Guangdong Kenwei : Strengthening Fire Safety Through Practical Drills and Upholding the Principle of “Fire Safety for All, Life First”

As the 2025 National Fire Safety Publicity Month arrives as scheduled, enterprises and communities across the country are actively carrying out a variety of fire safety campaigns and emergency drills under the theme “Fire Safety for All, Life First.” These initiatives aim to further enhance public fire safety awareness and reinforce the social-level fire prevention barrier.

On the afternoon of November 13, Guangdong Kenwei Intellectualized Machinery Co., Ltd. followed this nationwide effort by conducting an intensive and highly efficient emergency fire drill, integrating the fire-safety principle into everyday production practices and strengthening the company’s safety management system.

A piercing alarm broke through the air as dense “smoke” quickly filled the second-floor electronics room—the simulated fire source—marking the official start of a realistic fire emergency exercise.

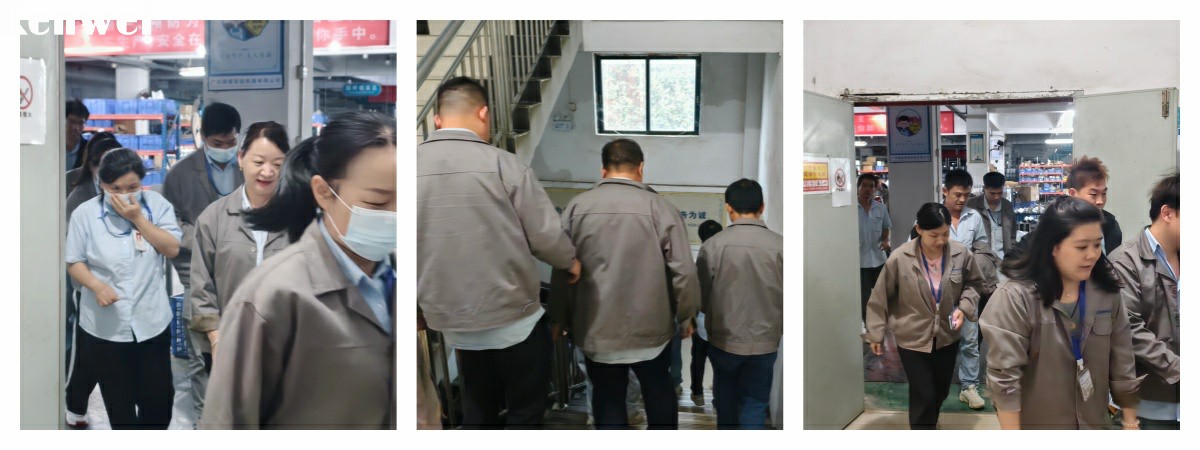

Following the command of the on-site chief director, Kenwei’s volunteer firefighting team responded swiftly and cooperated seamlessly. Each group performed their duties efficiently, guiding employees from various departments to evacuate the building through designated emergency routes and assemble at the appointed safe area.

Throughout the drill, every step was executed smoothly and with strong coordination, fully demonstrating the company’s mature ability to handle fire-related emergencies. The exercise not only tested team cooperation and evacuation procedures but also enhanced employees’ fire safety awareness in real-life scenarios. It strengthened their self-rescue and mutual-aid capabilities, building a solid “human defense” foundation for workplace safety.

After the drill, employees assembled neatly in the warehouse yard for a comprehensive review by the Manufacturing Department Deputy Manager. While acknowledging the overall effectiveness of the exercise, he also pointed out areas for improvement and emphasized: “Fire safety is the lifeline of production. Every employee must uphold the concept of ‘Fire Safety for All, Life First’ and practice safety responsibilities through daily actions to ensure the company meets its annual safety targets.”

The leader of the volunteer fire team’s extinguishing unit then continued the session by demonstrating the correct use of fire extinguishers and fire hydrants. Members of the volunteer firefighting team participated in hands-on practice to enhance their real-world firefighting skills.

Kenwei Intelligent has consistently adhered to routine fire drills, safety training sessions, and hazard inspections as part of its commitment to the principle of “Fire Safety for All, Combining Prevention and Control.” The company not only strengthens internal safety defenses but also extends its fire safety responsibilities to the broader community—an effort vividly demonstrated on the morning of November 7.

On November 7, the company actively supported the local fire safety initiative by participating in the 2025 Third “Ankang Cup” Fire Skills Competition and the Launch Ceremony of the Fire Safety Publicity Month, organized by Fussha Town. In recognition of its long-term dedication to local fire safety initiatives, Kenwei received the “Outstanding Contribution to Fire Safety Public Welfare” award, highlighting the government’s appreciation of the company’s social responsibility efforts and further reinforcing its foundation for future fire safety work.

From actively engaging in local fire safety events and fulfilling social responsibilities to conducting internal drills and strengthening workplace safety, Kenwei demonstrates a comprehensive and responsible approach to fire protection. Moving forward, the company will continue to uphold its safety obligations, refine internal fire management, strengthen emergency response teams and facilities, and deepen its involvement in local fire safety public welfare.

Kenwei remains committed to building a robust fire safety system that supports employee well-being, high-quality corporate development, and the advancement of local fire services.

About products customization

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

About Product choice

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

About Solution suggestions

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei