Integrating Linear Weighers with Automated Lines: Practical Guide for Packaging Efficiency

- Integrating Linear Weighers with Automated Lines: Practical Guide

- Overview — Why Integrating Linear Weighers with Automated Lines Matters

- Key Business Intent — What Users Searching Integrating Linear Weighers with Automated Lines Want

- Understanding Linear Weighers — Core Capabilities and Typical Applications

- Integration Basics — Mechanical and Layout Considerations

- Control Systems — PLCs, I/O, and Communication Protocols

- Synchronization — Timing, Speed and Product Transfer

- Quality and Accuracy — Calibration, Weight Control, and Rejection Logic

- Data and Traceability — MES/ERP Integration and Industry 4.0

- Hygiene and Compliance — Food Safety and Cleanability

- Validation and Testing — FAT, SAT, and On-site Commissioning

- ROI and Cost Considerations — Calculating Payback

- Common Integration Pitfalls and How to Avoid Them

- Case Comparison — Linear Weighers vs Multihead Weighers (Integration Metrics)

- Best Practices Checklist for Smooth Integration

- Conclusion — Practical Steps to a Successful Integration

- Final Recommendations

- Frequently Asked Questions

- References

Integrating Linear Weighers with Automated Lines: Practical Guide

Overview — Why Integrating Linear Weighers with Automated Lines Matters

Integrating linear weighers with automated lines is a crucial step for manufacturers aiming to improve throughput, reduce giveaway, and ensure product quality. Linear weighers (single-head or multi-stream linear systems) are often chosen for fragile, sticky, or aerated products and for packaging formats where precise continuous dosing is required. When properly integrated, they provide consistent fill accuracy and simplify downstream operations such as sealing, labeling, and case packing.

Key Business Intent — What Users Searching Integrating Linear Weighers with Automated Lines Want

is predominantly commercial and operational: users want practical integration steps, communication protocols, layout guidelines, performance trade-offs, and ROI expectations. They are typically engineers, production managers, or procurement specialists assessing whether linear weighers fit their automated line and how to minimize downtime, meet food safety standards, and achieve high-speed accuracy.

Understanding Linear Weighers — Core Capabilities and Typical Applications

Linear weighers deliver product by a linear dosing mechanism rather than a multi-head combination. Typical applications include powders, flakes, granules, viscous pastes, and fragile items. Strengths include gentle handling and consistent portioning in single or multiple lanes. Average dosing rates vary widely by product: small dry items can be dosed hundreds of times per minute per lane, while viscous products may be much slower. Choose a linear weigher when product integrity or feed characteristics make multihead solutions less reliable.

Integration Basics — Mechanical and Layout Considerations

Successful mechanical integration begins with footprint planning, infeed design, and conveying synchronization. Ensure the linear weigher's discharge aligns precisely with the packaging machine inlet (vertical drop, chute, or feed belt). Allow service access and maintenance clearance as specified by the manufacturer. Consider infeed hoppers, vibratory feeders, or metering screws upstream to maintain consistent product flow into the linear weigh head(s).

Control Systems — PLCs, I/O, and Communication Protocols

Integration requires robust control logic and clear communication channels. Most modern lines use industrial Ethernet protocols: Ethernet/IP, Profinet, Modbus TCP, or EtherCAT. The linear weigher should exchange start/stop commands, target weight setpoints, machine states, and fault codes with the line PLC. Kenwei machines support common industrial protocols and can be configured to send real-time weight and production data for line orchestration and traceability.

Synchronization — Timing, Speed and Product Transfer

Precise synchronization avoids product spill or line stoppages. Match conveyor speeds, indexing timing, and drop timing so the weigher discharges only when the downstream package or hopper is in position. Use sensors (photoeyes, encoders, and proximity switches) and closed-loop feedback from the PLC to adjust timing dynamically. For high-speed lines, consider servo-driven gates or timed chutes to reduce mechanical lag and improve repeatability.

Quality and Accuracy — Calibration, Weight Control, and Rejection Logic

Calibration routines and statistical weight control (SQC) are essential. Implement periodic check-weighing and automatic calibrations during low-production windows. Integrate inline checkweighers or metal detectors downstream as part of the reject logic. Typical target accuracy depends on product and pack weight — many lines aim for ±0.5% to ±2% of nominal pack weight. Use trending data to adjust dosing parameters and minimize giveaway while maintaining compliance.

Data and Traceability — MES/ERP Integration and Industry 4.0

Data from linear weighers is valuable for quality control and traceability. Configure the system to log batch IDs, weights, cycle counts, and alarms and to transmit them to MES or ERP systems. Use standard data models (OPC-UA, MQTT) for Industry 4.0 compatibility. Real-time dashboards help production managers respond quickly to drift or product changeovers.

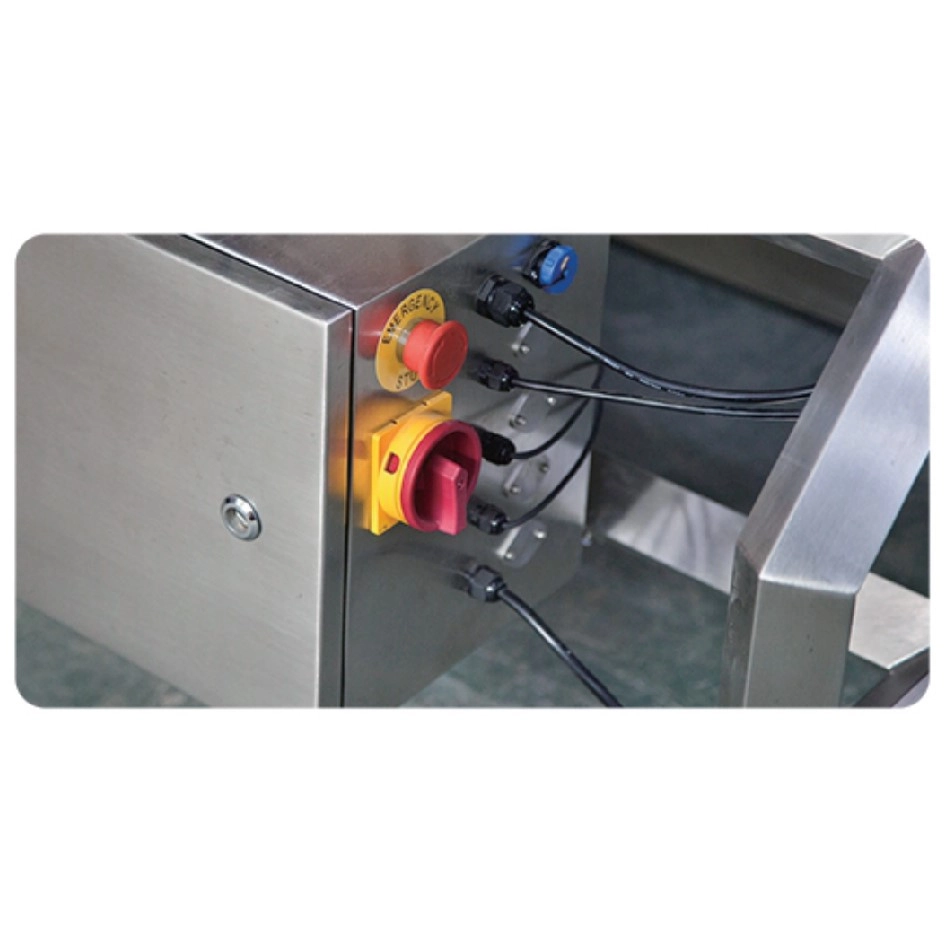

Hygiene and Compliance — Food Safety and Cleanability

Linear weighers integrated into food or pharmaceutical lines must meet hygiene standards. Choose IP-rated electrical enclosures, stainless-steel contact surfaces, and designs that minimize crevices. Ensure the machine supports CIP (clean-in-place) or easy washdown procedures and that product contact materials comply with relevant food-contact regulations (e.g., FDA, EU 10/2011 materials guidance).

Validation and Testing — FAT, SAT, and On-site Commissioning

Follow a structured validation process: Factory Acceptance Test (FAT) to verify performance per spec, Site Acceptance Test (SAT) after installation, and commissioning which includes line-level tests, recipe validation, and failure mode exercises. Run full-run trials with representative product and packaging to verify integration points and cycle robustness before full production release.

ROI and Cost Considerations — Calculating Payback

ROI depends on labor savings, reduced giveaway, improved throughput, and decreased rework. A simple ROI approach: estimate incremental throughput (packs/hour), net margin per pack, and the capital cost. For example, increasing throughput by 20% on a line producing 3,000 packs/day at $0.10 margin per pack yields an additional $60/day. Over a year (250 production days) that’s $15,000, which shortens payback on modest investments. Always run plant-specific scenarios to capture downtime risks and maintenance costs.

Common Integration Pitfalls and How to Avoid Them

Typical pitfalls include mismatched control protocols, inadequate infeed, insufficient maintenance access, and underestimating product variability. Mitigate risks by involving mechanical, electrical, and process engineers early, performing on-site product trials, and selecting a supplier that offers line-level integration support and responsive after-sales service — strengths that Kenwei emphasizes in its one-stop automated weighing and packaging approach.

Case Comparison — Linear Weighers vs Multihead Weighers (Integration Metrics)

The following table outlines typical integration metrics to help choose the right technology for your automated line.

| Metric | Linear Weigher | Multihead Weigher |

|---|---|---|

| Typical Best Use | Fragile, sticky, viscous, single-lane precise dosing | High-speed discrete items (snacks, nuts), multi-lane batching |

| Integration Complexity | Medium — focus on infeed and timing | Medium-High — multiple hoppers and discharge coordination |

| Typical Throughput | Variable by product; often lower per head but scalable by lanes | High — industry systems often 30–150 packs/min depending on model |

| Accuracy | High for continuous dosing; good for small weights | Very high for combination weighing due to multiple heads |

| Cleaning / Maintenance | Easier for single-stream linear designs | More complex due to many moving parts |

Best Practices Checklist for Smooth Integration

Follow this checklist when planning to integrate linear weighers with automated lines: 1) Define product characteristics and target speed, 2) Run lab and on-site product trials, 3) Agree communication protocols and data points, 4) Plan mechanical alignment and maintenance access, 5) Implement checkweighing and rejection logic, 6) Validate hygiene and regulatory compliance, 7) Schedule FAT/SAT and operator training.

Conclusion — Practical Steps to a Successful Integration

Final Recommendations

Integrating linear weighers with automated lines delivers reliable performance for many product types when mechanical, electrical, and data integration are handled collectively. Prioritize early cross-functional planning, choose equipment that supports standard industrial protocols, and partner with a vendor experienced in line-level deployments. Kenwei’s one-stop solutions, combining weighers, metal detectors, and checkweighers, simplify integration and reduce project risk for manufacturers seeking accurate, high-speed automated packaging.

Frequently Asked Questions

How do I decide between a linear weigher and a multihead weigher?Consider your product characteristics (fragility, stickiness), target throughput, and packaging format. Use linear weighers for gentle, continuous dosing; choose multihead for very high-speed discrete counting and combination weighing.

What communication protocols should be standard when integrating weighers?Use industrial Ethernet protocols widely supported in modern lines: Ethernet/IP, Profinet, Modbus TCP, or OPC-UA for Industry 4.0. Ensure the weigher and PLC support the chosen protocol.

How much footprint and maintenance clearance is typically needed?Allow at least 0.5–1.0 meter clearance on service sides for smaller linear weighers; larger systems require more. Confirm with supplier dimension drawings and include access for daily cleaning and component replacement.

How do I validate weighing accuracy after integration?Perform FAT and SAT tests with representative product and packaging. Implement routine calibrations, inline checkweigher cross-checks, and statistical weight control to maintain accuracy.

What is the expected payback period for integrating a linear weigher?Payback depends on throughput gain, reduction in giveaway, labor savings, and capital cost. For many lines, payback ranges from 12 to 36 months — run a plant-specific ROI with conservative assumptions.

References

- Kenwei official website and product literature (Kenwei Group)

- PMMI — The Association for Packaging and Processing Technologies (industry white papers on weighing and filling)

- Packaging Europe — articles on weighing technology and automation trends

- Food Processing magazine — equipment integration and line optimization articles

- Industry equipment datasheets and machine manuals (typical vendor specifications for linear and multihead weighers)

Integrating Multihead Weighers with Food Packing Machines

How G5020 Reject Systems Reduce Product Recalls

Top 10 metal detector machine Manufacturers and Supplier Brands in America

Selecting Good Metal Detectors for High-Speed Production Lines

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About After Sales Support

How about the after-sales service?

Warranty :2 years

About products customization

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei