The Rise of China’s Packaging Machinery Industry: Trends, Drivers, and Market Outlook

- China’s Packaging Machinery Industry is Booming

- From Late Start to Global Competitor

- Explosive Growth in Production Output

- Common Packaging Machinery Types in Demand

- Key Growth Drivers

- Food & Beverage: The Core Growth Engine

- Domestic Players on the Rise

- A Shorter Equipment Lifecycle Means Faster Innovation

- Looking Ahead: Toward Smart, Efficient, High-Speed Systems

China’s packaging machinery industry is rapidly evolving, driven by rising domestic demand, automation, and consumer product innovation. With high growth in exports and production, manufacturers like Guangdong Kenwei are leading the way in intelligent, high-speed solutions for food, beverage, and pharmaceuticals.

China’s Packaging Machinery Industry is Booming

In daily life, packaging is essential and ever-present. Over the past 30 years, China’s packaging machinery industry has grown from humble beginnings into one of the top ten sectors within the country’s machinery landscape. As the world’s largest exporter of consumer goods, China’s packaging equipment sector is now recognized globally for its rapid growth and immense potential.

From Late Start to Global Competitor

Although China’s packaging machinery industry started relatively late, it has caught up swiftly. Today, the country's technological capabilities have reached mid-to-high levels globally, and more Chinese companies are stepping into international markets.

According to the General Administration of Customs, between January and September 2020, China exported 9.39 million packaging machinery units—up 48.1% year-on-year. The export value reached USD 2.04 billion, a 0.4% increase over the previous year.

Explosive Growth in Production Output

Data from the National Bureau of Statistics shows robust growth in production. In 2020, China produced 263,400 units of specialized packaging equipment, a 25.2% year-on-year increase. In just the first four months of 2021, output reached 228,200 units—up 159.1% year-on-year, reflecting a surging domestic demand and improved manufacturing capability.

Common Packaging Machinery Types in Demand

The most commonly used equipment includes:

-

Filling machines – for liquids like beverages, oils, and dairy

-

Bagging machines – for powders, granules, and fluids

-

Wrapping machines – for large, rigid products

-

Labeling machines – for product identification and compliance

-

Case packers & unpackers – for secondary packaging, improving logistics

Driven by fast-moving consumer goods (FMCG) like food, beverages, and pharmaceuticals, these machines are seeing consistent demand growth.

Key Growth Drivers

Industry analysts identify three main growth avenues for packaging machinery:

-

Upgrading existing equipment to improve speed and automation

-

Product innovation driving structural demand (e.g., canned beverages, ready-to-drink milk)

-

Mechanization and digitization of traditional sectors like liquor production

Other favorable factors include rising labor costs, large-scale production requirements, and consumer demand for safer, smarter packaging.

Food & Beverage: The Core Growth Engine

Globally, food and beverage remain the two largest sectors driving packaging machinery demand—accounting for 56% of total market usage. According to The Freedonia Group, the global packaging equipment market will reach USD 60.4 billion by 2023, with 55% of new demand coming from Asia-Pacific.

In China, the food packaging machinery segment alone generated CNY 81.08 billion in 2020, a 9.28% increase over 2019. However, 13.37% of equipment was still imported, with brands like Tetra Pak, Krones, Bosch, and KHS dominating the high-end market.

Domestic Players on the Rise

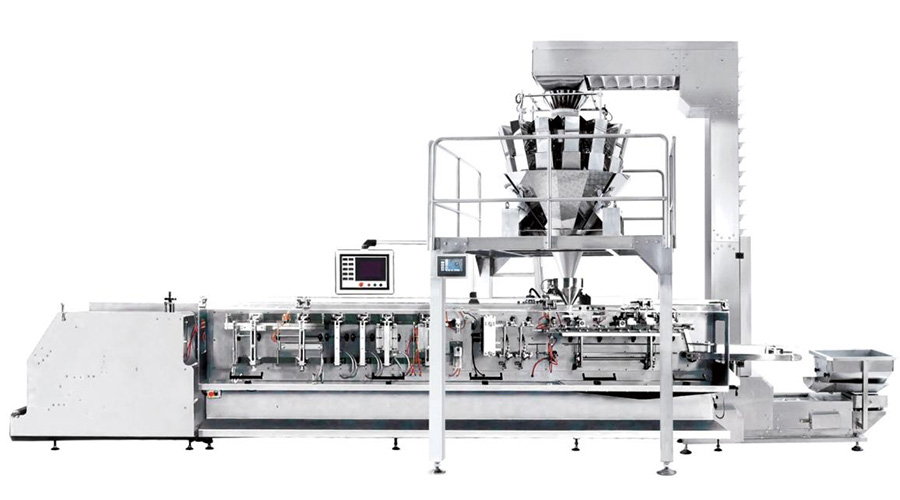

While there's still a technological gap, domestic leaders like Guangdong Kenwei Intellectualized Machinery Co., Ltd. are making strides. Known for its high-precision combination weighers and intelligent solutions, Kenwei produces up to 7,500 units annually, with applications across food, medicine, chemicals, and more.

Other emerging brands like Youngsun, Lehui International, and Zhongya are also gaining market share and recognition in both domestic and global markets.

A Shorter Equipment Lifecycle Means Faster Innovation

Unlike traditional machinery, packaging equipment has a shorter effective lifecycle—averaging 8 years. Rapid product changes and expansion in FMCG sectors force manufacturers to upgrade or replace equipment frequently, accelerating industry development.

Looking Ahead: Toward Smart, Efficient, High-Speed Systems

With an annual growth rate projected at 4.5%, China’s packaging machinery industry is shifting toward:

-

High precision

-

Intelligent automation

-

Digital transformation

To remain competitive, manufacturers must invest in R&D, improve technological capacity, and tailor solutions to evolving market demands.

Conclusion:

As China accelerates its transformation into a global manufacturing powerhouse, its packaging machinery industry is positioned for sustained and dynamic growth. Companies like Kenwei exemplify the shift toward high-end, intelligent equipment—driving the future of packaging forward.

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei