China's Packaging Machinery Industry: Rising Global Competitiveness Driven by Innovation and Demand

- 1. Steady Growth in Packaging Equipment Production

- 2. Industrial Upgrading and Challenges

- 3. Rising Output of Special Packaging Equipment

- 4. Rapid Growth in Packaging Machinery Exports

- 5. Market Size and Industrial Landscape

- 6. Future Development Trends: Toward Multi-Functional, Smart & Green Packaging

- ✅ 1) Multi-Purpose and High Quality

- ✅ 2) High Efficiency and Intelligence

- ✅ 3) Green and Sustainable Production

- Conclusion

China's packaging machinery industry has seen steady growth driven by rising demand from food, pharmaceuticals, and consumer goods sectors. With increased automation, exports, and industrial upgrading, it is becoming a global leader in intelligent, efficient, and green packaging equipment.

1. Steady Growth in Packaging Equipment Production

China’s packaging machinery industry, once heavily reliant on imports, has rapidly emerged as one of the top-performing sectors in the machinery industry. Packaging machinery refers to equipment that automates processes such as weighing, filling, sealing, labeling, palletizing, and more—essential for improving production efficiency and reducing labor costs.

As industrialization advances, packaging has become a crucial final step in the manufacturing process. Automation in packaging not only ensures product quality and safety but also enhances brand competitiveness through better presentation and compliance with hygiene standards.

Key Driving Factors:

-

Consumer demand for FMCG, food, beverages, pharmaceuticals, and electronics

-

Increased digitalization and smart manufacturing upgrades

-

Growing preference for automated, intelligent packaging lines

China’s packaging machinery is now shifting towards intelligent production, where automation and smart control systems play central roles in improving quality and output.

2. Industrial Upgrading and Challenges

Despite strong growth, the industry still faces structural challenges:

-

Fragmentation: A large number of small and medium-sized enterprises (SMEs) dominate the market. Many lack R&D capabilities and fail to scale.

-

Short product cycles: Nearly 15% of companies exit and another 15% enter the industry annually, showing both high churn and opportunity.

-

Innovation pressure: While automation levels exceed 50%, more breakthroughs are needed in smart manufacturing, especially among domestic players.

Government policies such as “Made in China 2025” have accelerated intelligent manufacturing. Enterprises are increasingly adopting robotics, digital sensors, and smart software to enhance packaging efficiency and reduce human dependency.

3. Rising Output of Special Packaging Equipment

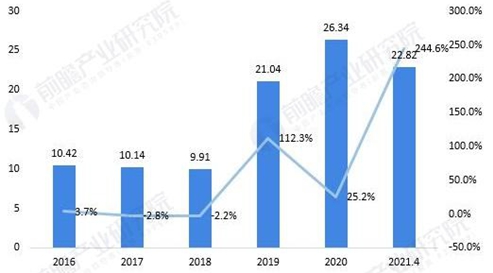

The output of specialized packaging equipment has surged in recent years:

-

In 2020, China produced 263,400 units, a year-on-year increase of 25.2%

-

By April 2021, production reached 228,200 units, an impressive 244.6% increase YoY

This growth reflects increasing demand from industries like food, pharmaceuticals, and daily chemicals, where product safety, speed, and precision are vital.

Production and growth of special packaging equipment in China from 2016 to 2021

(Unit: ten thousand units,%)

4. Rapid Growth in Packaging Machinery Exports

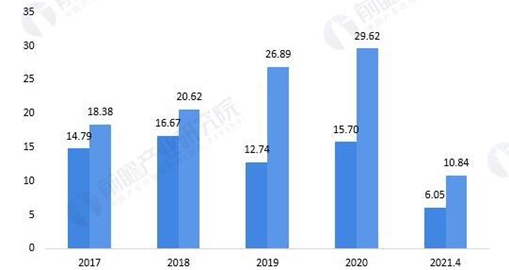

China’s packaging machinery has transitioned from a major importer to a leading exporter:

-

In 2020, export volume reached 14.27 million units, far surpassing imports of 145,800 units

-

Export value reached $2.962 billion, while imports were $1.570 billion

China’s packaging machinery is gaining ground globally, with growing demand in Asia-Pacific, Africa, and South America, thanks to its cost-effectiveness, increasing quality, and customization capabilities.

Import and export quantity of packaging machinery in China from2017-2021 (unit: ten thousand units)

Import and export amount of packaging machinery in China from 2017 to 2021(Unit: the US $100 million)

5. Market Size and Industrial Landscape

According to the China Machinery Industry Yearbook 2019:

-

In 2018, 319 companies above designated size generated revenue of ¥31.046 billion

-

Estimated market size in 2020: ¥34.6 billion

As a supporting industry to sectors like food, pharma, cosmetics, electronics, and logistics, packaging machinery benefits directly from broader economic development. However, competition is intensifying, both domestically and internationally.

Main business income of enterprises above the designated size of packaging special equipment manufacturing industry in China from 2015 to 2020 (unit: 100 million yuan)

6. Future Development Trends: Toward Multi-Functional, Smart & Green Packaging

To meet changing market and regulatory demands, the future of China’s packaging machinery lies in three core areas:

✅ 1) Multi-Purpose and High Quality

-

Equipment must handle diverse packaging forms, sizes, and materials

-

Demand for customizable, modular machines that support rapid production line shifts

✅ 2) High Efficiency and Intelligence

-

Integrating AI, motion control, vision inspection, and automation

-

Development of fully automatic, unmanned, integrated packaging lines

-

Increased emphasis on precision, traceability, and real-time monitoring

✅ 3) Green and Sustainable Production

-

Focus on energy-saving designs, recyclable packaging materials, and low-emission operations

-

Aligning with global trends in eco-conscious manufacturing and ESG compliance

Conclusion

China’s packaging machinery industry stands at the crossroads of transformation and global leadership. Fueled by industrial upgrades, rising exports, and smart manufacturing, it is poised for continued growth and innovation.

To stay competitive, enterprises must invest in R&D, enhance automation and intelligence, and align with the future demands of multi-functional, eco-friendly, and high-efficiency packaging solutions.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei