top multihead weigher maintenance tips 2026

- Top Multihead Weigher Maintenance Tips 2026

- Why regular maintenance for your multihead weigher matters

- Create a preventive maintenance schedule (: multihead weigher service)

- Daily checks and hygiene (: multihead weigher cleaning)

- Cleaning best practices

- Weekly and monthly mechanical maintenance (: multihead weigher maintenance tips)

- Calibration and accuracy checks (: multihead weigher calibration)

- Spare parts and wear consumables strategy (: multihead weigher spare parts)

- Use condition monitoring and predictive maintenance (: multihead weigher predictive maintenance)

- Electrical, controls, and software maintenance (: multihead weigher service contract)

- Product changeovers and allergen control (: multihead weigher cleaning)

- Operator and maintenance staff training (: multihead weigher training)

- When to call the OEM or a certified service partner (: multihead weigher support)

- Kenwei: manufacturer profile and how we support maintenance

- How Kenwei helps customers minimize downtime

- Kenwei main products and competitive strengths

- Practical checklist: 10 quick maintenance actions you can implement today (: multihead weigher checklist)

- FAQ (Frequently Asked Questions)

- Q: How often should I calibrate a multihead weigher?

- Q: What are the most common causes of weighing inaccuracy?

- Q: Can I clean a multihead weigher with high-pressure water?

- Q: How can predictive maintenance help my weigher line?

- Q: What spare parts should I always keep on-site?

- Q: When should I contact Kenwei for service?

- Contact us / View products (CTA)

- Sources

Top Multihead Weigher Maintenance Tips 2026

Why regular maintenance for your multihead weigher matters

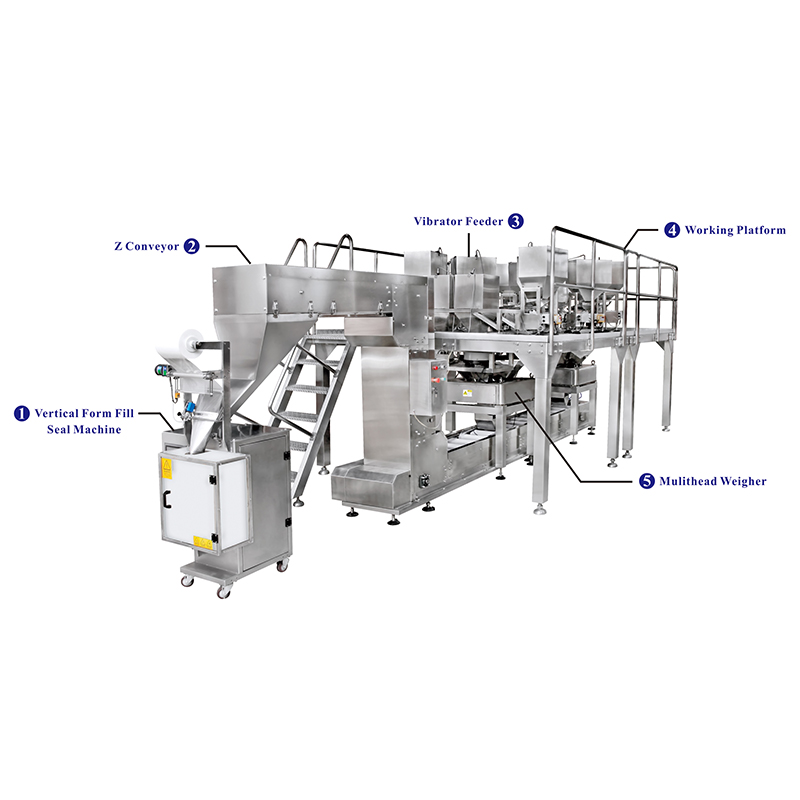

Multihead weighers (also called combination weighers) are precision machines that combine high speed with fine accuracy to dose products for packing. Proper maintenance keeps accuracy within tolerance, reduces downtime, improves product quality, and lowers total cost of ownership. In 2026, demands for higher throughput, stricter food safety rules, and Industry 4.0 connectivity make disciplined maintenance not optional — it’s a competitive requirement.

Create a preventive maintenance schedule (: multihead weigher service)

A written preventive maintenance (PM) schedule is the backbone of reliable multihead weigher performance. Your PM plan should be tiered by frequency (daily, weekly, monthly, quarterly, annual) and by role (operator, maintenance tech, external service). Include checklists, acceptable tolerances, and troubleshooting steps so tasks are repeatable and auditable.

- Daily: visual checks, hygiene cleaning, software backup — operator responsibility.

- Weekly: mechanical checks, belt/hopper inspection, simple calibrations — operator or line tech.

- Monthly: loadcell verification, vibration checks, tighten fasteners — maintenance team.

- Quarterly: electrical cabinet inspection, sensor recalibration, spare-parts reorder review.

- Annual: full inspection, preventative replacements (wear parts), firmware updates, and performance validation with certified weights.

Document every action (who, when, what result). Documentation improves traceability and helps during audits or warranty claims.

Daily checks and hygiene (: multihead weigher cleaning)

Daily checks keep small problems from escalating. A short operator checklist takes 5–10 minutes and returns large reliability gains.

- Clean product contact surfaces after each product run or shift to prevent cross-contamination and buildup.

- Inspect for loose or damaged hoppers, feed trays, and agitators. Minor damage causes major weighing errors.

- Verify that the machine starts and runs through a test cycle (no jams, normal sound, no error codes).

- Check that reject mechanisms and conveyors operate smoothly and that reject pathways are clear.

- Record basic performance metrics: average fill weight, rejects per hour, cycle time.

Cleaning best practices

Use food-safe cleaning agents appropriate for product type. Avoid high-pressure washing on sensitive electronics and loadcells. When disassembling for deep cleaning, mark parts and bolts to ensure correct reassembly. Allow surfaces to dry completely before restarting. Use a cleaning validation step for allergen-sensitive lines.

Weekly and monthly mechanical maintenance (: multihead weigher maintenance tips)

Perform more detailed inspections weekly and monthly to detect wear early.

- Check agitator blades and flighting for wear or deformation.

- Inspect vibrating feeders and pan for uneven wear or loose mounts.

- Verify belt tensions and replace belts showing cracking or fraying.

- Lubricate bearings and linkage points per OEM recommendations; avoid over-lubrication that attracts debris.

- Examine loadcells for foreign material, corrosion, or mechanical impact.

Calibration and accuracy checks (: multihead weigher calibration)

Calibration maintains weighing accuracy and compliance. Use certified calibration weights and follow a documented procedure. Calibration checks should be done:

- After any mechanical service involving hoppers or loadcells.

- When product characteristics change (density, particle size, moisture).

- On a scheduled basis (monthly or quarterly) depending on line criticality.

Standard calibration steps:

- Warm up the machine to operating temperature.

- Run an empty-bucket zero check on all weigh hoppers.

- Apply certified weights to single hoppers and combination outputs; compare the displayed mass to reference weight.

- Adjust software compensation factors as necessary and record the results.

Keep calibration certificates and logs for auditing and quality control.

Spare parts and wear consumables strategy (: multihead weigher spare parts)

Planned spare-part inventory avoids production stoppages. Maintain an ABC list: critical spares (A), important spares (B), long-lead or infrequent spares (C). Typical A-items include loadcells, vibration motors, PLC modules, and key sensors.

| Component | Typical lifespan | Recommended replacement interval | Notes / Source |

|---|---|---|---|

| Loadcells | 5–10 years | 5 years (or upon calibration drift) | Depends on environment & shock exposure (industry averages) |

| Vibration motors | 3–8 years | 3 years (inspect bearings annually) | High-cycle applications reduce life |

| Belts / Seals | 1–3 years | Replace as wear appears; plan yearly | Subject to product abrasion and cleaning chemicals |

| Sensors / Photoeyes | 2–5 years | Replace on failure; keep 1 spare per major line | Contamination and misalignment are common causes of failure |

Table sources: industry maintenance surveys and OEM recommendations; inspect in-line for variations based on product and environment.

Use condition monitoring and predictive maintenance (: multihead weigher predictive maintenance)

In 2026, predictive maintenance leverage is higher and more affordable. Integrate vibration sensors, temperature sensors on motors, and cycle counters to identify anomalies before failure. Add these practices:

- Trend vibration and temperature data; set alert thresholds.

- Use IoT gateways to push anonymized performance data to cloud analytics for trend analysis.

- Schedule service when indicators show early wear rather than waiting for breakdowns.

Predictive maintenance reduces unplanned downtime and can lower spare-part stock needs. For larger operations, consider a remote support contract with the OEM for real-time diagnostics.

Electrical, controls, and software maintenance (: multihead weigher service contract)

Electronics are as important as mechanical parts. Regular tasks include:

- Inspect control cabinets for dust, condensation, and loose wiring.

- Back up PLC and HMI programs after any change; maintain version control.

- Apply firmware updates only after validation on a test unit to prevent unexpected behavior.

- Monitor grounding and EMI sources; poor grounding can produce noisy loadcell signals and inaccurate fills.

Product changeovers and allergen control (: multihead weigher cleaning)

Proper procedures for changeovers reduce downtime and contamination risk. Use quick-disassembly parts where possible. Key steps:

- Define a standard changeover procedure with time targets and roles.

- Use color-coded tools and parts for allergen lines.

- Validate cleaning with swabs or ATP tests for sensitive lines.

Operator and maintenance staff training (: multihead weigher training)

Skilled operators prevent many failures. Provide role-based training: operators for daily checks and basic troubleshooting, maintenance techs for deeper mechanical/electrical tasks, and engineers for calibration and control changes. Use competency assessments and refresher training annually.

When to call the OEM or a certified service partner (: multihead weigher support)

Call OEM support if you observe:

- Persistent calibration drift despite corrective actions.

- Repeated electrical faults or PLC crashes after firmware updates.

- Mechanical damage that affects structural alignment or loadcell mounting.

- Complex software errors or recipe corruption.

Ongoing support agreements with an OEM or certified partner often include remote diagnostics, priority spare-part access, and annual inspections — valuable for high-volume lines.

Kenwei: manufacturer profile and how we support maintenance

Kenwei is a powerful manufacturer of multi-head weighers. We are committed to the development and manufacturing of metal detectors, multi-head weighers, linear weighers, and check weighers. Our machines are characterized by high speed and high precision. We also provide our customers with one-stop automated weighing and packaging solutions to meet our customers’ customization requirements. Guangdong Kenwei is located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province. The company is equipped with an automated weighing and packaging system and has comprehensive capabilities in design and development, manufacturing, marketing, installation and commissioning, technical training, and after-sales service. It has established a good brand image and a reputation for thoughtful and fast service in the packaging machinery industry.

Our vision is to become the world's leading weighing packing machine manufacturer. Visit our website: https://www.kenweigroup.com/

How Kenwei helps customers minimize downtime

Kenwei offers tailored maintenance support, including spare-part kits for multihead weighers, scheduled service visits, remote diagnostics, and training programs for operators and maintenance staff. Our machines’ modular designs simplify cleaning and part replacement, shortening changeover and repair times.

Kenwei main products and competitive strengths

Primary products: Check Weigher, multihead weigher packing machine, multihead weigher, linear weigher, metal detector, packing machine, counting machine, combination weigher, food packaging machine, food packing machinery.

Core competitive strengths: high-speed, high-precision designs; modular and hygienic construction for quick cleaning; integrated automation packages; strong after-sales support; customization capabilities for special products or layouts.

Practical checklist: 10 quick maintenance actions you can implement today (: multihead weigher checklist)

- Create a one-page daily checklist and post it at the machine.

- Assign responsibility for each task and add signatures.

- Order critical spares (loadcell, vibration motor, key sensors) to keep on-site.

- Start simple vibration trending for one motor to learn behavior over 90 days.

- Schedule quarterly calibration with a certified weight kit.

- Implement software backup policy: backup after any recipe change.

- Introduce a clean-before-changeover rule for mix-sensitive lines.

- Test reject pathways weekly and clear blockages immediately.

- Log every fault code and corrective action in a maintenance log.

- Set a yearly budget for preventive replacements rather than emergency purchases.

FAQ (Frequently Asked Questions)

Q: How often should I calibrate a multihead weigher?

A: Calibrate whenever you change product, after mechanical work that affects loadcells, and on a scheduled basis (monthly to quarterly) depending on line criticality. Highly regulated or high-value products often require more frequent calibration.

Q: What are the most common causes of weighing inaccuracy?

A: Common causes include loadcell damage or contamination, loose mechanical mounts, buildup of product on hoppers, electrical noise or poor grounding, and incorrect software compensation settings.

Q: Can I clean a multihead weigher with high-pressure water?

A: Avoid direct high-pressure washing on electronic housings and loadcells. Use appropriate cleaning methods per OEM instructions. Many machines have IP-rated components that tolerate washdown, but confirm before applying pressure washing.

Q: How can predictive maintenance help my weigher line?

A: Predictive maintenance identifies trends (vibration, temperature, cycle counts) to schedule service before failure. This reduces unscheduled downtime and helps optimize spare-part inventory.

Q: What spare parts should I always keep on-site?

A: Keep at least one spare loadcell, one vibration motor, spare belts, and key sensors (photoeyes). The exact list depends on your machine model and production criticality.

Q: When should I contact Kenwei for service?

A: Contact Kenwei for persistent calibration drift, repeated electrical faults, significant mechanical damage, or when you want a certified annual inspection and operator training. Kenwei provides installation, training, and after-sales service.

Contact us / View products (CTA)

For machine specifications, spare parts, or to schedule a maintenance audit, contact Kenwei sales and service: https://www.kenweigroup.com/. Our team can recommend a maintenance package tailored to your production needs and help implement predictive maintenance upgrades.

Sources

- EHEDG (European Hygienic Engineering & Design Group) guidance on hygienic equipment design and cleaning recommendations.

- U.S. Food and Drug Administration (FDA) Food Code: Equipment, Utensils, and Food-Contact Surfaces guidelines.

- PMMI / Industry whitepapers on predictive maintenance and packaging machinery uptime (industry association insights).

- OEM maintenance best practices and aggregate industry maintenance surveys (manufacturing maintenance literature).

What are the application scenarios of packing machines?

Top 10 food metal detector Manufacturers and Supplier Brands in America

Procurement Checklist for Multihead Weigher in Pickle Production

Multihead Weigher Technology Trends 2026

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About After Sales Support

How about the after-sales service?

Warranty :2 years

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

16 Head Three Layer Multihead Weigher for Granular and Irregular Materials

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei