Multihead Weigher Technology Trends 2026

- Multihead Weigher Technology Trends 2026

- Why multihead weigher technology matters — buy multihead weigher to improve throughput

- Trend 1: Full automation and Industry 4.0 integration — multihead weigher supplier capabilities

- Trend 2: AI and predictive maintenance for multihead weigher maintenance

- Trend 3: Servo-driven motion control — improve multihead weigher performance

- Trend 4: Flexibility and quick changeovers — multihead weigher packing machine requirements

- Trend 5: Hygiene and food-safety compliance — multihead weigher food packaging machine standards

- Trend 6: Energy efficiency and sustainable packaging — buy multihead weigher with low energy use

- Trend 7: Enhanced user interfaces and operator training — multihead weigher supplier support

- Comparing core multihead weigher technologies — multihead weigher technology comparison table

- How to select and buy a multihead weigher — multihead weigher procurement checklist

- Integration and commissioning — get multihead weigher installation and commissioning support

- Why choose Kenwei — Kenwei is a powerful manufacturer of multi-head weighers

- Implementation roadmap — from pilot to full production when you buy multihead weigher

- FAQ — common questions about multihead weigher selection and purchase

- Q: How do I decide the right number of heads for my multihead weigher?

- Q: What maintenance should I expect for a multihead weigher?

- Q: Can a multihead weigher handle fragile products like chips or biscuits?

- Q: How do multihead weighers support traceability and compliance?

- Q: What is the typical ROI period after I buy a multihead weigher?

- Contact and call-to-action — contact Kenwei / view products

- References

Multihead Weigher Technology Trends 2026

Why multihead weigher technology matters — buy multihead weigher to improve throughput

As manufacturers face rising labor costs, SKU proliferation, and tighter food-safety regulations, multihead weighers remain central to high-speed, accurate packaging lines. A modern multihead weigher reduces giveaway, increases throughput, and enables automated combinational weighing for mixed-product packs. For procurement teams deciding whether to buy a multihead weigher, the 2026 landscape emphasizes connectivity, flexibility, and lower total cost of ownership rather than simple capital cost.

Trend 1: Full automation and Industry 4.0 integration — multihead weigher supplier capabilities

By 2026, multihead weighers are increasingly expected to be more than stand-alone machines. Integration with MES, ERP, and cloud platforms is common. Suppliers now provide standardized industry protocols (OPC UA, MQTT) and APIs so weighers can report production counts, reject rates, and traceability data in real time. Purchasing from a multihead weigher supplier that supports Industry 4.0 reduces manual data entry, shortens response times to issues, and enables centralized production monitoring across plants.

Trend 2: AI and predictive maintenance for multihead weigher maintenance

AI and machine learning models are being embedded in control systems to detect early signs of wear or imbalance. Predictive maintenance minimizes downtime by forecasting when components like vibratory feeders, hopper sensors, or motors need service. For operations, this means fewer unplanned stops and more predictable maintenance budgets. When discussing service contracts with suppliers, ask for on-board analytics, remote diagnostics, and model-driven alerts that reduce mean time to repair.

Trend 3: Servo-driven motion control — improve multihead weigher performance

Servo-driven feeders and electronically controlled gates have become standard in higher-end multihead weighers. Compared with older pneumatic or cam-based designs, servo systems deliver faster response, higher accuracy, and easier recipe tuning. The result is higher picks per minute, better distribution control for fragile products, and smoother changeovers between SKUs. Buyers should evaluate weighers with closed-loop motion control and position feedback for repeatable precision.

Trend 4: Flexibility and quick changeovers — multihead weigher packing machine requirements

Retailers demand more SKUs and seasonal packs; therefore, flexibility is a top procurement criterion. New multihead weigher packing machine designs emphasize tool-less adjustments, modular feeders, and stored recipes to reduce changeover times to minutes rather than hours. Machines that support a wide range of portion sizes and mixed-material packaging give manufacturers commercial advantages by enabling smaller production runs without sacrificing efficiency.

Trend 5: Hygiene and food-safety compliance — multihead weigher food packaging machine standards

Food safety remains a non-negotiable requirement. Hygienic design — open frames, sloped surfaces, stainless-steel AISI 304/316 contact parts, and IP-rated motors — simplifies cleaning and reduces microbial harborage points. Suppliers increasingly offer washdown-capable components and validation documentation to support HACCP, BRC, and FSMA compliance. When evaluating equipment, insist on sanitary designs and accessible components for fast cleaning cycles.

Trend 6: Energy efficiency and sustainable packaging — buy multihead weigher with low energy use

Sustainability goals drive investment decisions. Energy-efficient drives, optimized vacuum systems, and intelligent standby modes can reduce energy consumption during low-demand periods. Additionally, multihead weighers that enable accurate portioning reduce food waste and packaging overfill, contributing to sustainability targets. Many companies now include energy performance as part of total cost of ownership calculations.

Trend 7: Enhanced user interfaces and operator training — multihead weigher supplier support

Simplified HMI with recipe icons, touchscreens, and guided troubleshooting lowers operator error rates. Remote access and augmented-reality-assisted support accelerate troubleshooting and training. For buyers, supplier-provided training and digital manuals are as important as the machine itself; they reduce ramp-up time and help maintain line efficiency.

Comparing core multihead weigher technologies — multihead weigher technology comparison table

The table below compares common multihead weigher architectures and highlights trade-offs relevant to procurement.

| Technology | Speed & Throughput | Accuracy & Giveaway | Flexibility (SKUs, changeovers) | Maintenance & Reliability | Typical Use Case |

|---|---|---|---|---|---|

| Traditional cam-driven / pneumatic | Moderate | Good | Lower (mechanical adjustments) | Higher maintenance due to mechanical parts | Simple, high-volume single-SKU lines |

| Servo-driven multihead | High | Very high (better portion control) | High (programmed recipes) | Lower mechanical wear; requires electrical expertise | Mixed SKUs, fragile items, high-speed lines |

| AI-assisted / Cloud-enabled systems | Variable (depends on integration) | Optimized over time via learning | Very high (adaptive recipes) | Predictive maintenance lowers downtime | Smart factories requiring traceability and analytics |

Source: Kenwei product literature and industry whitepapers on automated weighing systems.

How to select and buy a multihead weigher — multihead weigher procurement checklist

When evaluating offers from multihead weigher suppliers, use this checklist to compare candidates: throughput (kg/hr or packs/min), accuracy (target giveaway), number of heads, servo vs pneumatic drive, sanitary design, connectivity (OPC UA, Ethernet/IP), spare-parts availability, lead time, installation and commissioning support, training, warranty and service level agreements. Request on-site or virtual trials with your products to verify performance under real conditions before purchase.

Integration and commissioning — get multihead weigher installation and commissioning support

Successful implementation depends on precise mechanical alignment, correct electrical integration, and recipe validation. Ask suppliers about field commission teams, test reports, validation documentation, and training plans. A well-run commissioning phase should include baseline SOPs, operator training, and spare parts recommendations that minimize time-to-production.

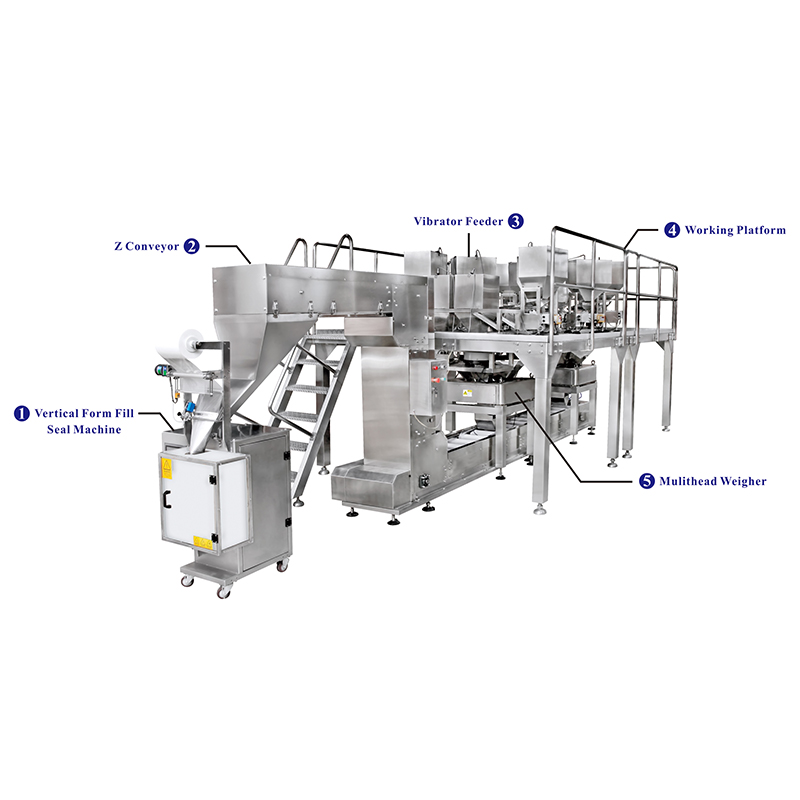

Why choose Kenwei — Kenwei is a powerful manufacturer of multi-head weighers

Kenwei is a powerful manufacturer of multi-head weighers. We are committed to the development and manufacturing of metal detectors, multi-head weighers, linear weighers, and check weighers. Our machines are characterized by high speed and high precision. We also provide our customers with one-stop automated weighing and packaging solutions to meet our customers’ customization requirements.

Guangdong Kenwei is located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province. The company is equipped with an automated weighing and packaging system and has comprehensive capabilities in design and development, manufacturing, marketing, installation and commissioning, technical training, and after-sales service. It has established a good brand image and a reputation for thoughtful and fast service in the packaging machinery industry.

Our vision is to become the world's leading weighing packing machine manufacturer. For buyers looking to purchase multihead weighers, Kenwei offers:

- High-speed multihead weighers with servo motion control for precision and throughput.

- Hygienic designs and food-grade materials to meet compliance requirements.

- One-stop solutions including metal detectors, check weighers, linear weighers, counting machines, combination weighers, and packing machines.

- Comprehensive services: design, customization, installation & commissioning, training, and after-sales support.

Main products and core competitive strengths: Check Weigher, multihead weigher packing machine, multihead weigher, linear weigher, metal detector, packing machine, counting machine, combination weigher, food packaging machine, food packing machinery. Kenwei’s core strengths are high speed and high precision, modular system design for fast changeovers, integrated automation expertise, and rapid global support networks.

Visit Kenwei to view product specifications and request demonstrations: https://www.kenweigroup.com/

Implementation roadmap — from pilot to full production when you buy multihead weigher

A typical rollout roadmap for adding or replacing multihead weighers includes: product trials and acceptance tests; line simulation and layout planning; mechanical and electrical installation; commissioning and recipe validation; operator training and documentation; ramp-up with performance monitoring; continuous improvement sessions to tune speed and reduce giveaway. Working closely with your supplier during each step reduces risk and shortens time-to-value.

FAQ — common questions about multihead weigher selection and purchase

Q: How do I decide the right number of heads for my multihead weigher?

A: Choose based on target throughput, portion size range, and product characteristics. More heads generally allow higher speeds and better distribution control for small portions; however, they increase capital cost. Conduct on-site product trials with suppliers to determine optimal configuration.

Q: What maintenance should I expect for a multihead weigher?

A: Regular checks include feeder tuning, load-cell calibration, cleaning of contact surfaces, inspection of gates and seals, and software backups. Predictive maintenance options can further reduce unplanned downtime. Negotiate a service contract for critical spare parts and response times.

Q: Can a multihead weigher handle fragile products like chips or biscuits?

A: Yes. Look for gentle vibratory feeders, adjustable drop heights, and gentle forming funnels. Servo control and specialized liners reduce breakage and maintain presentation for fragile items.

Q: How do multihead weighers support traceability and compliance?

A: Modern weighers log production data, batch IDs, and reject records. With MES or cloud integration, that data can be associated with lot numbers and retained for audits. Ask suppliers about their data retention formats and export options.

Q: What is the typical ROI period after I buy a multihead weigher?

A: ROI depends on labor savings, reduced giveaway, and throughput improvements. For many lines, payback can occur within 12–36 months but should be calculated specifically for your production volumes and labor costs.

Contact and call-to-action — contact Kenwei / view products

Ready to evaluate multihead weighers for your line? Contact Kenwei for product demos, technical specifications, and custom solutions. Visit our website to view product lines and request a quote: https://www.kenweigroup.com/

References

- Kenwei product literature and technical specifications (Kenwei Group website).

- Packaging machinery and automation industry whitepapers and state-of-industry reports (PMMI and similar industry bodies).

- Market research summaries on packaging automation trends (Grand View Research, MarketsandMarkets).

Everything You Need to Know About food metal detector

Top benefits of a 14 head multihead weigher for pickle packaging

How to Validate and Test Food Metal Detectors Effectively

Integrating a Multihead Weigher into Pickles Packaging Lines

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

16 Head Three Layer Multihead Weigher for Granular and Irregular Materials

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei