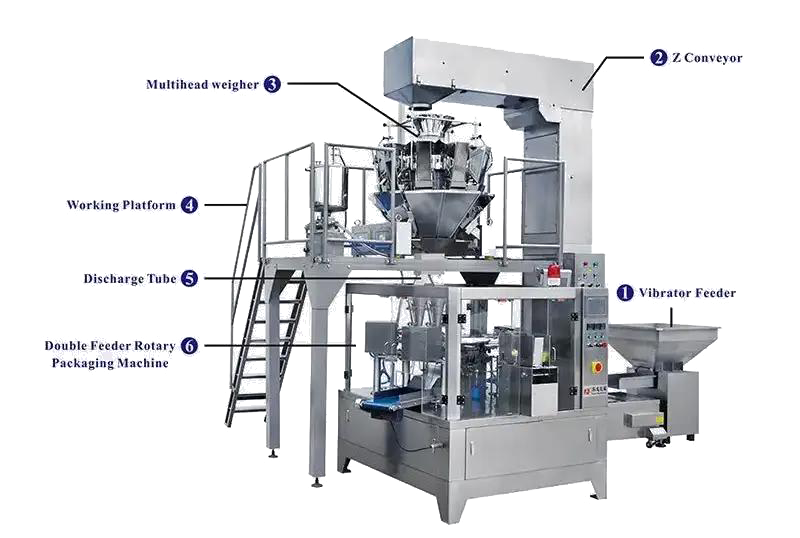

Key Components of a Rotary Packing Machine

-

Rotary Table: Ensures synchronized pouch movement, continuous operation, and reduced downtime.

-

Pouch Feeder: Loads empty pouches precisely, adaptable to multiple pouch types and sizes.

-

Filling Station: Works with multihead weighers or volumetric fillers for accuracy and waste reduction.

-

Sealing Unit: Uses heat, ultrasonic, or adhesive sealing to maintain product safety and freshness.

-

Printing Module: Prints batch codes, expiration dates, and branding directly on pouches.

-

Discharge System: Transfers finished pouches smoothly while preserving package integrity.

-

How Rotary Packing Machines Work

The process begins with loading pre-formed pouches onto the rotary table. As the table rotates, each pouch undergoes filling, sealing, and printing in sequence. Programmable logic controllers (PLCs) ensure perfect timing and coordination. Finally, completed pouches are discharged for downstream processing or shipping.

Advantages of Rotary Packing Machines

-

Compact Design: Circular layout saves space while enabling large-scale production.

-

Operational Efficiency: Handles multiple pouch types with faster setup and high-speed output.

-

Precision and Consistency: Ensures uniform filling and sealing for better product quality.

-

Cost-Efficiency: Reduces material waste, labor costs, and maintenance expenses.

Applications of Rotary Packing Machines

-

Food & Beverages: Ideal for snacks, sauces, and drinks, ensuring freshness and safety.

-

Pharmaceuticals: Used for pills and powders with airtight sealing that meets regulatory standards.

-

Personal Care: Packs creams, lotions, and shampoos with high flexibility in pouch design.

-

Agricultural & Chemicals: Provides leak-proof packaging for fertilizers, pesticides, and chemicals.

Technological Innovations in Rotary Packaging

-

Smart Sensors: Detect issues, improve reliability, and minimize downtime.

-

IoT Integration: Enables real-time monitoring and predictive maintenance.

-

Eco-Friendly Solutions: Supports recyclable materials and reduces energy usage.

-

Advanced Robotics: Enhances speed, accuracy, and precision in high-volume operations.

Challenges in Implementation

The main challenges include high initial investment, customization costs, operator training, and ongoing maintenance. Businesses must carefully evaluate ROI before deployment.

Future Trends in Rotary Packing Technology

-

AI Integration: Enhances efficiency and reduces operational errors.

-

Sustainable Packaging: Stronger focus on green, recyclable materials.

-

Flexible Modular Design: Machines that adapt to changing production demands.

Conclusion

Rotary packing machines are reshaping modern packaging by combining speed, precision, and adaptability. From food and pharmaceuticals to personal care and chemicals, they deliver consistent quality and operational efficiency. With innovations in AI, IoT, and eco-friendly design, rotary machines are set to play a key role in the future of packaging automation.

About products customization

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei