Kenwei Best Food Inspection Metal Detector: Reliable & Accurate

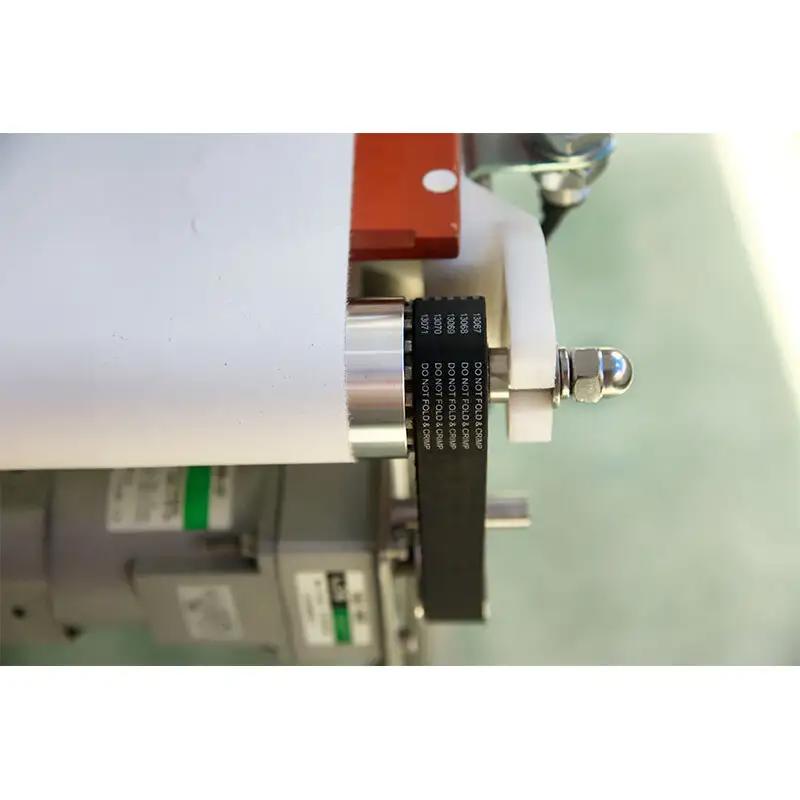

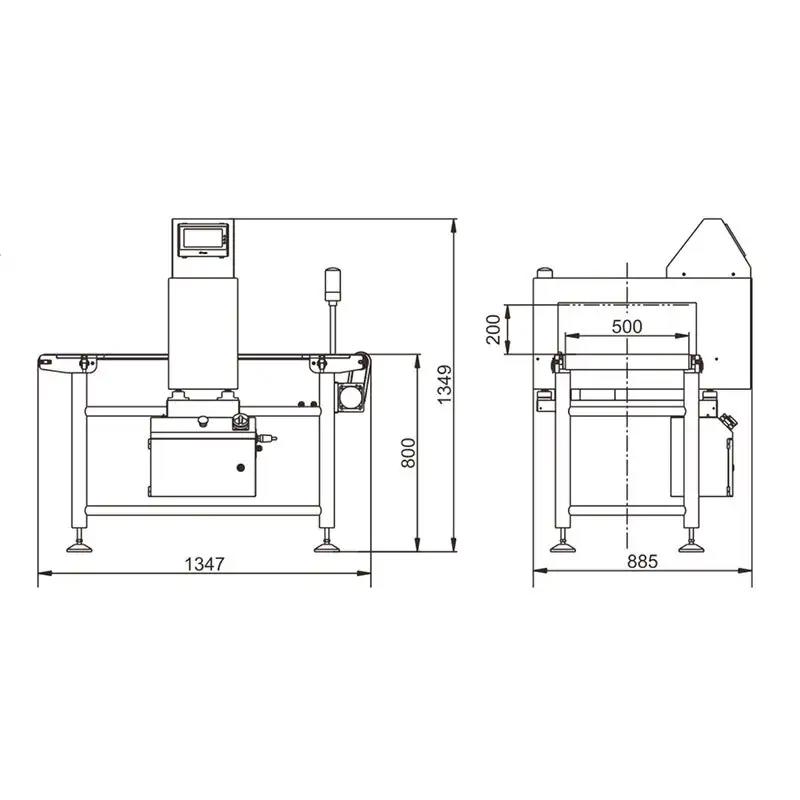

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Kenwei Best Food Inspection Metal Detector: Precision You Can Trust

Ensure the highest quality and safety of your food products with the Kenwei best food inspection metal detector. As an industry pioneer in automated weighing and packaging, Kenwei delivers state-of-the-art inspection solutions uniquely designed for the demanding needs of modern food processing and packaging lines. Our advanced metal detector offers exceptional sensitivity and stability, making it ideal for detecting even the smallest metal contaminants commonly encountered in food manufacturing.

Backed by Kenwei’s legacy of innovation and engineering, the best food inspection metal detector integrates seamlessly with multi-head weighers, linear weighers, and check weighers, providing an all-in-one inspection and quality assurance system. High-speed operation and pinpoint accuracy ensure your production line maintains maximum throughput without compromising safety or compliance with international standards.

Our customizable solutions and user-friendly interfaces empower operators with real-time data and intuitive controls, minimizing downtime and optimizing productivity. Supported by a full suite of services — from design and installation to technical training and after-sales support — Kenwei provides peace of mind and outstanding value. Based in Fusha High-tech Industrial Park, Guangdong, we have built a global reputation for excellence, reliability, and fast response.

Choose Kenwei for your food inspection metal detecting needs and benefit from advanced technology, superior accuracy, and dependable service. Protect Kenwei, ensure product integrity, and achieve the highest industry standards with Kenwei—the best food inspection metal detector manufacturer.

Learn more at (https://www.kenweigroup.com/)

Picture Show

Certifications

ICR Polska/VC/LU201107 Check Weigher

2021 Outstanding Contribution to Enterprise Tax Payment Third Prize

Q&A

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

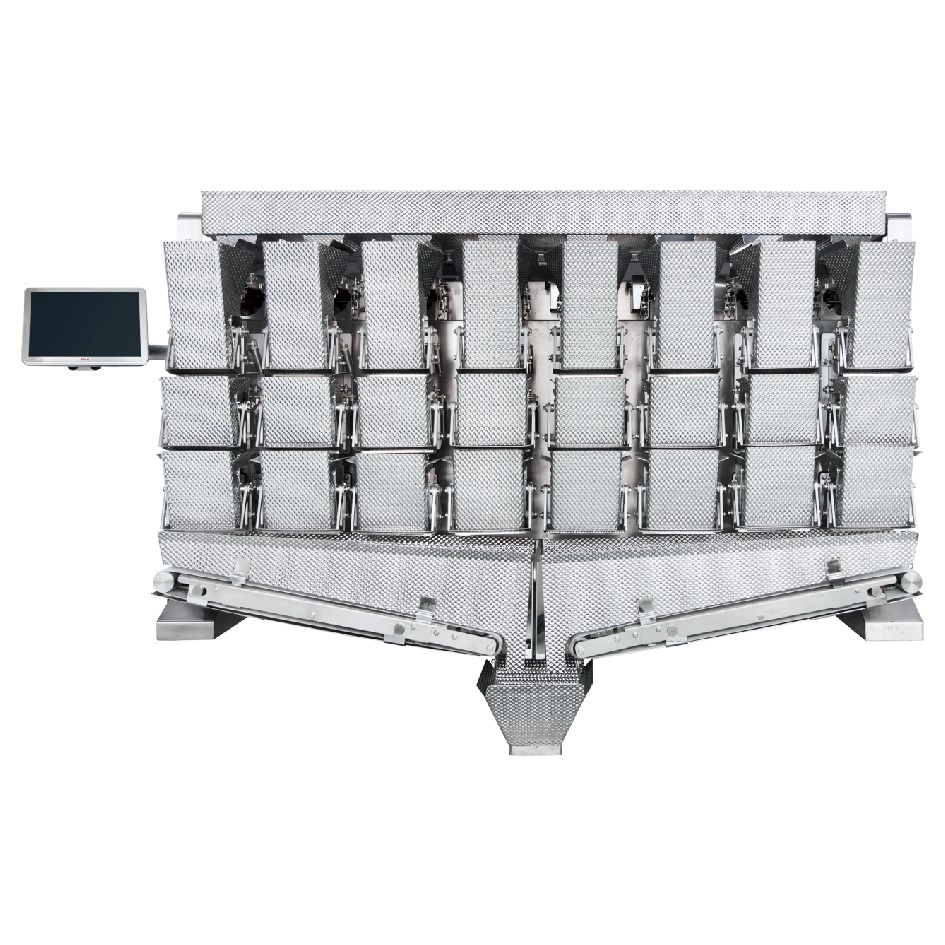

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

If you have another questions, please feel free to contact us.

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Fully Automatic Twin Packaging Machine for Granules Snack Foods Weighing JW-B2

Kenwei's JW-B2 Fully Automatic Twin Packaging Machine boasts 14-head multihead weighing for precise granule and snack food packaging. This high-speed automatic packaging machine offers efficient twin-packaging, maximizing your production output. Ideal for food manufacturers seeking enhanced speed and accuracy.

Belt Feeding Multihead Weigher with 3-Layer Hopper for Accurate Weighing Precision

The three-layer belt feeding weigher features a compact linear case design and a three-layer hopper structure, optimizing space efficiency. By using belt feeding instead of traditional vibration feeding, this weigher is particularly effective for handling viscous materials such as mustard pickles, pickles, small fish, and other low-fluidity products. To solve the issue of material sticking, the weigher is equipped with a springless scraper hopper, making cleaning faster and more convenient. Ideal for sticky materials and those with poor fluidity, this product provides reliable support for efficient weighing and packaging operations.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei