New Opportunities in Prefabricated Dishes Packaging Industry

- The Rise of Prefabricated Dishes

- Packaging Requirements for Prefabricated Dishes

- New Trends in Food Packaging Technology

- 1. Vacuum Packaging for Freshness Preservation

- 2. Coated Iron Packaging – A New Track for Prefabricated Foods

- 3. Multifunctional & Flexible Packaging Equipment

- Kenwei’s Smart Packaging Solutions

The prefabricated dishes industry is rapidly expanding in China, opening up new opportunities in the trillion-dollar food sector. As consumer demand grows, innovative packaging technologies such as vacuum packaging, coated iron solutions, and automated weighing systems are playing a critical role in extending shelf life, ensuring food safety, and improving convenience.

The Rise of Prefabricated Dishes

With the momentum from the 20th National Congress of the Communist Party of China and national policies encouraging consumer growth, the prefabricated dishes industry has entered a new stage. Since 2020, prefabricated dishes have become a fast-growing sector. Today, China has more than 64,000 enterprises in this field, and financing in 2022 alone exceeded 700 million yuan.

At the beginning of 2023, the No. 1 central document officially included prefabricated dishes in its development goals, emphasizing standardization and industry growth.

Packaging Requirements for Prefabricated Dishes

-

Better Storage Performance

From vacuum packaging and skin packaging to modified atmosphere and canned packaging, food freshness and preservation are essential. Prefabricated dishes require packaging that ensures long-term stability while meeting consumer needs. -

Convenient Consumption

Consumers prefer ready-to-cook, ready-to-heat, and ready-to-eat meals. Packaging must prioritize convenience and portability to match evolving lifestyles. -

Smarter Packaging Design

Innovative packaging is no longer just about appearance—it must integrate consumer insights, functional design, and scenario-based applications to enhance user experience.

New Trends in Food Packaging Technology

1. Vacuum Packaging for Freshness Preservation

Vacuum packaging remains a leading method to extend shelf life. Whether using vacuum bag packaging or vacuum box packaging, the technology removes oxygen to prevent food spoilage. Popular vacuum packaging machines include:

-

Double chamber vacuum packaging machines

-

Rolling vacuum packaging machines

-

Stretch film vacuum packaging machines

Vacuum box packaging is particularly suitable for ready-to-eat products such as cold meat, crayfish, duck neck, and Liangpi.

2. Coated Iron Packaging – A New Track for Prefabricated Foods

Coated iron offers excellent adaptability for most food categories. With superior preservation properties, it can extend shelf life up to one year without additives. Its eco-friendly qualities, thermal conductivity, airtightness, and durability make it a promising packaging solution for prefabricated dishes.

3. Multifunctional & Flexible Packaging Equipment

To meet diverse market demands, packaging machines are evolving toward single-machine multifunctionality and modular flexibility. For example, modular vacuum packaging machines allow manufacturers to adapt quickly to new processes while reducing equipment costs.

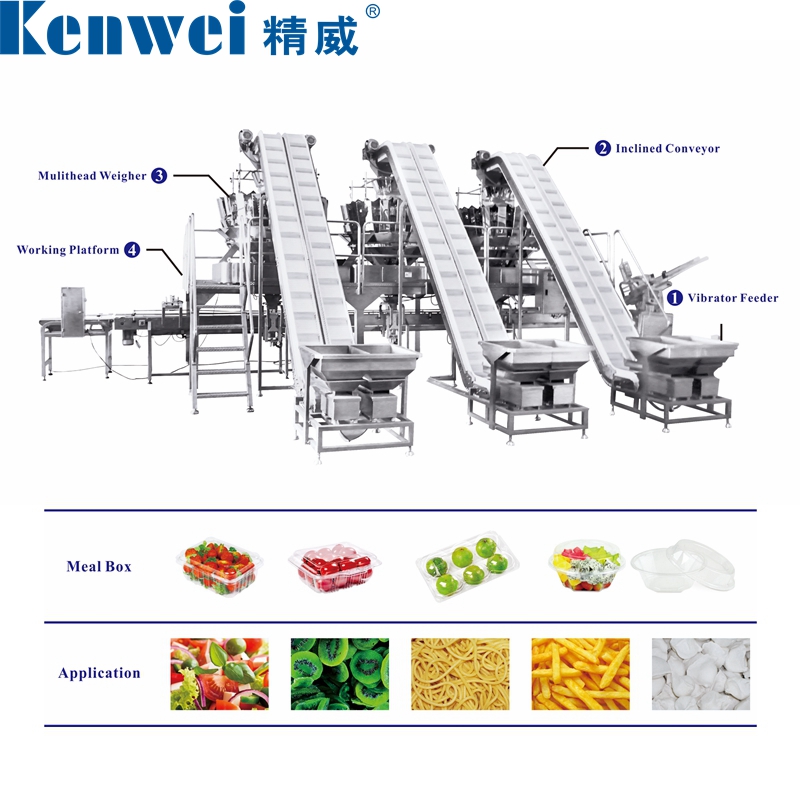

Kenwei’s Smart Packaging Solutions

Guangdong Kenwei Intellectualized Machinery Co., Ltd. is dedicated to developing automated weighing and packaging systems that combine precision, efficiency, and reliability. With cutting-edge equipment, Kenwei helps businesses achieve smarter and more aesthetic packaging solutions.

Recommended Products:

-

Box-type packaging and weighing system

-

Standard vertical weighing and packaging system

-

Rotary packaging and weighing system

-

Horizontal packaging and weighing system

About products customization

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

About Solution suggestions

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

About Product choice

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About After Sales Support

How about the after-sales service?

Warranty :2 years

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei