Multihead vs Linear Weigher Comparison 2026

- Multihead vs Linear Weigher Comparison 2026

- What is a multihead weigher and why it matters for high-volume packing?

- What is a linear weigher and where it still wins?

- Key performance metrics: speed, accuracy and throughput for multihead weigher buyers

- Product suitability and application scenarios for multihead weighers

- Multihead weigher: handling mixed and delicate products

- Linear weigher: when simplicity and low cost are priorities

- Cost of ownership and ROI: comparing multihead weigher price and lifecycle expenses

- — buy multihead weigher: what to evaluate

- Hygiene, maintenance and operational reliability — what the 2026 buyer should know

- Maintenance complexity and spare parts

- Integration and automation: ensuring the multihead weigher fits your line

- Automation and data: Industry 4.0 readiness

- Side-by-side comparison table: multihead weigher vs linear weigher (typical ranges)

- How to choose the right machine in 2026 — practical checklist

- Why choose Kenwei for your multihead weigher and full packaging solution?

- Kenwei product range and core strengths

- Practical buying tips and negotiation points when acquiring a multihead weigher

- FAQ — Frequently Asked Questions (related to multihead weigher and linear weigher)

- Contact and next steps — view products or talk to a specialist

- References and data sources

Multihead vs Linear Weigher Comparison 2026

What is a multihead weigher and why it matters for high-volume packing?

A multihead weigher is an automated combination-weighing machine that uses multiple weigh heads to combine precise portion weights rapidly and consistently. Designed for high-speed snack, confectionery, frozen food, and fresh produce lines, the multihead weigher calculates optimal head combinations to reach a target weight for each package. If you're comparing options to scale production or improve yield, understanding the multihead weigher's strengths — speed, repeatable accuracy, and flexible combination logic — is essential. The multihead weigher remains the go-to technology where high throughput and low giveaway are business priorities.

What is a linear weigher and where it still wins?

A linear weigher (sometimes called a single-head linear feeder) uses one or more linear hoppers or feeders to deliver a continuous flow of product to a single weighing cell. Linear weighers are often simpler mechanically, easier to maintain, and lower in upfront cost than multihead machines. They are well-suited to products that flow well and where budget or footprint constraints are important. For applications requiring simpler portioning and moderate speeds, linear weighers can offer reliable performance with lower complexity.

Key performance metrics: speed, accuracy and throughput for multihead weigher buyers

When evaluating multihead weigher vs linear weigher, three metrics typically determine the right choice: processing speed (packs per minute), dosing accuracy (average deviation and giveaway), and net throughput (considering changeovers and rejects). The multihead weigher achieves higher peak speeds on many product types because it uses parallel weighing heads and combination algorithms. However, real-world throughput also depends on product characteristics, packaging machinery downstream, and operator skill.

Product suitability and application scenarios for multihead weighers

Choosing between multihead and linear weighers depends heavily on the product being packed. Multihead weighers typically excel with free-flowing, particulate, and discrete products such as chips, nuts, frozen vegetables, candy, and granulated ingredients. They handle variable piece size and deliver tighter weight control, which reduces giveaway. Linear weighers are often preferred for fragile items, large single-piece products, sticky products, or very small batches where the simpler feed method reduces damage and improves handling. Understanding your product characteristics is the first step in selecting the right machine.

Multihead weigher: handling mixed and delicate products

Multihead systems can be fitted with different chute geometries, vibration settings, and gentle feed options, making them versatile for fragile or mixed-size products. When product integrity matters (e.g., whole nuts, bakery pieces), a multihead weigher with gentle feeding packages more consistently than high-speed vibratory linear feeders that can cause breakage.

Linear weigher: when simplicity and low cost are priorities

Linear weighers can be ideal when capital expenditure needs to be minimized, or when product flow characteristics make multihead combination logic unnecessary. For simple granular products or where production runs are short and changeovers frequent, a linear weigher delivers a straightforward, low-maintenance solution.

Cost of ownership and ROI: comparing multihead weigher price and lifecycle expenses

Upfront machine price is only part of the story. Total cost of ownership (TCO) should include acquisition cost, installation and integration, spare parts and consumables, maintenance labor, product giveaway, and expected lifetime. Multihead weighers typically have higher initial costs but can produce significant savings in reduced giveaway and higher throughput, delivering faster ROI in high-volume operations. Linear weighers often have lower purchase prices and simpler maintenance, making them suitable for lower-volume or budget-sensitive operations.

— buy multihead weigher: what to evaluate

When evaluating to buy a multihead weigher, ask for documented case studies showing yield improvement and real throughput, request total cost of ownership projections, and confirm spare parts availability and local service. Multihead weigher price varies widely by head count, materials (stainless steel, washdown rating), and control sophistication — always get quotes matched to your product and target pack rates.

Hygiene, maintenance and operational reliability — what the 2026 buyer should know

Hygiene and downtime have direct financial impact. Multihead weighers designed for easy cleaning (IP65/IP66 where needed, quick-release chutes, tool-free removal of product-contact parts) reduce washdown time and risk of contamination. Linear weighers can be simpler to disassemble but may require more manual handling with some product types. Evaluate machine design for CIP (clean-in-place) compatibility if you run wet or sticky products frequently.

Maintenance complexity and spare parts

Multihead weighers have more mechanical and electronic components, which can mean higher spare parts inventory and specialized maintenance. However, reputable manufacturers provide modular designs, remote diagnostics, and training to reduce downtime. Linear weighers' simplicity often means easier in-house maintenance but watch for accuracy drift issues that require recalibration.

Integration and automation: ensuring the multihead weigher fits your line

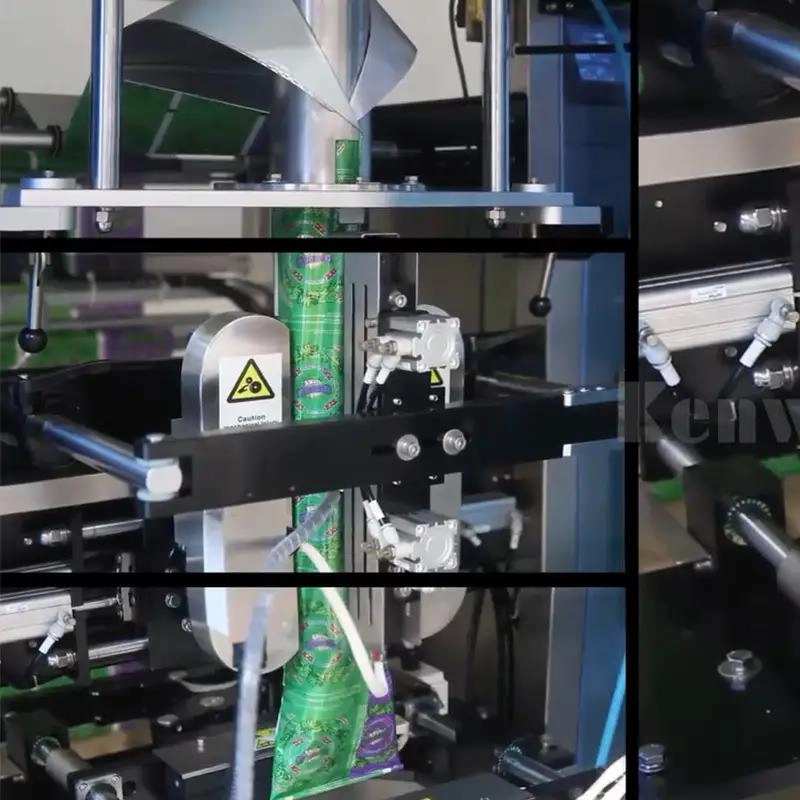

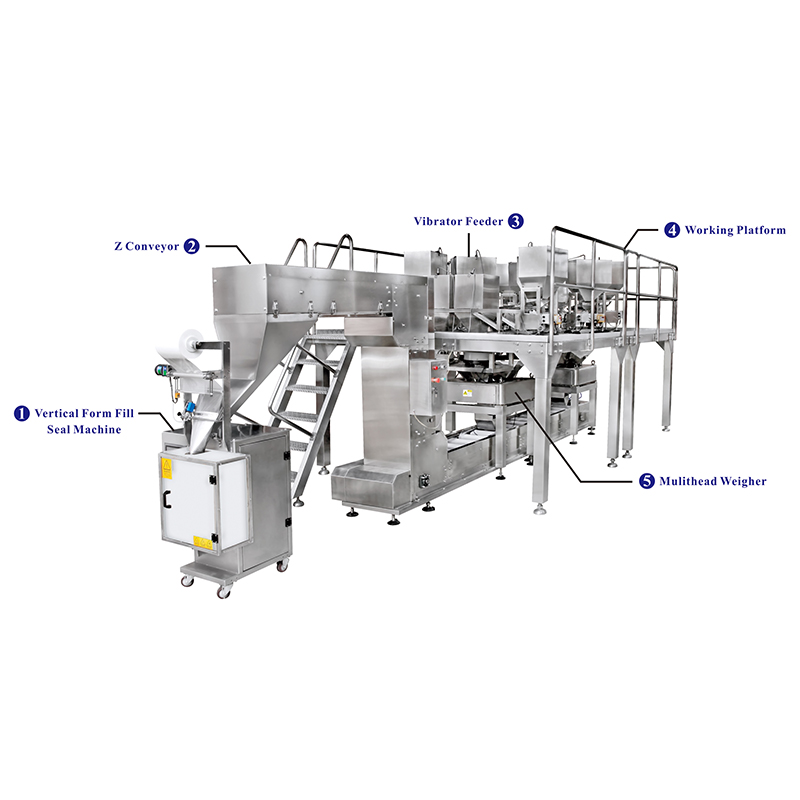

In modern packaging lines the weigher must integrate with fillers, bagmakers, metal detectors, check weighers, and robots. Multihead weighers are often chosen because they synchronize well with high-speed vertical form-fill-seal (VFFS) machines and multi-track packaging lines. Ensure that the machine's PLC and communication protocols (Ethernet/IP, Profinet, Modbus) are compatible with your line controllers, and confirm integration support from the supplier.

Automation and data: Industry 4.0 readiness

Look for weighers offering digital reporting for weight trends, uptime, and mass-balance data. This helps operations teams manage yield and provide traceability for food safety audits. Multihead weighers increasingly provide cloud-ready diagnostics and recipe management to speed changeovers and track KPIs.

Side-by-side comparison table: multihead weigher vs linear weigher (typical ranges)

Below is a practical comparison reflecting industry-typical performance ranges. Actual results vary by machine model, head count, product and packaging configuration.

| Feature | Multihead Weigher | Linear Weigher |

|---|---|---|

| Typical Speed (packs/min) | 30–240 (depending on head count and product) | 20–120 (product-dependent) |

| Typical Dosing Accuracy | ±0.1–±2.0 g (product dependent; excellent for small particulates) | ±0.5–±5.0 g (varies; less precise for small, variable pieces) |

| Capital Cost (approx.) | $30,000–$250,000+ (depending on configuration) | $5,000–$60,000 (simpler designs are less expensive) |

| Best for | Snack foods, confectionery, frozen veggies, granules, mixed lines | Granules, simple particulate products, fragile large pieces, low-volume lines |

| Footprint & Complexity | Larger footprint, more complex mechanical/electrical systems | Smaller footprint, simpler mechanics |

| Changeover Flexibility | High — recipe-based setups and quick-change parts | Moderate — may require manual adjustments for different products |

| Sanitation & CIP | Many models designed for easy washdown and tool-free dismantling | Often simple to clean but depends on feeder design |

Sources for ranges: industry equipment reviews and supplier specifications (see references below).

How to choose the right machine in 2026 — practical checklist

To select the best technology, follow this practical checklist:

- Define target throughput (packs/min) and pack formats.

- Test-run your product(s) on candidate machines — request on-site or trial lab trials.

- Compare total cost of ownership, not just purchase price: include giveaway, downtime, and maintenance.

- Confirm hygiene ratings and cleanability for food safety compliance.

- Ensure controls and communication protocols match your line automation needs.

- Validate supplier support: spare parts, training, local service response time.

Why choose Kenwei for your multihead weigher and full packaging solution?

Kenwei is a powerful manufacturer of multi-head weighers. We are committed to the development and manufacturing of metal detectors, multi-head weighers, linear weighers, and check weighers. Our machines are characterized by high speed and high precision. We also provide our customers with one-stop automated weighing and packaging solutions to meet our customers’ customization requirements. Guangdong Kenwei is located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province. The company is equipped with an automated weighing and packaging system and has comprehensive capabilities in design and development, manufacturing, marketing, installation and commissioning, technical training, and after-sales service. It has established a good brand image and a reputation for thoughtful and fast service in the packaging machinery industry. Our vision is to become the world's leading weighing packing machine manufacturer.

Kenwei product range and core strengths

Kenwei's main products include Check Weigher, multihead weigher packing machine, multihead weigher, linear weigher, metal detector, packing machine, counting machine, combination weigher, food packaging machine, and food packing machinery. Core competitive advantages include high-speed and high-precision equipment, flexible customization, integrated line solutions, and strong after-sales support. Kenwei emphasizes modular designs for fast changeovers, sanitary construction for food safety, and digital-ready controls to support modern manufacturing demands. To see our solutions and request a quote, visit https://www.kenweigroup.com/.

Practical buying tips and negotiation points when acquiring a multihead weigher

When negotiating with suppliers, request the following: a detailed quoted scope (including installation, training, and spare parts), documented performance guarantees (target packs/min and accuracy on your product), onsite acceptance testing, and a clear warranty and service SLA. Also clarify software/license terms for recipe management and ensure that upgrades and remote diagnostics are included or priced transparently.

FAQ — Frequently Asked Questions (related to multihead weigher and linear weigher)

Q: Which is better for snacks — multihead or linear weigher?

A: For snacks, multihead weighers are typically better due to higher speed and tighter weight control, reducing giveaway. Linear units may be used for lower-speed or budget lines.

Q: How much does a mid-range multihead weigher cost?

A: Mid-range multihead weighers commonly start in the tens of thousands of USD and can rise substantially depending on head count, sanitary design, and automation features. Always request a full quote for your required configuration.

Q: Can weighers handle sticky or frozen products?

A: Yes — both multihead and linear weighers can be adapted with coatings, heated chutes, or specialized feeders. Multihead systems often offer better combination strategies for variable product pieces.

Q: How do you test a machine before buying?

A: Ask for a trial with your actual product, either at the supplier’s demo lab or onsite. Verify speed, accuracy, changeover time, and cleanability. Obtain a written acceptance test.

Q: What are common causes of weighing errors?

A: Inconsistent feed rates, product bridging, vibration or unstable mounting, and poor calibration can cause errors. Proper feeder tuning and routine maintenance minimize issues.

Contact and next steps — view products or talk to a specialist

If you’re ready to evaluate multihead weighers for your line or want help deciding between multihead and linear solutions, Kenwei can help. Visit https://www.kenweigroup.com/ to view product families, request quotes, or schedule an on-site demo. Our team provides consultation, customized solutions, and after-sales support to ensure optimal line performance and ROI.

References and data sources

- Packaging World — industry equipment reviews and supplier specifications.

- PMMI (The Association for Packaging and Processing Technologies) — technology overviews on weighing and combination weighers.

- Pack Expo / trade show materials — supplier spec sheets and demo performance figures.

- Food Engineering — articles on weighing accuracy, hygiene design and automated packaging lines.

- Manufacturer product datasheets (typical industry ranges aggregated for comparison).

For tailored advice, trials, or pricing on multihead weighers and integrated packaging solutions, contact Kenwei via https://www.kenweigroup.com/.

Where to Buy checkweighers

What are the application scenarios of automatic check weigher?

AI and Vision Systems for Multihead Weighers 2026

How to Choose a Vertical Packaging Machine for High Throughput

About Price and payment

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

16 Head Three Layer Multihead Weigher for Granular and Irregular Materials

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei