Integration with Production Line Controls and Traceability

- Integration with Production Line Controls and Traceability: Why It Matters for a metal detector for food industry

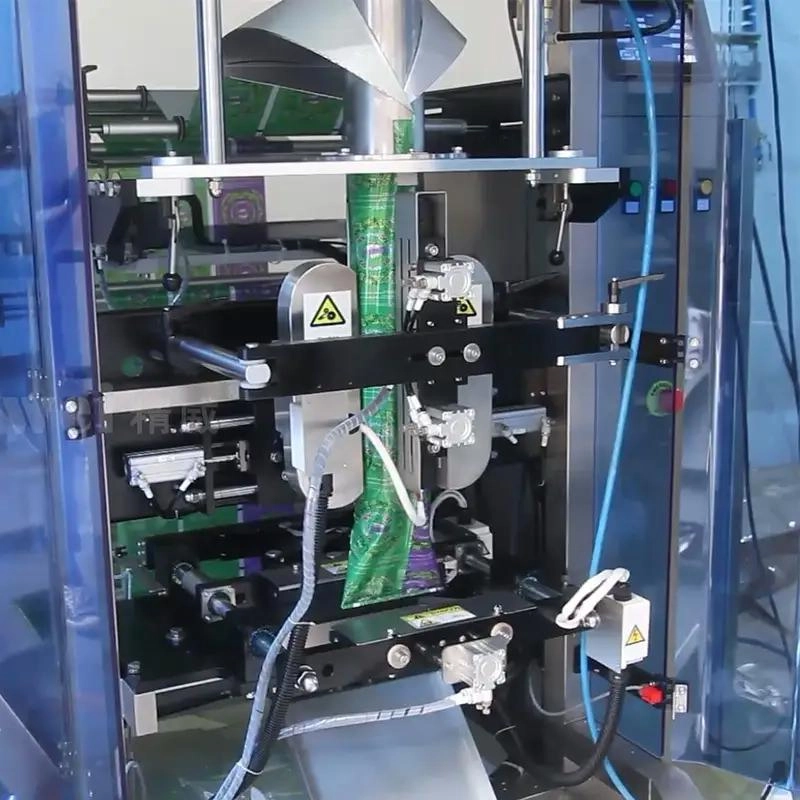

- Overview of the Food Metal Detector Manufacturer For Reject Defective Products G5020

- Why the G5020 is suited to integrated production environments

- Key integration goals when choosing a metal detector for food industry production

- Connectivity options: PLC, SCADA, and MES integration for metal detector for food industry

- Practical wiring and signals: what system integrators need to know

- Data logging and traceability: capturing the right events from your metal detector for food industry

- Validation and routine checks: proving that your metal detector for food industry works within the production line

- Reject mechanisms and containment strategy for metal detector for food industry

- Data formats and interoperability: making your metal detector for food industry speak enterprise language

- Performance metrics and KPIs to monitor from your metal detector for food industry

- Comparing typical metal detector features for integration: G5020 vs common alternatives

- Operational best practices to maximize integration benefits of your metal detector for food industry

- Brand advantages: Why choose our Food Metal Detector Manufacturer For Reject Defective Products G5020 for integrated lines

- FAQ: Frequently asked questions about integration and traceability for metal detector for food industry

- Q1: Can the G5020 connect directly to my existing PLC?

- Q2: How does the G5020 support traceability records for audits?

- Q3: What routine checks should operations perform to maintain sensitivity?

- Q4: Will integrating the detector slow my production line?

- Q5: Can the G5020 detect non-ferrous metals and stainless steel?

- Contact us / View product

- Authoritative references and further reading

Integration with Production Line Controls and Traceability: Why It Matters for a metal detector for food industry

Manufacturers in the food industry increasingly require metal detection systems that do more than simply sound an alarm. A modern metal detector for food industry production must integrate seamlessly with line controls and traceability systems to enable automated rejection, centralized monitoring, and reliable record keeping. This is crucial for protecting consumers, meeting regulations (HACCP, FSMA, ISO 22000), and minimizing costly product recalls. In this article we focus on practical integration strategies and traceability best practices using the Food Metal Detector Manufacturer For Reject Defective Products G5020 as a real-world example. With full system integration in place, manufacturers naturally evaluate the business impact. Our analysis of the ROI of installing G5020 metal detectors in food plants breaks down cost savings, recall prevention, and long-term value.

Overview of the Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Why the G5020 is suited to integrated production environments

The G5020 is built with multi-frequency detection for robust sensitivity across product types and incorporates mechanical design choices that facilitate hygienic production line integration. Its conveyor and modular frame reduce product snag points and simplify cleaning. For integrated systems, the G5020 supports common industrial interfaces and logical control signals that allow quick connection to PLCs, SCADA, and MES layers — enabling automated reject actions and real-time data exchange required in modern food plants.

Key integration goals when choosing a metal detector for food industry production

Successful integration is not only about electrical connections. The primary goals that production and quality teams seek are:

- Automated reject and containment to prevent contaminated product leaving the line.

- Reliable data capture for traceability, trending, and audit trail purposes.

- Minimal impact on line speed and uptime through reliable mechanical and electronic interfaces.

- Regulatory compliance support (HACCP, FSMA, ISO 22000) via validated performance and records.

Connectivity options: PLC, SCADA, and MES integration for metal detector for food industry

When integrating a metal detector like the G5020, consider three layers of factory systems:

- PLC (Programmable Logic Controller): Handles real-time I/O like start/stop, reject actuator control, and local interlocks.

- SCADA (Supervisory Control and Data Acquisition): Collects events, alarms, and simple trending; often uses OPC-UA, Modbus TCP/IP, or Ethernet/IP.

- MES (Manufacturing Execution System) and ERP: Responsible for batch and product traceability, quality records, and centralized reporting.

The G5020 supports digital I/O for immediate control (reject enable, reject active, alarm), and industrial communication protocols—commonly available as Modbus TCP/IP or Ethernet/IP modules—allowing real-time data to be streamed to SCADA and MES for traceability and analytics.

Practical wiring and signals: what system integrators need to know

Practical integration starts at the wiring panel. Typical signals you will wire between the G5020 and a PLC include:

- Input signals: Reset, Start/Stop, Product Present, Maintenance Mode.

- Output signals: Detect Alarm, Reject Trigger, Fault, System Ready.

Use solid-state relays or dry contacts for electrical isolation. Ensure signal debouncing is handled at PLC level to avoid false rejects. Also implement safety interlocks and permissive logic so that reject actuators cannot operate when a maintenance door is open or the conveyor is stopped.

Data logging and traceability: capturing the right events from your metal detector for food industry

Traceability requirements vary by market and product. At minimum, integrate the following event data from your metal detector into your traceability system:

- Time-stamped detect events (date/time, line ID, product code).

- Reject action and status (successful, failed, manual intervention).

- Operator ID and reason code for manual rejects or overrides.

- Machine health and calibration logs (sensitivity checks, verification tests).

The G5020 provides event logging that can be exported or polled by an MES. For audit readiness, retain logs with immutable timestamps and ensure secure storage aligned with site retention policies.

Validation and routine checks: proving that your metal detector for food industry works within the production line

Validation and ongoing verification are central to compliance and product safety. A practical validation process includes:

- Initial factory acceptance tests and on-site commissioning under actual production conditions.

- Sensitivity checks using standardized test pieces (ferrous, non-ferrous, stainless) performed at defined intervals.

- Documented calibration and maintenance records integrated into the traceability system.

Design the validation plan with QA and operations, and export G5020 test records automatically to your MES to reduce manual paperwork and human error.

Reject mechanisms and containment strategy for metal detector for food industry

Integration should include not only the signal to reject but also a robust containment and retrieval workflow. Reject options include pneumatic pushers, air blasts, drop flaps, and diverter arms. The right mechanism depends on product type and speed. The integration plan should also define:

- How rejected product is routed and segregated.

- How rejects are inspected and dispositioned (rework, discard).

- Traceability linkage so rejected batch or lot identifiers are recorded with the detect event.

For potentially high-volume rejects, add buffer conveyors and jam detection to avoid line blockages. The G5020 supports external reject control outputs and can be paired with interlocks to pause upstream lines when containment thresholds are exceeded.

Data formats and interoperability: making your metal detector for food industry speak enterprise language

Interoperability is eased by using standard data models and protocols. Recommended practices include:

- Use OPC-UA or MQTT for modern IIoT/Industry 4.0-ready communication.

- Adopt GS1 barcodes or serialized IDs for product/batch identification so detector events can be correlated to specific lots.

- Export logs in CSV or JSON for easy ingestion into analytics platforms and compliance reports.

Many installations use a gateway device to normalize data from legacy instruments into enterprise-friendly formats; the G5020's protocol options simplify that integration work.

Performance metrics and KPIs to monitor from your metal detector for food industry

Track KPIs that reflect both safety and productivity. Useful KPIs include:

- Number of detects per million units produced.

- False reject rate (percentage of rejects that were non-contaminant).

- MTTR (mean time to repair) for detector-related faults.

- Time to containment for detected events.

Send KPI summaries to dashboards and alert maintenance when thresholds are exceeded. The G5020's event logs provide the raw data to calculate these KPIs accurately.

Comparing typical metal detector features for integration: G5020 vs common alternatives

| Feature | G5020 | Typical Single-Frequency Detector |

|---|---|---|

| Detection sensitivity | Multi-frequency; robust across wet and packaged products; sensitivity suitable for sub-2mm fragments in many applications | Good for dry products; limited on wet or product-effect heavy lines |

| Hygienic design | Specialized conveyor belt, easy disassembly, designed to reduce contamination points | Often basic frame; may require more downtime for cleaning |

| Connectivity | Digital I/O + industrial Ethernet (Modbus/MQTT/optional Ethernet/IP) | Basic relay outputs; fewer protocol options |

| Traceability support | Built-in event logging, exportable to MES/SCADA | Limited local logging; manual records more common |

| Maintenance | Tool-free disassembly options; clear service workflows | May require tools and longer downtime |

Operational best practices to maximize integration benefits of your metal detector for food industry

To ensure integrated systems deliver expected value, apply these practices:

- Include QA, maintenance, and automation teams in specification and commissioning meetings.

- Standardize product codes and batch IDs across equipment and systems for easy correlation.

- Automate at-source logging: have the metal detector push event data to the MES immediately.

- Run simulated detect events during shift handovers to verify alarms and reject paths.

Brand advantages: Why choose our Food Metal Detector Manufacturer For Reject Defective Products G5020 for integrated lines

Our G5020 combines proven detection performance with design choices that simplify integration and validation. Key brand advantages include:

- Industry-focused engineering: multi-frequency detection tailored for diverse food products.

- Hygienic mechanical design: reduces cleaning time and cross-contamination risk.

- Flexible connectivity: supports modern and legacy protocols for easy PLC/SCADA/MES integration.

- Comprehensive documentation and validation support: IQ/OQ/PQ documentation and service packages to meet regulatory audits.

FAQ: Frequently asked questions about integration and traceability for metal detector for food industry

Q1: Can the G5020 connect directly to my existing PLC?

A1: Yes. The G5020 offers standard digital I/O for basic control and protocol modules (Modbus, Ethernet/IP, or Modbus TCP) for direct PLC/SCADA communication. Integration specifics depend on your PLC model and network configuration.

Q2: How does the G5020 support traceability records for audits?

A2: The G5020 logs detect events, rejects, calibration checks, and faults with timestamps and device identifiers. These logs can be exported or polled by an MES. We provide sample CSV and JSON export formats for easy ingestion into your traceability system.

Q3: What routine checks should operations perform to maintain sensitivity?

A3: Perform sensitivity verification with standard test pieces during start-of-shift or per your HACCP plan. Record each test in your MES. Also follow the G5020 maintenance schedule for belt condition and electronics checks.

Q4: Will integrating the detector slow my production line?

A4: Properly configured, the detector should not materially slow the line. Ensure reject timing and buffer sizing are matched to cycle speed. Use permissive logic to avoid unnecessary stops and implement high-speed reject mechanisms for fast lines.

Q5: Can the G5020 detect non-ferrous metals and stainless steel?

A5: Yes. Multi-frequency detection improves sensitivity to non-ferrous metals and difficult-to-detect stainless steel fragments compared to single-frequency detectors, though detection performance depends on product type, packaging, and fragment size.

Contact us / View product

If you are planning a production line integration or need help choosing the right reject and traceability strategy, contact our specialists. View the Food Metal Detector Manufacturer For Reject Defective Products G5020 product page or request a demo and integration consultation today.

Authoritative references and further reading

- U.S. Food & Drug Administration (FDA) — Food Safety Modernization Act (FSMA): https://www.fda.gov/food/food-safety-modernization-act-fsma

- Codex Alimentarius Commission — Food safety standards and guidelines: http://www.fao.org/fao-who-codexalimentarius

- ISO 22000 — Food safety management systems overview: https://www.iso.org/iso-22000-food-safety-management.

- BRC Global Standards — Food safety certification information: https://www.brcgs.com

- GS1 — Standards for traceability and identification in supply chains: https://www.gs1.org

- AOAC International — Methods and standards for analytical testing: https://www.aoac.org

The latest trends for multi head packing machine

What are the application scenarios of single head weigher?

Top 10 automatic packing machine Manufacturers and Supplier Brands

Energy, Maintenance, and Uptime: Procurement Guide to VFFS

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

How about the after-sales service?

Warranty :2 years

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

Dropped Metal Detector for Powder Granules For Food Industry

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei