How Metal Detectors for Food Packaging Ensure Product Safety and Quality

Metal detectors for food packaging are essential for ensuring product safety, detecting metal contaminants, and maintaining quality standards in food production. This article explains how they work, their components, applications, and best installation practices for maximum efficiency.

In the food production industry, packaging safety is critical to delivering products in a contamination-free condition. One essential piece of equipment in this process is the metal detector for food packaging. These devices detect unwanted metal objects—such as nails, staples, or fragments—ensuring that food products reach consumers in perfect condition.

What is a Metal Detector for Food Packaging?

A metal detector for food packaging is designed to identify any metal contaminants within packaged food products. This is crucial for high-risk products like canned foods, meat, and dairy. Metal detectors are commonly used in production facilities, warehouses, retail stores, and restaurants—often alongside other inspection tools such as X-ray machines.

Working Principle

The operating principle of a food packaging metal detector is straightforward:

-

The machine sends out a magnetic field that reacts to metallic particles.

-

The presence of metal disrupts this magnetic field, triggering the detection system.

-

The signal is processed by the electronics, which then alerts operators or activates an automatic rejection system.

Some advanced models also use sound wave technology for deeper detection, making them effective for products where metals may be embedded inside the packaging.

Key Components of a Metal Detector for Food Packaging

1. Detector Coil

The detector coil is the heart of the system, made of three parallel coils.

-

The central coil (transmitter) generates a high-frequency magnetic field.

-

The two receiver coils are connected in reverse, creating a zero-output balance when no metal is present.

-

If metal enters, this balance is disturbed, generating a detectable signal.

This design ensures stability against temperature changes, vibrations, and electromagnetic interference.

2. Control Panel

The user interface—often a touch screen or button panel—is mounted on or near the coil. In tight spaces, it can be installed remotely via cables for easier operation.

3. Transmission System

The transmission system moves products through the detection area.

-

Common types include horizontal conveyor belts for packaged goods, gravity-drop systems for powders or granules, and inline systems for liquids.

-

Special channels are also used in pharmaceutical packaging.

4. Automatic Rejection System

Once metal is detected, an automatic rejection system removes the contaminated product from the line. Methods include blowers, pushers, and flaps—selected based on the type of food being tested.

Applications

Metal detectors in food packaging serve multiple purposes:

-

Detect sharp or dangerous metal fragments that could cause injury.

-

Identify counterfeit or substandard goods.

-

Maintain compliance with food safety regulations.

-

Protect brand reputation and consumer trust.

Best Installation Locations

To maximize efficiency, metal detectors for food packaging should be installed:

-

At the end of the production line, before final packaging.

-

In receiving areas to check incoming raw materials.

-

In storage areas to monitor stored products before shipping.

Conclusion

Metal detectors for food packaging are a vital part of food safety inspection and quality control in the food production industry. They not only detect harmful contaminants but also protect brand integrity and ensure compliance with safety regulations.

Guangdong Kenwei Intellectualized Machinery Co. is a leading manufacturer of advanced weighing and packaging systems. Our high-precision multihead weighers and metal detection systems are trusted by major brands worldwide, helping businesses deliver safe, high-quality products.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

About products customization

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About Price and payment

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

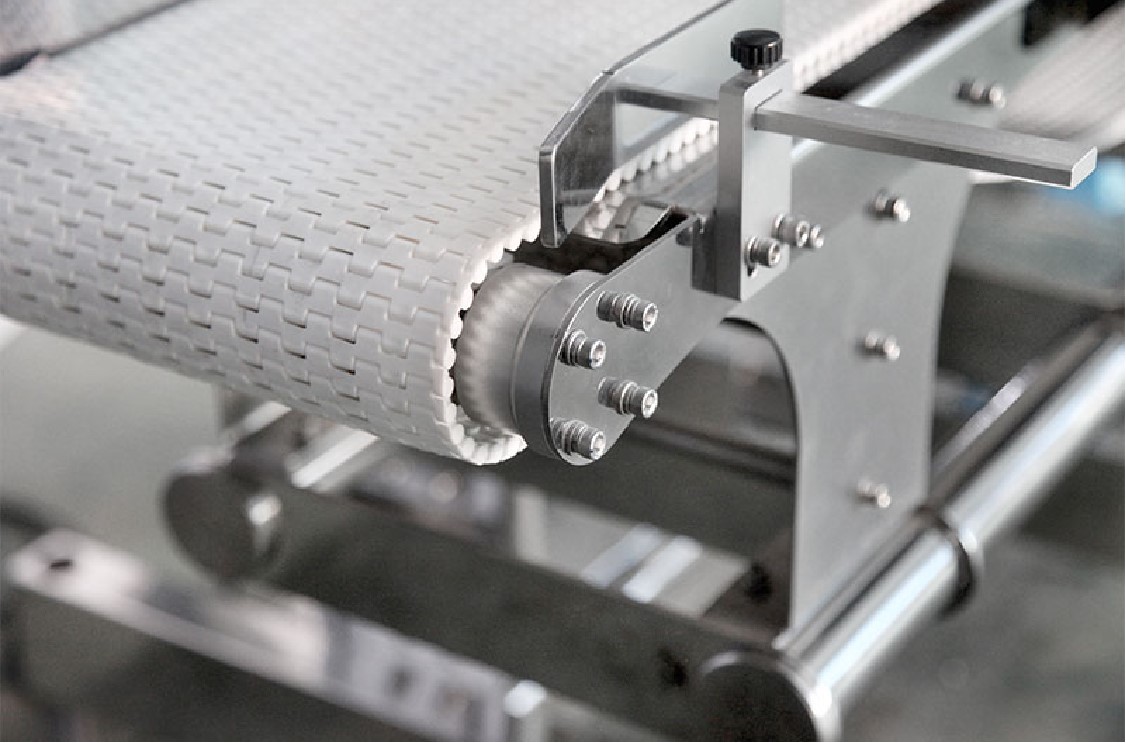

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei