Multihead Weigher Buying Guide for Food Industry 2026

- Multihead Weigher Buying Guide for Food Industry 2026

- Why buy a multihead weigher for food production: meeting speed and accuracy demands

- Key features to evaluate when buying a multihead weigher

- Choosing multihead weigher capacity and speed: how to match line requirements

- Accuracy and consistency of multihead weighers: reduce giveaway and ensure compliance

- Hygienic design and CIP considerations when buying a multihead weigher

- Integration and automation: choosing a multihead weigher that fits your line

- Maintenance, spare parts, and service: ensuring uptime for your multihead weigher

- Cost considerations and ROI analysis when you plan to buy a multihead weigher

- Product handling and customization: tailoring a multihead weigher to your product

- Comparing multihead weighers, linear weighers, and combination weighers: which to buy?

- Selecting a supplier: why Kenwei is a strong option for your multihead weigher purchase

- Installation, commissioning and operator training when buying a multihead weigher

- Final checklist: questions to ask before you buy a multihead weigher

- FAQ – Frequently asked questions about buying a multihead weigher

- Contact us / View products — take the next step to buy a multihead weigher

- References and data sources

Multihead Weigher Buying Guide for Food Industry 2026

Why buy a multihead weigher for food production: meeting speed and accuracy demands

Multihead weighers have become the backbone of high-speed, high-accuracy portioning and primary packing lines in the food industry. If you are considering to buy a multihead weigher, your priorities are likely throughput, weight accuracy, product integrity, and line uptime. Modern multihead weighers combine many weigh heads (commonly 10–14 or more) with intelligent combinatorial algorithms to deliver target weights rapidly with minimal giveaway. This reduces product waste and increases yield — both critical for competitive food producers.

Key features to evaluate when buying a multihead weigher

When you evaluate multihead weighers, ensure the specification addresses these core features: number of heads (affects speed and combination possibilities), net weight range and increments, hopper and chute design for gentle product handling, speed (packs/min), touchscreen PLC interface, hygiene design (IP rating, easy-clean), servo vs. pneumatic vibratory feed systems, and compatibility with your upstream/downstream equipment (feeders, conveyors, vertical form-fill-seal (VFFS) machines, tray packers, etc.). These features directly impact yield, maintenance time, and total cost of ownership.

Choosing multihead weigher capacity and speed: how to match line requirements

Selecting the correct capacity and speed is essential to achieve the desired packs per minute (ppm) without sacrificing accuracy. Typical configurations include 10, 14, and 20-head machines; increasing head count improves the number of combination permutations and therefore can increase speed and accuracy for small target weights. Consider these practical rules:

- Target packs/min = (combinations per second) × cycle efficiency. Use vendor cycle charts to estimate.

- Small target weights (e.g., 5–50 g) often benefit from higher head counts (14–24 heads).

- Bulk products (nuts, chips) versus fragile products (cookies, biscuits) require different feed and chute designs.

Choosing the right capacity minimizes giveaway (product overfilling) and ensures the downstream packaging machine runs at rated speed.

Accuracy and consistency of multihead weighers: reduce giveaway and ensure compliance

Accuracy is the chief economic driver for buying a multihead weigher. Good multihead weighers maintain tight weight distribution by using fast, repeatable measurement and intelligent combination selection. When shopping, ask for verification data: typical sigma (standard deviation) at your target weight, average giveaway percentage, and capability index (Cpk) if available. For regulated markets, ensure the machine can meet local metrology and labeling rules — for example, EU and US regulations on net quantity labeling. Advanced machines offer dynamic correction and recipe storage to maintain accuracy across product runs.

Hygienic design and CIP considerations when buying a multihead weigher

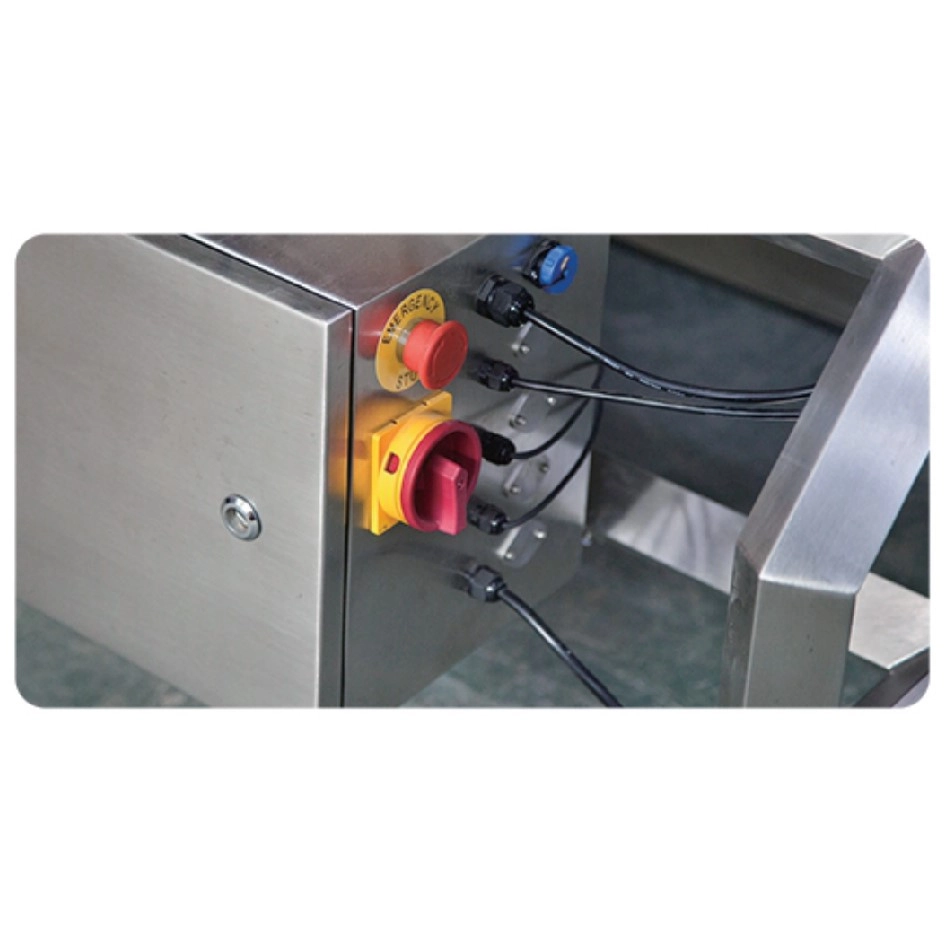

Food safety is non-negotiable. Ask whether the multihead weigher meets hygienic design principles: stainless steel 304/316 contact parts, sloped surfaces to avoid standing water, quick-release feed chutes and hoppers for cleaning, IP65 or higher for electrical enclosures, and washdown-capable components if you run wet-clean processes. For allergen control and rapid product changeovers, look for tool-less disassembly and smooth surfaces to minimize harborage. Compliance with food safety standards (e.g., ISO 22000, local regulations) should be demonstrable through documentation and factory practices.

Integration and automation: choosing a multihead weigher that fits your line

Modern production lines demand synchronized equipment. When evaluating multihead weighers, prioritize machines that offer standard communication protocols (Ethernet/IP, Profinet, Modbus) and easy recipe transfer. Integration features to check: line speed tracking, PLC I/O mapping, ability to work with upstream feeders (vibratory or belt) and downstream packers (VFFS, tray packers, form-fill machines), and support for Industry 4.0 data collection (production counts, weight distributions, reject rates). A weigher that provides real-time dashboards and remote diagnostics reduces troubleshooting time and supports continuous improvement.

Maintenance, spare parts, and service: ensuring uptime for your multihead weigher

Buying a multihead weigher is not just buying hardware; it's buying a service relationship. Evaluate the supplier’s spare parts availability, typical lead times, and technician training programs. Ask about preventive maintenance schedules, recommended spare-part kits (motors, sensors, belts), and whether the vendor offers remote support tools. Machines with modular components and widely available standard parts reduce downtime and lower long-term maintenance costs.

Cost considerations and ROI analysis when you plan to buy a multihead weigher

Cost is a major decision factor, but focus on total cost of ownership (TCO) rather than purchase price. TCO includes initial cost, installation, integration, maintenance, spare parts, energy consumption, and the opportunity cost from product giveaway and downtime. A simple ROI model includes:

| Item | Annual Cost (Example) |

|---|---|

| Machine capital cost (amortized) | $20,000 |

| Energy & consumables | $3,500 |

| Spares & maintenance | $6,000 |

| Product giveaway savings (annual) | -$35,000 |

| Net annual benefit | $5,500 |

Example numbers vary by product value and line output. High-value products or large-volume production lines justify faster, more accurate machines more quickly. Use vendor-supplied performance data and your product value to build an ROI case.

Product handling and customization: tailoring a multihead weigher to your product

Different food products demand specific handling: powders, snacks, frozen vegetables, fresh fruit, confectionery, and baked goods all have distinct flow and fragility characteristics. When you buy a multihead weigher, specify product characteristics so the supplier can suggest suitable feeder types, chute materials (UHMW, PTFE, or stainless steel), and special soft-drop or pillow conveyors for fragile items. Customizable recipes, adjustable vibration settings, and different hopper sizes are essential for efficient changeovers and consistent results across product families.

Comparing multihead weighers, linear weighers, and combination weighers: which to buy?

It helps to compare technologies before purchase. Below is a concise comparison table summarizing typical use-cases and strengths.

| Weigher Type | Best For | Speed | Accuracy | Typical Use Cases |

|---|---|---|---|---|

| Multihead weigher | Loose, variable-size products | High (50–300 ppm depending on product/setup) | High (low giveaway) | Snacks, nuts, frozen vegetables, candy, pet food |

| Linear weigher | High-speed, steady-flow products | Very high (>300 ppm) | Moderate to high | Powders, grains, small solids |

| Combination weigher | Integrated systems for specific pack types | Varies | High | Pre-made trays, dose-sensitive applications |

Source data vary with product and configuration; consult vendors for machine-specific performance charts.

Selecting a supplier: why Kenwei is a strong option for your multihead weigher purchase

Choosing the right manufacturer is as important as the machine. Kenwei is a powerful manufacturer of multi-head weighers. We are committed to the development and manufacturing of metal detectors, multi-head weighers, linear weighers, and check weighers. Our machines are characterized by high speed and high precision. We also provide our customers with one-stop automated weighing and packaging solutions to meet our customers’ customization requirements. Guangdong Kenwei is located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province. The company is equipped with an automated weighing and packaging system and has comprehensive capabilities in design and development, manufacturing, marketing, installation and commissioning, technical training, and after-sales service. It has established a good brand image and a reputation for thoughtful and fast service in the packaging machinery industry.

Kenwei’s vision is to become the world's leading weighing packing machine manufacturer. Core products and strengths include:

- Check Weigher — high-speed in-line weight verification and grading.

- Multihead Weigher Packing Machine — flexible, accurate portioning for a wide product range.

- Linear Weigher — ultra-high-speed dosing for powders and small solids.

- Metal Detector — integrated food safety control for critical control points.

- Packing Machine and Counting Machine — end-of-line solutions to match weighers.

- Combination Weigher — tailored solutions combining weighing and counting for specialty packs.

- Food Packaging Machinery — one-stop solutions including VFFS, tray sealers, and automated lines.

Kenwei emphasizes high precision, fast cycle times, and customized design. Their onsite capabilities include R&D, automated manufacturing, and full-service support — from commissioning to technical training and after-sales care. For more details, visit Kenwei’s official site: https://www.kenweigroup.com/.

Installation, commissioning and operator training when buying a multihead weigher

Proper commissioning and operator training are essential to realize the machine's promised performance. Ensure the vendor provides installation support: mechanical alignment, electrical hookup, PLC integration, product and line balancing, and initial acceptance testing with your product. Operator training should cover daily cleaning, changeover procedures, basic troubleshooting, and a preventive maintenance checklist. Consider yearly refresher training and documentation in your local language for consistency.

Final checklist: questions to ask before you buy a multihead weigher

Before you place an order, confirm these items with your supplier:

- Performance test data with your actual product(s) — sigma, giveaway %, packs/min.

- Hygienic design and cleanability verification (materials, IP rating).

- Integration options and communication protocols for your line PLC.

- Warranty, spare parts list, lead times, and service coverage.

- Training, commissioning scope, and acceptance criteria.

- Energy consumption and recommended preventive maintenance plan.

FAQ – Frequently asked questions about buying a multihead weigher

Q: How do I know how many heads I need on a multihead weigher?

A: Head count depends on target weight range, product variability, and required speed. Smaller target weights and fragile products typically benefit from more heads (14–24) for better combination accuracy. Ask vendors for tests on your product to confirm.

Q: Can a multihead weigher handle both frozen and fresh products?

A: Yes, but frozen products require low-temperature components and often different chute materials to prevent sticking. Discuss temperature-rated options and anti-freeze measures with suppliers.

Q: What cleaning features should I insist on?

A: Look for quick-release hoppers, sloped surfaces, minimal crevices, and food-grade stainless steel. IP65 or higher electrical cabinets and washdown-capable drives are important if you plan to wet-clean the line.

Q: How long is the typical payback period for a multihead weigher?

A: Payback varies widely based on product value and line utilization. For high-value products and 24/7 operations, payback can be under 18 months. Use a vendor-provided giveaway reduction estimate to model ROI accurately.

Q: Are remote diagnostics and Industry 4.0 features common?

A: Increasingly yes. Many new weighers support data export, remote access, and integration with MES systems to enable predictive maintenance and OEE monitoring.

Contact us / View products — take the next step to buy a multihead weigher

If you’re ready to buy a multihead weigher or want a line evaluation, contact Kenwei for consultation, product demonstrations, and site trials. Kenwei offers tailored proposals, on-site testing with your product, and turn-key automated weighing and packaging solutions. Visit https://www.kenweigroup.com/ to view product lines or request a quote and technical consultation.

References and data sources

Sources used for market context and standards referenced in this guide:

- Grand View Research — Packaging Machinery Market reports (market trends and drivers).

- Statista — Food Packaging industry statistics and growth indicators.

- International Organization of Legal Metrology (OIML) — recommendations for weighing instruments and verification practices.

- ISO 22000 — Food safety management systems (general hygienic design principles).

- Vendor technical brochures and machine acceptance test data (industry best practices).

G5020 Food Metal Detector: Ensuring Precision Rejecting Defects

Choosing the Right Metal Detector for Food Industry G5020 Guide

What are the application scenarios of powder packaging machine?

HACCP and Metal Detector Compliance for Food Manufacturers

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

16 Head Three Layer Multihead Weigher for Granular and Irregular Materials

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei