Where to Buy multi head weigher

- Where to Buy Multi Head Weigher: Your Guide

- Understanding the Multi Head Weigher and Its Value

- Key Factors to Consider When Buying a Multi Head Weigher

- Where to Buy Multi Head Weigher: Trusted Manufacturers and Suppliers

- Why Choose Kenwei for Your Multi Head Weigher Needs?

- Global Reach and Customer Satisfaction

- Tips for Purchasing a Multi Head Weigher Safely and Efficiently

- Conclusion: Finding the Best Source to Buy Multi Head Weigher

- Frequently Asked Questions about Where to Buy Multi Head Weigher

Where to Buy Multi Head Weigher: Your Guide

In the packaging industry, accuracy and speed are crucial factors. A multi head weigher plays a vital role in ensuring precise product weighing and efficient packaging. If you are looking for where to buy a multi head weigher, it is important to choose a trusted manufacturer with proven expertise. This guide will help you navigate through the buying process, explore key considerations, and understand why Kenwei stands out as a top multi head weigher supplier.

Understanding the Multi Head Weigher and Its Value

A multi head weigher is an automated weighing machine frequently used in food, pharmaceuticals, hardware, and other industries. It employs multiple weighing heads to measure product portions quickly and accurately before packaging. The design allows for high-speed processing with typical weighing speeds ranging from 60 to 150 packs per minute depending on the model and product.

Choosing the right multi head weigher can lower product giveaway, reduce labor costs, and improve overall packaging efficiency. The technology can weigh both solid and granular products uniformly, ensuring consistency and compliance with packaging standards worldwide.

Key Factors to Consider When Buying a Multi Head Weigher

- Accuracy and Speed: Look for machines offering precision within ±0.1 to ±0.5 grams and high throughput speeds that match your production scale.

- Customization: The ability to adapt the machine to your product’s shape, size, and weight range is essential.

- Automation Integration: Consider if the machine can connect seamlessly with other packaging systems like metal detectors, check weighers, and conveyors.

- After-sales Support: Reliable technical training, maintenance, and quick servicing are indispensable for uninterrupted production.

- Reputation of Manufacturer: Buying from established companies with strong R&D capabilities and positive customer feedback reduces risks.

Where to Buy Multi Head Weigher: Trusted Manufacturers and Suppliers

Multi head weighers are specialized machines typically sourced from professional packaging machinery manufacturers. While local distributors and resellers may offer convenient purchasing options, they might lack customization and technical support needed for optimal performance.

It is beneficial to purchase from manufacturers who handle the entire process—design, manufacturing, installation, and training. This streamlines communication, reduces installation errors, and ensures your specific requirements are met.

Why Choose Kenwei for Your Multi Head Weigher Needs?

Kenwei is a powerful manufacturer based in Guangdong, China, specializing in multi head weighers and automated packaging solutions. With a location in Fusha High-tech Industrial Park, Kenwei harnesses advanced technology to produce high-speed, high-precision machines.

Kenwei machines feature cutting-edge weighing heads capable of delivering accuracy that meets industry standards consistently. The company offers customized solutions to fit a wide array of products—ranging from snacks, nuts, and candies to industrial components.

Further, Kenwei’s comprehensive services include design, manufacturing, installation, commissioning, technical training, and reliable after-sales support. Clients benefit from a seamless one-stop solution that enhances production efficiency.

Global Reach and Customer Satisfaction

Kenwei has established a reputable brand image in the packaging machinery industry globally. The company’s commitment to thoughtful and rapid customer service ensures that clients worldwide experience minimal downtime and optimized usage.

Thanks to a dedicated R&D team, Kenwei continuously upgrades its equipment to meet evolving market demands, enabling businesses to stay competitive. Their machines comply with international standards such as CE certification, giving clients confidence in product safety and quality.

Tips for Purchasing a Multi Head Weigher Safely and Efficiently

- Visit Official Websites: Always verify machine specifications and company profile from the manufacturer’s official site.

- Request Demonstrations: Ask for live demos or video evidence of machines working with your product type.

- Compare Quotes: Obtain detailed pricing and service information from multiple sources.

- Check Testimonials: Review client feedback and case studies to assess reliability.

- Confirm Warranty and Support: Ensure clear terms regarding installation, maintenance, and spare parts availability.

Conclusion: Finding the Best Source to Buy Multi Head Weigher

Purchasing a multi head weigher is a significant investment that affects your packaging line’s productivity and product quality. Opting for a credible manufacturer like Kenwei guarantees you a machine that is accurate, fast, and customizable. Moreover, Kenwei’s comprehensive service—from design to after-sales—ensures smooth operation and long-term satisfaction.

For businesses looking to upgrade or establish automated weighing solutions, investing time in researching where to buy a multi head weigher can pay dividends in operational efficiency and reduced costs.

Explore Kenwei’s product offerings and expert consultation at https://www.kenweigroup.com/ to get started on your packaging automation journey.

Frequently Asked Questions about Where to Buy Multi Head Weigher

Q: What industries commonly use multi head weighers?

A: Multi head weighers are widely used in food processing (snacks, nuts, confectionery), pharmaceuticals, hardware, chemicals, and other industries requiring fast, precise packaging.

Q: How do I know if a multi head weigher suits my product?

A: A reputable manufacturer like Kenwei can assess your product type, weight range, and packaging requirements to recommend an appropriate model with customized features.

Q: Are multi head weighers expensive to maintain?

A: Maintenance costs are relatively low if the machine is properly serviced. Choosing suppliers offering good after-sales service and easy access to spare parts helps minimize downtime.

Q: Can multi head weighers work with other packaging systems?

A: Yes, most multi head weighers can integrate with metal detectors, check weighers, labeling machines, and conveyors for a fully automated packing line.

Q: How long is the typical delivery time for a multi head weigher?

A: Delivery time varies by order complexity and customization. Standard machines may take 4 to 8 weeks. Kenwei provides estimated lead times based on order details.

The latest trends for automatic packing machine for food products

Best Combination Weigher Models for Small Food Plants 2025

Top 10 multihead weigher Manufacturers and Supplier Brands in America

The B2B Buyer’s Guide to vertical form fill seal machine

About After Sales Support

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

About Solution suggestions

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

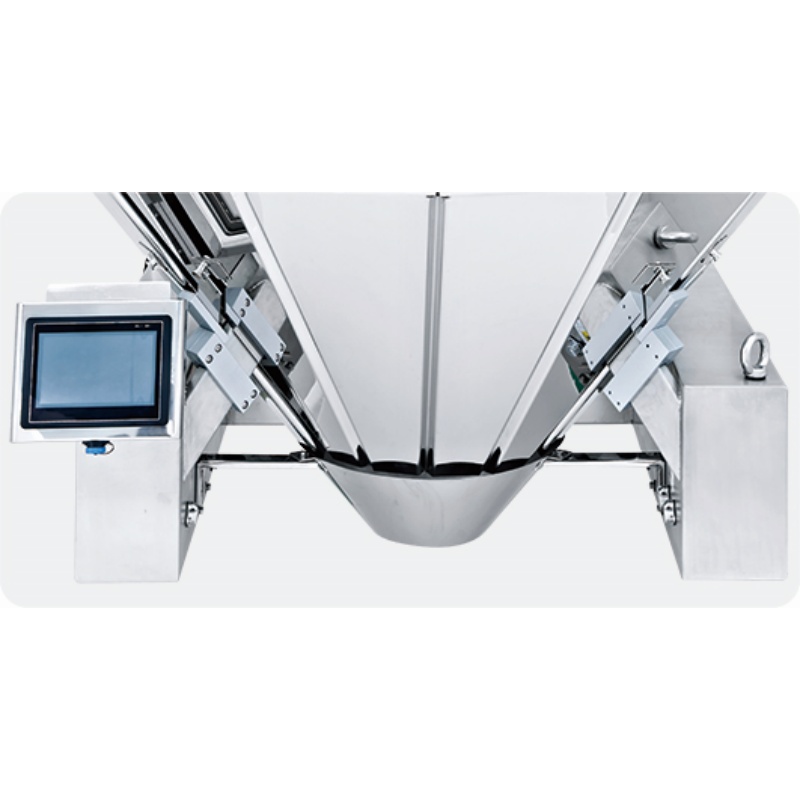

Multi Head Combination Weigher with Intelligent Feeding Control

Kenwei Multi Head Combination Weigher with Intelligent Feeding Control ensures high-speed, precise, and efficient weighing. Ideal for food and non-food industries, this advanced combination weigher boosts productivity and accuracy for all your multihead weigher needs.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei