China’s Food Packaging Industry: Growth Trends, Innovations, and Automation Solutions

Driven by rising urban demand and retail growth, China’s food packaging industry is booming. This article explores its development status, emerging trends like smart and green packaging, and how Kenwei’s intelligent machinery enhances efficiency and economic returns for food manufacturers.

With China’s economic development, technological innovation, and industry expansion, the food packaging sector has seen consistent and rapid growth. Urbanization and the rise of modern retail have driven higher demand for packaged foods, spurring an increase in both packaging production and technological sophistication.

According to global market research, the food packaging market is projected to reach USD 606.3 billion by 2026, with a compound annual growth rate (CAGR) of 5.6%. China's packaging equipment market alone was valued at 16.85 billion yuan in 2021, growing at a CAGR of 10.15%—a clear indication of the industry's robust momentum.

Definition and Classification of the Food Packaging Industry

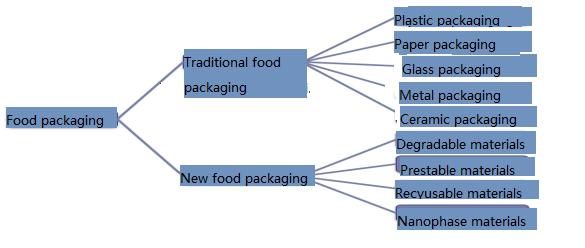

Food packaging plays a crucial role in protecting food from external physical, chemical, and biological factors, while also preserving quality and extending shelf life. Based on material type, food packaging can be classified into:

-

Traditional packaging (plastic, paper, glass, metal)

-

Innovative packaging (biodegradable, intelligent, and active materials)

- Main types of food packaging

Current Development Status of the Food Packaging Industry

As national income rises and per capita consumption increases, demand for food and beverages in China continues to expand. According to the National Bureau of Statistics:

-

In 2019, the food industry’s operating income reached ¥9.2 trillion, up 45% YoY.

-

Total profits hit ¥669.7 billion, up 6.8% YoY.

The food industry’s explosive growth has significantly fueled the packaging sector, creating strong market demand and opportunities for technological advancement.

Total operating income and profits of Chinese food enterprises from 2013 to 2019

Future Trends in the Food Packaging Industry

1. Aesthetic-Driven ("Appearance-Level") Packaging

As younger generations dominate the consumer market, packaging that is visually appealing has become a key driver of purchase decisions.

-

Eye-catching designs, custom branding, and limited-edition collaborations appeal to Gen Z and millennial buyers.

-

E-commerce platforms like JD.com require durable, standardized, pre-planned packaging to meet logistics needs—further shaping packaging formats.

2. Intelligent and Active Packaging

Smart packaging is transforming food safety and quality control.

-

Intelligent packaging can monitor freshness, temperature, and expiration.

-

Active packaging interacts with food to extend shelf life or enhance protection.

These technologies are becoming essential elements of next-generation food packaging design.

3. Eco-Friendly and Diverse Packaging Materials

Environmental sustainability is driving material innovation.

-

Biodegradable packaging made from natural polymers is gaining traction.

-

Recycled and recyclable materials are being prioritized to reduce pollution.

-

Packaging machinery is advancing with high precision and automation to support mass production using eco-materials.

- Analysis of the characteristics of active packaging and intelligent packaging

-

active packaging

intelligent packaging Way Add active agents (such as gas absorbers, releases, antibiotics, antioxidants, etc.) The environment and food freshness are monitored using the unique structural or material characteristics of the packaging material itself. Purpose Ensure and improve food quality and extend the shelf life Monitor whether food is fresh or whether the packaging is eligible for storage. Type Oxygen adsorption,carbon dioxide adsorption/release type,ethylene adsorption/release,antibacterial, moderate regulation,and temperature regulation type Time-temperature,oxygen,seal-leak,freshness/maturity Advantage Extend the shelf life to maintain or improve food quality Indicate whether the food is fresh during the shelf life Weakness Active substances migrate in food products, creating safety problems Cannot package and maintain the quality of the food

Kenwei’s Role in the Smart Packaging Revolution

Guangdong Kenwei Intellectualized Machinery Co., Ltd. is a global leader in intelligent weighing and packaging solutions. Kenwei offers:

-

Weighing equipment: Multihead weighers, linear weighers

-

Inspection systems: Checkweighers, metal detectors

-

Packaging lines: Fully automated production systems

Kenwei systems are compatible with a wide variety of food types—including candies, snacks, frozen food, pet food, and more.

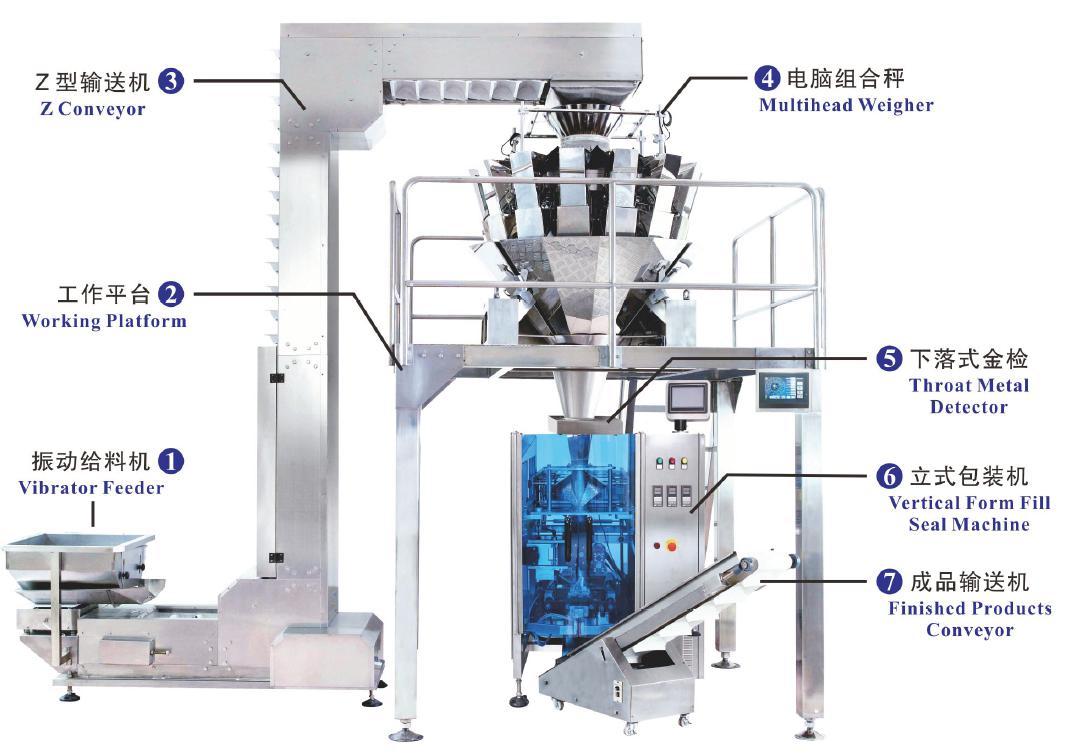

Their standard vertical weighing and packaging system includes:

-

Vibratory feeder

-

Z-type conveyor

-

Multihead combination scale

-

Metal detector

-

Vertical form-fill-seal machine

-

Output conveyor

Key Features and Benefits:

-

High measurement accuracy

-

Fast packaging speed

-

Compatibility with diverse packaging formats (e.g. pillow bags, gusset bags, quad seal bags)

-

-

Enhanced production efficiency and economic benefits

Conclusion

As China's food packaging industry evolves, smart technology, green materials, and aesthetic appeal are shaping the future. Kenwei’s advanced automation systems empower food manufacturers to meet market demands with efficiency, precision, and sustainability—supporting growth in a competitive global landscape.

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

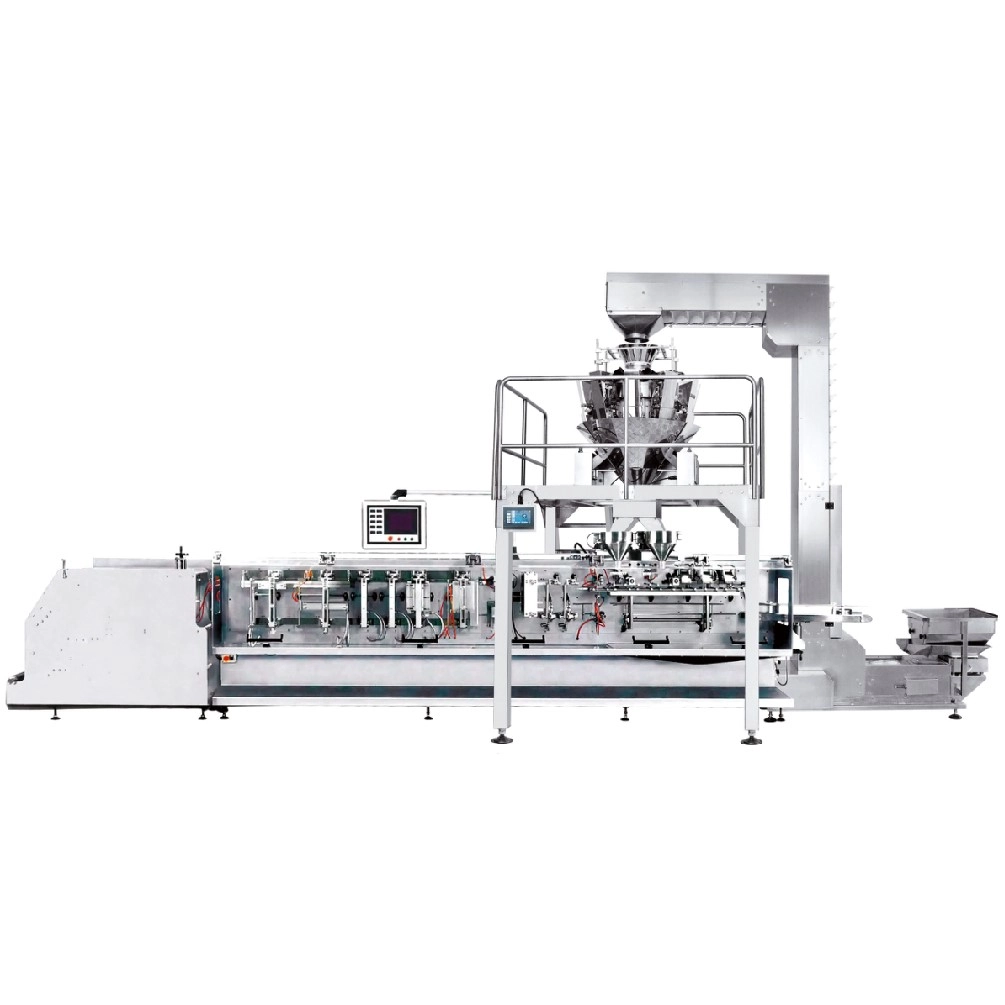

This fully automatic box-type weighing and packing machine is designed for high-precision, high-efficiency packaging of snack foods, puffed products, and granular materials. The system integrates an automatic box dropper, inclined conveyor, multihead weigher, filling and labeling units, ensuring seamless feeding, weighing, filling, printing, and labeling. Ideal for candy, nuts, seeds, jelly, and more. Customizable to meet diverse production needs.

The system consists of a vibrating feeder, a Z-type conveyor, a 14-head combination scale, a material diverter, an automatic cup drop device, a cup mold conveyor, a capping machine and a finished product conveying device. It has high-precision filling capabilities and is suitable for a variety of mold cup combinations. It can realize fully automatic operations of feeding, weighing, filling, bag making, printing and finished product output, and is suitable for a wide range of materials with high production efficiency.

The JW-B7 Economical Linear Weighing and Vertical Packaging Machine is ideal for packaging small granules and powder materials such as sugar, salt, rice, sesame, milk powder, coffee, and seasoning powder. This compact, cost-effective system automates feeding, weighing, filling, and bagging with date printing and output. It reduces labor costs, enhances efficiency, and is perfect for businesses with moderate speed requirements.

The Kenwei Economic Premade Pouch Weighing and Packing Machine JW-B15 offers fully automatic feeding, weighing, filling, date printing, and output. With high accuracy, speed, and space-saving design, it’s ideal for small 3-side or 4-side seal bags. Suitable for granules, slices, irregular shapes like candy, nuts, pet food, and small hardware. A cost-effective solution for precise, efficient packaging.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei