Top 10 Food Packing Machines for 2026

- Why Food Packing Machines Matter in 2026

- What Is a Food Packing Machine?

- Types of Food Packing Machines:

- Integration with Other Equipment:

- How Food Packing Machines Work

- Top 10 Food Packing Machines for 2026

- 1. Syntegon Technology (Germany)

- 2. Kenwei (China)

- 3. MULTIVAC (Germany)

- 4. Tetra Pak (Sweden/Switzerland)

- 5. IMA Ilapak (Italy/Switzerland)

- 6. Theegarten‑Pactec (Germany)

- 7. Paxiom Packaging Systems (USA/Canada)

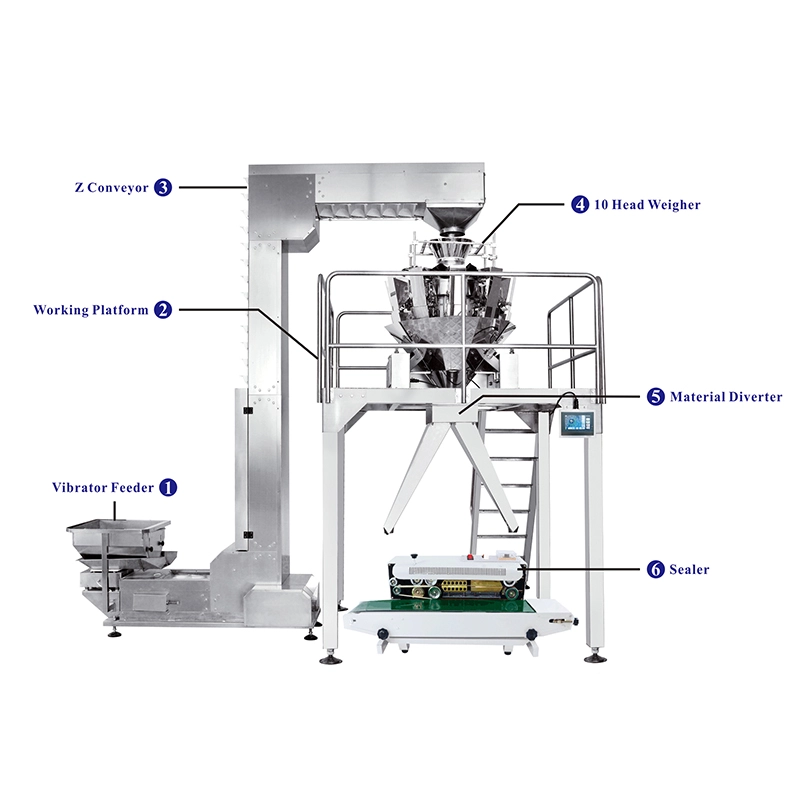

- 8. GEA Group (Germany)

- 9. Marchesini Group (Italy)

- 10. Cermex (France/Tetra Laval)

- Comparison Table

- How to Choose the Best Food Packing Machine for Your Factory

- Cost Guide (Food Packing Machine Price)

- Why Kenwei

- FAQs about Food Packing Machine

- What is the best food packing machine for small businesses?

- How accurate is a multihead weigher?

- Which machine is best for snacks?

- Food packing machine vs manual packing: Which is better?

- How long does a food packing machine last?

- Can vacuum packaging extend shelf life?

- Are stick pack machines suitable for powders?

- Is maintenance complicated?

- Conclusion

Discover Kenwei’s top 10 food packing machines for 2026. High-speed, precision packing solutions for your food product.

Why Food Packing Machines Matter in 2026

By 2026, the global food industry is going to need a lot more packaging that is high-quality, safe, and efficient. A food packing machine is more than just convenient. It's essential for factories that want to cut labor costs, maintain hygiene standards, and meet global production demands. Automated solutions, like automatic food packing machine lines, are pretty much standard these days for snack foods, powders, frozen items, and ready-to-eat meals.Manufacturers are now on the lookout for food packing machines that can do all the weighing, bagging, sealing, and inspection in just one line. Buyers are on the lookout for the best food packing machines to boost their output, minimize errors, and meet strict hygiene rules. Modern lines sometimes include a vacuum packing machine for food, which makes products last longer and safer.

What Is a Food Packing Machine?

A food packing machine is a special kind of equipment that's designed to automate the process of filling, sealing, and labeling food products. Its main goals are to make sure the product is always top-notch, boost production efficiency, and meet strict rules about hygiene and safety. Modern food packing machines can handle a wide range of products and packaging styles, from granular snacks to liquids and powders. You can set them up for semi-automatic, fully automatic, or smart IoT-enabled operations.Modern food packing machines can handle a wide range of products and packaging styles, from granular snacks to liquids and powders. You can set them up for semi-automatic, fully automatic, or smart IoT-enabled operations, often integrating a multihead weigher for packaging to ensure precise portioning and consistent product weight.

Types of Food Packing Machines:

-

Product Type Examples Automation Level Notes Granular / Dry Foods Nuts, rice, snacks Semi-Automatic / Fully Automatic Ideal for consistent portioning of small solid items. Powdered Products Spices, coffee, protein powders (food supplement powder stick pack packaging machines) Semi-Automatic / Fully Automatic Precision dosing is critical; stick packs popular for supplements. Liquids & Sauces Soups, sauces, yogurt Fully Automatic / Smart Hygienic design required; often integrated with capping/sealing. Solid / Frozen Foods Frozen vegetables, meat (vacuum packing machine for food) Fully Automatic Vacuum packaging preserves freshness and extends shelf life. Snack Items Chips, candy, baked goods Semi-Automatic / Fully Automatic High-speed lines optimize output; can integrate metal detection.

Integration with Other Equipment:

Today's food packaging machines are often combined with all kinds of equipment, like multihead weighers, linear weighers, metal detectors, checkweighers, and vacuum packaging machines. Together, they form a complete automated line for packaging food products. Multihead and linear weighers make sure you get the right amount, and metal detectors and checkweighers make sure everything is safe and accurate. Vacuum packing is great for keeping frozen or perishable items fresh. Kenwei provides all-in-one solutions that connect weighing, filling, sealing, inspection, and vacuum packaging, so you can have scalable, high-efficiency production lines.

How Food Packing Machines Work

A typical food packing machine operates through these key steps:

-

Product feeding: Items are delivered from hoppers or conveyors.

-

Weighing: Multihead or linear weighers ensure precise quantities.

-

Bag formation: Vertical Form-Fill-Seal (VFFS) or pre-made bags are used.

-

Sealing: Heat or vacuum sealing ensures freshness, especially when using a food vacuum packing machine.

-

Inspection: Metal detectors and checkweighers verify quality.

-

Discharge: Finished products are sent for packing or storage.

Using a Kenwei automatic food packing machine makes it so that everything from weighing to inspection is done in a smooth way. This makes a reliable food packaging line that can include a vacuum packing machine for food that is sensitive.

Top 10 Food Packing Machines for 2026

1. Syntegon Technology (Germany)

-

Core Technologies: VFFS, Flow-wrapping, Cartoning, Case Packing, Complete Packaging Lines

-

Key Strengths: Highly automated modular systems, German engineering precision, scalable for various production sizes

-

Ideal Applications: Snacks, bakery items, frozen foods, dry goods

-

Notable Features: Integrated inspection, metal detection, and end-of-line automation

-

Advantages: Complete end-to-end packaging solutions with high reliability and flexible layout options

-

2. Kenwei (China)

-

Core Technologies: Multihead weighers, Bagging lines, Metal detectors, Checkweighers, Vacuum packaging

-

Key Strengths: One-stop customized solutions combining weighing, packing, inspection, and vacuum packaging

-

Ideal Applications: Snacks, powders, frozen foods, granules, food supplement powders

-

Notable Features: Modular design, high-speed automatic food packing machine, integration with small packing machines for food products

-

Advantages: Global service network, full automation, flexible layout, tailored solutions for various product types

-

3. MULTIVAC (Germany)

-

Core Technologies: Thermoforming machines, Tray sealers, Chamber vacuum machines

-

Key Strengths: Hygienic design, high-barrier sealing, MAP and vacuum options

-

Ideal Applications: Meat, cheese, ready meals, fresh foods

-

Notable Features: High precision sealing, easy cleaning, flexible pack formats

-

Advantages: Industry-leading vacuum and thermoforming packaging systems for hygienic food safety

-

4. Tetra Pak (Sweden/Switzerland)

-

Core Technologies: Aseptic filling, Carton packaging, Liquid packaging lines

-

Key Strengths: Continuous sterile filling and sealing, global support

-

Ideal Applications: Milk, juice, dairy, beverages

-

Notable Features: Hygienic, aseptic, automated filling and packaging

-

Advantages: World-leading aseptic packaging technology and high-speed production lines

-

5. IMA Ilapak (Italy/Switzerland)

-

Core Technologies: VFFS, Flow wrapping, Stick pack machines

-

Key Strengths: Flexible packaging formats, precise portion control

-

Ideal Applications: Powders, snacks, confectionery, baked goods

-

Notable Features: Hygienic design, minimal material waste, high-speed operation

-

Advantages: Strong in single-serve, stick packs, and flexible automation for small to medium-scale food products

-

6. Theegarten‑Pactec (Germany)

-

Core Technologies: Flow wrappers, Candy cartoners, Confectionery lines

-

Key Strengths: High-speed, gentle handling of small items

-

Ideal Applications: Candy, chocolate, bite-size confectionery

-

Notable Features: Automated feeding, wrapping, and cartoning

-

Advantages: Optimized for delicate or small-format food packaging, reliable and precise operation

-

7. Paxiom Packaging Systems (USA/Canada)

-

Core Technologies: Vertical FFS (VerTek, XPdius), Horizontal baggers, Pre-made pouch machines

-

Key Strengths: High versatility for multiple bag types, easy line integration

-

Ideal Applications: Frozen foods, candy, snacks, granular or sticky products

-

Notable Features: Customizable packaging formats, scalable automation

-

Advantages: Flexible, cost-efficient, and suitable for both small and large production lines

-

8. GEA Group (Germany)

-

Core Technologies: Thermoformers (PowerPak), Vertical SmartPacker, Skin/MAP/Vacuum packaging

-

Key Strengths: High-speed, multi-format, hygienic design

-

Ideal Applications: Meat, poultry, cheese, convenience foods

-

Notable Features: Flexible pack formats, easy maintenance, energy-efficient operation

-

Advantages: Modular, efficient, multi-format packaging suitable for large factories

-

9. Marchesini Group (Italy)

-

Core Technologies: Stick pack, Sachet, Strip pack, FFS lines

-

Key Strengths: Precision small-dose filling, flexible packaging line automation

-

Ideal Applications: Spices, supplements, powders, single-serve food products

-

Notable Features: Hygienic, low material waste, fast changeover between formats

-

Advantages: Engineering excellence for flexible, small-format packaging needs

-

10. Cermex (France/Tetra Laval)

-

Core Technologies: Case packers, Shrink wrappers, Palletizers, End-of-line automation

-

Key Strengths: High throughput, reliable secondary packaging automation

-

Ideal Applications: Cartoned foods, bagged foods, boxed products

-

Notable Features: Fully automatic end-of-line integration, scalable for large factories

-

Advantages: Efficient automation of final packaging steps, reduces labor, increases throughput

-

Comparison Table

| Company | Machine Type / Focus | Speed / Output | Accuracy | Best For | Automation Level | Price Range |

|---|---|---|---|---|---|---|

| Syntegon (Germany) | VFFS, Flow Wrap, Cartoning | 50–600 bags/min | ±0.5–2 g | Snacks, bakery, frozen, dry foods | Fully automatic | High-end |

| Kenwei (China) | Multihead Weigher + Bagger + Vacuum + Checkweigher | 20–500 bags/min | ±0.5–2 g | Snacks, powders, frozen foods, granules | Fully automatic, integrated line | Mid–High |

| MULTIVAC (Germany) | Thermoforming, Tray Sealer, Vacuum | 30–450 packs/min | ±1–3 g | Meat, cheese, ready meals | Fully automatic | High-end |

| Tetra Pak (Sweden/CH) | Aseptic Filling, Carton Packaging | 1000–6000 packs/hour | ±1% volume | Milk, juice, beverages | Fully automatic | High-end |

| IMA Ilapak (Italy/CH) | VFFS, Flow Wrapper, Stick Pack | 50–700 packs/min | ±0.5–1 g | Powders, snacks, confectionery | Fully automatic | Mid–High |

| Theegarten-Pactec (Germany) | Candy Wrappers, Cartoners | 100–800 items/min | ±0.5–1 g | Candy, chocolate, bite-size foods | Fully automatic | Mid–High |

| Paxiom (USA/Canada) | VFFS, Horizontal Bagger, Pre-made Pouch | 30–600 bags/min | ±0.5–2 g | Frozen foods, snacks, candy | Fully automatic | Mid–High |

| GEA Group (Germany) | Thermoformer, Vertical SmartPacker, Vacuum/MAP | 50–500 packs/min | ±1–3 g | Meat, poultry, cheese, convenience foods | Fully automatic | High-end |

| Marchesini Group (Italy) | Stick Pack, Sachet, Strip Pack | 50–800 packs/min | ±0.5–1 g | Spices, supplements, powders | Fully automatic | Mid–High |

| Cermex (France/Tetra Laval) | Case Packer, Shrink Wrapper, Palletizer | 20–200 cases/min | ±1% | Bagged or cartoned foods | Fully automatic | High-end |

How to Choose the Best Food Packing Machine for Your Factory

-

Picking the right food packing machine is key to getting the most out of your investment, making sure your products are top-notch, and getting a solid return on your money. The best machine depends on the type of food, how much you need to produce, the type of packaging, and how much automation you need. Modern factories often integrate weighing, filling, sealing, and inspection equipment, including vacuum packing machines for food, to form a complete automatic food packing machine line. Understanding the benefits of using a multihead weigher in food packaging—such as precise portion control, reduced product giveaway, and faster throughput—can also help you make an informed choice. To make an informed choice, consider the following factors:

-

Product Type: Solid, liquid, powder, frozen, or snack products determine the suitable machine type and configuration.

-

Packaging Material: Options include pouches, trays, vacuum packs, or stick packs; compatibility affects machine selection.

-

Output Requirement: Calculate the required bags per minute or hour to meet production targets.

-

Weighing Accuracy: ±0.5 g for snacks and powders, ±1–2 g for bulk foods; precision is key for consistency and compliance.

-

Factory Space & Layout: Machine footprint and line arrangement must fit available space while allowing smooth workflow.

-

Automation Upgrade: Consider optional modules like inspection, labeling, conveyors, or integration with vacuum packing machine for food.

-

Hygiene & Safety: Easy cleaning, FDA/CE compliance, and food-safe materials ensure regulatory compliance.

-

ROI Consideration: High-speed automatic food packing machines reduce labor, minimize waste, and improve overall efficiency.

-

Cost Guide (Food Packing Machine Price)

| Tier | Description | Price Range | ROI Notes |

|---|---|---|---|

| Entry-level | Small small packing machine for food products | $5k–$15k | Suitable for startups, low output |

| Mid-range | Single VFFS or linear line | $30k–$80k | Moderate output, flexible |

| High-end | Multihead weigher + VFFS | $80k–$200k | Large factory, high precision |

| Customized line | Kenwei full automatic food packing machine line | $120k–$350k | Integrated weighing, vacuum packing machine for food, inspection, highest ROI |

Why Kenwei

-

Kenwei is a top supplier of high-speed, precise food packing machines and integrated packaging solutions. Their know-how makes sure that they're efficient, flexible, and reliable across a wide range of products. Here are some of the main benefits:

-

Global Multihead Weigher Expertise: Leading precision and speed for accurate portioning.

-

High-Speed Automatic Lines: Fully integrated packing machine for food products for consistent output.

-

Customization: Solutions for powders, snacks, frozen foods, and stick packs.

-

Worldwide Service Network: Installation, commissioning, and training support.

-

One-Stop Solution: Weighing, packing, metal detection, checkweighing, and vacuum packing machine for food included.

-

FAQs about Food Packing Machine

-

What is the best food packing machine for small businesses?

- A small packing machine for food products is perfect for startups or labs with low output. Tabletop or semi-automatic machines are cheaper and still give you consistent quality. Some of these compact units even incorporate rotary packing machines, which enhance speed and efficiency, while other rotary packing machines in slightly larger models provide higher throughput without compromising accuracy.

-

How accurate is a multihead weigher?

- Most multihead weighers can get within ±0.5 g for snacks, powders, and small items, which makes them great for high-speed automatic food packing machine lines.

-

Which machine is best for snacks?

- High-speed multihead weigher packing machines or integrated snack lines like Ishida or Kenwei are preferred.

-

Food packing machine vs manual packing: Which is better?

- An automatic food packing machine can help you get more done, and it can make sure that the quality and cleanliness are always consistent, compared to using a manual packing method.

-

How long does a food packing machine last?

- Industrial packing machines for food products usually last about 10–15 years if you take care of them.

-

Can vacuum packaging extend shelf life?

- Yes. A food vacuum packing machine removes oxygen, which helps keep food fresh and increases shelf life by 2–5 times.

-

Are stick pack machines suitable for powders?

- Yes. These machines are perfect for packaging food supplement powder sticks, protein powders, and instant beverages.

-

Is maintenance complicated?

- You've got to clean, inspect, and lubricate your food vacuum pack machine or automatic line, but modern designs make it easier.

Conclusion

Picking the right food packing machine is key to getting the most out of your production, keeping your food safe, and getting a good return on your investment. From snacks and powders to frozen foods and supplements, the right equipment lets you automate and scale things up while keeping the product quality consistent. Global trends are pointing more and more towards high-speed, hygienic, and flexible automatic food packaging machines. If you're thinking about getting a small packing machine for food products or a complete integrated Kenwei line, it's important to understand your production needs and what your machine can do.That way, you can make sure you're getting long-term success.If you need professional advice or customized solutions, contact Kenwei today to find the perfect food packing machine for your factory.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

About After Sales Support

How about the after-sales service?

Warranty :2 years

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

The Kenwei JW-B20 Semi-Automatic Multi-Function Packaging Machine with Linear Weigher is ideal for powders and granules like sugar, salt, rice, coffee, and milk powder. It automates feeding, weighing, and output with high accuracy and efficiency. Compact and cost-effective, it suits various bag types not supported by standard machines, making it perfect for flexible, space-saving packaging needs.

Kenwei Rotary Packaging and Weighing System with Multihead Weigher is an efficient food packing machine designed for peanuts and melon seeds. This rotary packaging machine ensures high-speed, precise weighing and sealing, making your production smarter and faster.

The Kenwei Automatic Canning and Weighing Filling System offers a fully integrated solution for efficient food packaging. Featuring a multihead weigher, Z-type conveyor, vibrator feeder, and capping machine, it automates feeding, weighing, filling, and labeling with high accuracy. Perfect for snacks, puffed foods, fruits, hardware, and granular materials in cans. Ideal for modern production lines.

The Single Head Belt Linear Weigher is constructed from food-grade stainless steel, making it ideal for materials with slight stickiness, such as brown sugar, black sugar, and industrial salt, which have low fluidity. This linear scale features a single hopper with a 15-liter capacity, designed for weighing larger materials efficiently.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei