8 Fast-Growing Categories of Popular Food Packaging and Processing Machines 2026

- What are Food Packaging Machines?

- Why They Matter

- What are Food Processing Machines?

- Key Takeaways: Your Quick Guide to Food Packaging Machinery

- The Indispensable Role of Food Packaging Machinery in Modern Industry

- Core Benefits

- Demystifying Food Packaging Machine Types: A Comprehensive Breakdown

- By Function

- By Form Factor & Operation

- Key Features and Innovations Driving Modern Food Packaging (2026 & Beyond)

- Navigating the Selection Process: How to Choose the Right Food Packaging Machine

- Selection Checklist

- Optimizing Performance: Maintenance Tips & Best Practices

- Expert Insights: Common Mistakes to Avoid When Investing

- The Future of Food Packaging: Trends and Predictions for 2026+

- 8 Fast-Growing Types of Popular Food Packaging and Processing Machines

- Frequently Asked Questions (FAQ)

- What are the primary benefits of using a food packaging machine?

- How do I determine the right type of food packaging machine for my product?

- What are the key differences between VFFS and HFFS machines?

- Can food packaging machines handle different types of food products and materials?

- What maintenance is required for a food packaging machine?

- How much does a new food packaging machine typically cost?

- What role does automation play in modern food packaging?

- Are there sustainable options available for food packaging machinery?

- Conclusion

- References

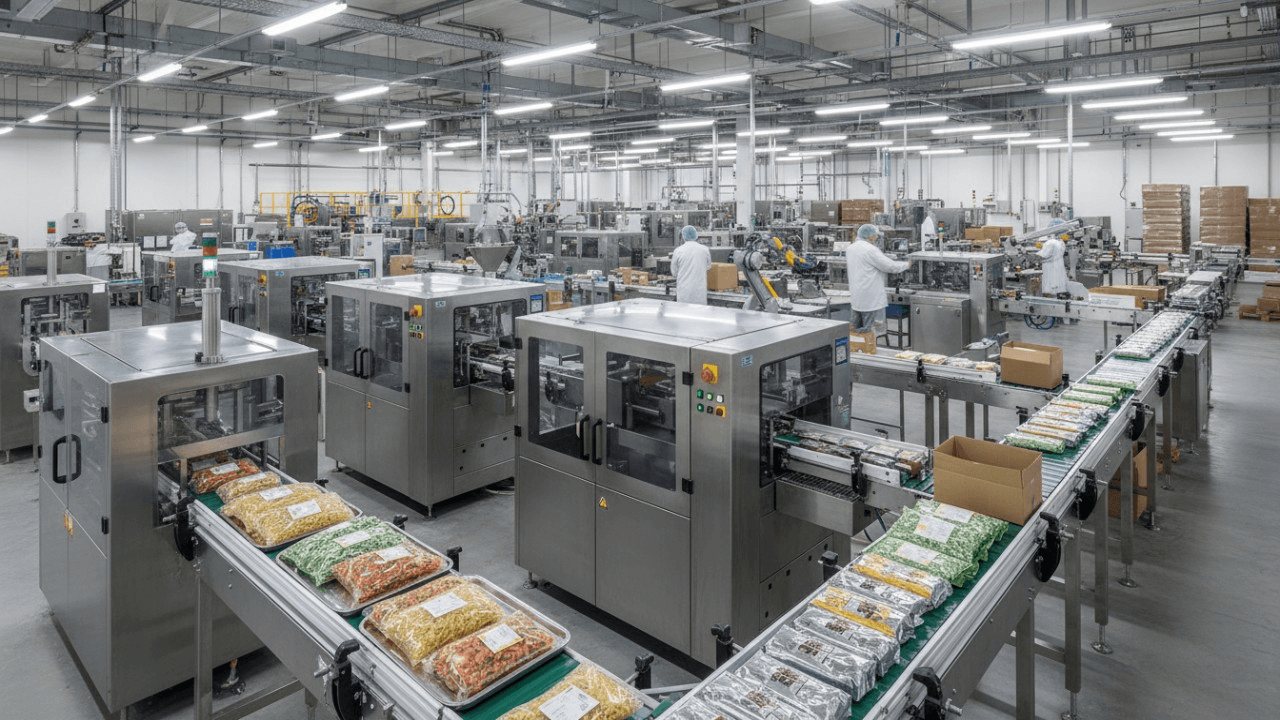

A comprehensive 2026 guide to the fastest-growing food packaging and processing machines. Explore top categories like VFFS and vacuum sealers, analyze costs, and understand future trends in AI and sustainability to boost your production line.

What are Food Packaging Machines?

Food packaging machines are automated or semi-automated systems designed to enclose food products in containers like bags, pouches, trays, or jars to protect them during distribution and storage. By 2025, the global market for these machines is valued at approximately $22.1 billion, driven by the need for hygiene, extended shelf life, and efficiency. These systems range from simple food packaging machines for small business operations to complex commercial food packaging machine lines capable of handling thousands of units per minute.

Why They Matter

· Protection: Prevents physical damage and contamination.

· Preservation: Technologies like vacuum sealing extend freshness.

· Efficiency: Automates repetitive tasks, significantly reducing labor costs.

What are Food Processing Machines?

Food processing machines are equipment used to transform raw ingredients into consumable food products through physical or chemical means, such as mixing, cooking, cutting, or pasteurizing. While a packaging machine for food focuses on the final enclosure, processing machines handle the preparation. For example, an industrial mixer prepares the dough, while the packaging machine wraps the final cookie. Both are vital, but they serve distinct stages of the production line.

Key Takeaways: Your Quick Guide to Food Packaging Machinery

· Efficiency is King: Automated food packaging machines reduce labor costs and increase throughput by up to 300%.

· Diverse Options: From frozen food packaging machine models to pet food packaging machine lines, there is a specialized solution for every product.

· Strategic Investment: Costs range from $1,000 for semi-auto units to over $150,000 for fully integrated lines.

· Future-Proofing: 2026 trends focus on AI integration, food+packaging+machine connectivity (IoT), and sustainable mono-materials.

· Compliance: Modern machines help meet strict FDA and HACCP hygiene standards.

The Indispensable Role of Food Packaging Machinery in Modern Industry

Food packaging machinery serves as the backbone of modern food supply chains by ensuring product safety, consistency, and brand appeal while minimizing waste. According to recent 2024 data, the demand for these machines is growing at a CAGR of 7.3%, highlighting their critical role in scaling operations.

Core Benefits

1. Efficiency and Productivity Gains: Automating manual tasks allows manufacturers to meet high demand without expanding their workforce significantly.

2. Enhanced Product Safety and Hygiene: Automated lines, such as a vacuumized food packaging machine, remove human contact from the equation, ensuring a sterile environment.

3. Extended Shelf Life: Advanced sealing techniques (like MAP) preserve freshness, allowing products to travel further and stay on shelves longer.

4. Brand Consistency: Machines ensure every bag of snacks or bottle of sauce looks identical, building consumer trust.

Demystifying Food Packaging Machine Types: A Comprehensive Breakdown

Food packaging machines are categorized by their specific function (filling, sealing, wrapping) or their operational form factor (vertical, horizontal, rotary).

By Function

· Filling Machines: Essential for dosing liquids, powders, or granules. Precise weighing is critical here; specifically, Multihead Weighers enhance snack food packaging by ensuring exact portion control at high speeds.

· Sealing Machines: Includes heat, induction, and ultrasonic sealers that ensure airtight closure.

· Vacuum Packaging Machines: A vacuum packaging machine for food removes air to prevent oxidation, widely used for meats and cheeses.

· Labeling Machines: Applies branding and regulatory info, often integrated into the main line.

By Form Factor & Operation

· Vertical Form Fill Seal (VFFS): Forms a bag from a roll of film, fills it, and seals it. This is the standard snack food packaging machine.

· Horizontal Form Fill Seal (HFFS) / Flow Wrappers: Wraps solid items horizontally. Ideal for cookies and candy bars.

· Premade Pouch Filling: Picks up a finished bag, opens it, fills it, and seals it. Popular for premium pet foods.

· Tray Sealing: Seals a film lid onto a tray. Common in frozen food packaging machine applications for ready meals.

Key Features and Innovations Driving Modern Food Packaging (2026 & Beyond)

Modern food packaging machine manufacturers are prioritizing connectivity, flexibility, and sustainability to meet the demands of Industry 4.0. The "Connected Platforms" trend for 2025 emphasizes utilizing AI to optimize supply chains and reduce waste.

· Smart Controls & HMI: Intuitive touchscreens allow operators to switch products with a single tap.

· Robotics & AI: AI-driven vision systems now inspect seals and labels in real-time, rejecting defects automatically.

· IoT & Predictive Maintenance: Machines alert managers before a part fails, preventing costly downtime.

· Sustainability: New machines are engineered to run eco-friendly, thinner, or biodegradable films without jamming.

Navigating the Selection Process: How to Choose the Right Food Packaging Machine

Selecting the right packaging machine for food requires balancing your current production volume with future scalability and budget constraints. Many startups search for food packaging machines for small business only to realize they need industrial-grade speed sooner than expected.

Selection Checklist

1. Assess Your Product: Is it liquid, solid, or powder? A frozen food packaging machine requires different cold-resistance features than a dry pasta packer.

2. Production Volume: Do you need 10 bags per minute (semi-auto) or 200 (fully auto)?

3. Material Compatibility: Ensure the machine works with your chosen sustainable films or pouches.

4. Budget & ROI: Entry-level vacuum sealers cost under $2,000, while high-speed food packaging machines for industrial use can exceed $100,000.

5. After-Sales Support: Look for food packaging machine manufacturers that offer local spare parts and training.

Optimizing Performance: Maintenance Tips & Best Practices

Proper maintenance of your food packaging machine is the single most effective way to ensure longevity and consistent output quality. Neglect leads to hygiene risks and expensive repairs.

· Daily Sanitation: Clean surfaces to prevent cross-contamination, especially for vacuumized food packaging machine units handling raw meat.

· Preventative Schedule: Lubricate moving parts and replace sealing strips before they wear out.

· Staff Training: Ensure operators understand the specific settings for different snack food packaging machine products to avoid wastage.

Expert Insights: Common Mistakes to Avoid When Investing

Buying a commercial food packaging machine is a major capital expense; avoiding common pitfalls protects your ROI.

· Ignoring Future Growth: Buying a machine that barely meets today's demand leaves no room for scaling.

· Overlooking Material Costs: Some machines require proprietary, expensive films.

· Neglecting Support: Buying cheap imports without local support can halt production for weeks if a part breaks.

· Forgetting Compliance: Ensure the machine is CE or UL certified and meets FDA/USDA standards.

The Future of Food Packaging: Trends and Predictions for 2026+

The future of food packaging machines lies in hyper-automation and green technology, with a massive shift toward handling plastic-free materials. Reports indicate the pet food packaging machine market alone will reach over $12 billion by 2025, driving innovation in heavy-duty, recyclable pouch handling.

· Biodegradable Readiness: Machines adaptable to paper-based and compostable films.

· Hyper-Personalization: Digital printing integrated into lines for short-run, custom packaging.

· Supply Chain Resilience: automation reduces dependency on manual labor, shielding companies from labor shortages.

8 Fast-Growing Types of Popular Food Packaging and Processing Machines

Based on 2024-2025 market data, these categories show the highest adoption rates and technological advancement.

|

Machine Type |

Best For |

Approx. Cost Range (USD) |

Key Trend |

|

1. Vertical Form Fill Seal (VFFS) |

Snacks, Coffee, Powders |

$10,000 - $110,000+ |

High-speed motion control |

|

2. Flow Wrappers (HFFS) |

Bakery, Bars, Confectionery |

$20,000 - $150,000+ |

AI vision inspection |

|

3. Vacuum Packaging Machines |

Meat, Cheese, Frozen Food |

$300 - $70,000 |

Smart vacuum sensing |

|

4. Premade Pouch Fillers |

Pet Food, Premium Snacks |

$25,000 - $100,000+ |

Zipper/Resealable capability |

|

5. Tray Sealers (MAP) |

Ready Meals, Fresh Produce |

$15,000 - $80,000 |

Eco-friendly tray materials |

|

6. Multihead Weighers |

Granular Products, Mixed Snacks |

$15,000 - $60,000 |

AI load balancing |

|

7. Stick Pack Machines |

Single-serve Drink Mixes |

$15,000 - $90,000 |

Multi-lane high throughput |

|

8. Robotic Case Packers |

End-of-line Boxing |

$50,000 - $200,000+ |

Collaborative robots (Cobots) |

For a deeper dive into heavy-duty options, read our guide on food packaging machines for industrial use.

Frequently Asked Questions (FAQ)

What are the primary benefits of using a food packaging machine?

The primary benefits include drastically improved efficiency, enhanced hygiene by reducing human contact, consistent package quality, and extended product shelf life through technologies like vacuum sealing.

How do I determine the right type of food packaging machine for my product?

You must analyze your product's physical state (liquid, solid, powder), required shelf life, production speed, and packaging material. For instance, a frozen food packaging machine must handle cold environments, while a snack food packaging machine needs to handle delicate items gently.

What are the key differences between VFFS and HFFS machines?

A VFFS (Vertical Form Fill Seal) machine forms bags vertically and is best for loose items like chips or rice. An HFFS (Horizontal Form Fill Seal) machine wraps products horizontally and is ideal for solid, single items like candy bars or trays.

Can food packaging machines handle different types of food products and materials?

Yes, modern machines are highly versatile. Many feature quick-changeover parts to switch between bag sizes or materials, including new eco-friendly films, though you should verify compatibility with your manufacturer.

What maintenance is required for a food packaging machine?

Routine maintenance involves daily cleaning/sanitizing, weekly lubrication of moving parts, regular inspection of sealing jaws and cutting blades, and software updates for smart machines.

How much does a new food packaging machine typically cost?

Costs vary widely. A simple semi-automatic sealer might cost $1,000-$5,000. A high-speed commercial food packaging machine like a VFFS system typically ranges from $10,000 to over $100,000 depending on features and speed.

What role does automation play in modern food packaging?

Automation is critical for scaling production. It ensures precision weighing, reduces waste (giveaway), minimizes labor costs, and integrates with ERP systems for real-time production tracking.

Are there sustainable options available for food packaging machinery?

Yes, many manufacturers now offer machines specifically calibrated to run recyclable mono-material films, paper-based structures, and biodegradable plastics without compromising speed or seal integrity.

Conclusion

As food manufacturers prepare for 2026, investing in the right packaging and processing machines is no longer just about speed—it’s about precision, flexibility, and long-term efficiency. From high-speed VFFS systems to intelligent vacuum sealers, the fastest-growing equipment categories reflect a clear shift toward automation, data-driven control, and sustainable production. By understanding these trends and aligning equipment choices with product requirements and capacity goals, manufacturers can future-proof their production lines. With its strong expertise in weighing, packaging integration, and intelligent automation, Kenwei is well positioned to support food producers in adopting advanced solutions that improve accuracy, reduce waste, and stay competitive in a rapidly evolving market.

References

· Food Packaging Machines Market Size & Share Report – 2034

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

About Solution suggestions

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

The linear weigher is perfect for precise, quantitative weighing of powdery and small granular materials such as white sugar, salt, monosodium glutamate, chicken essence, milk powder, coffee, seasoning powder, and more. Available in up to 5 different specifications, this linear scale offers a maximum weighing speed of up to 70 bags per minute, making it the top choice for accurately weighing powdery materials in high-speed production environments.

The Kenwei JW-B22 Precision Food Packaging Machine with Single Head Bulk Linear Weigher is designed for heavy-duty weighing up to 50kg. It automates feeding, weighing, bag sewing, and output for maximum efficiency. Ideal for grains like corn, rice, soybeans, barley, and wheat, it ensures high accuracy and reliability for the food, chemical, and light industries, making it the top choice for bulk grain packaging.

The Kenwei JW-B26 Single Multihead Weigher Mixing and Packaging System offers fully automated operation, completing feeding, weighing, filling, date printing, and product output with high accuracy and speed. Ideal for granules, slices, irregular shapes, and mixed products like candy, nuts, snacks, pet food, and even small hardware. Its versatility and precision make it a perfect solution for diverse packaging needs.

Kenwei's JW-B2 Fully Automatic Twin Packaging Machine boasts 14-head multihead weighing for precise granule and snack food packaging. This high-speed automatic packaging machine offers efficient twin-packaging, maximizing your production output. Ideal for food manufacturers seeking enhanced speed and accuracy.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei