How to Select the Right Multihead Weigher for Your Production Line

- 1. Start With a Clear Understanding of Your Product Behavior

- 2. Plan the Required Line Capacity

- 3. Focus on Accuracy to Minimize Waste and Maintain

- 4. Match the Weigher to Your Hygiene and Environmental Standards

- 5. Ensure Smooth Integration With the Whole Packaging Line

- 6. Evaluate Long-Term ROI Instead of Initial

- 7. Prioritize After-Sales Support and Technical Expertise

- 8. Conclusion

For manufacturers designing or upgrading a packaging line, choosing the right multihead weigher goes far beyond selecting a machine with the right number of heads. A well-chosen weigher becomes a central driver of efficiency, accuracy, and sustainable cost control. With options ranging from compact 10-head units to high-performance 32-head systems, the challenge lies in matching the machine’s capabilities to real production conditions. This guide reframes the selection process from a system-level viewpoint and highlights why Guangdong Kenwei Intellectualized Machinery Co., Ltd. is a preferred partner for factories worldwide.

1. Start With a Clear Understanding of Your Product Behavior

Every product behaves differently during feeding, weighing, and discharge, so the weigher must be matched to its physical characteristics.

Consider: Type and flowability: granular, powdery, fragile, sticky, or irregular shapes.

- Weight and size variation: high-consistency or high-variability products.

- Moisture and oil content: may require anti-stick or special surface treatments.

- Fragility: snacks such as chips and cookies require gentle handling solutions.

Accurate knowledge of product behavior guides decisions on hopper structure, vibration settings, and algorithm tuning.

2. Plan the Required Line Capacity

Not Just Machine Speed Production goals differ across facilities. The weigher must align with the desired throughput of your entire packaging line:

- Small operations: 20–50 bags/min

- Mid-size manufacturers: 80–150 bags/min

- High-speed lines: 200+ bags/min

Weigher configurations—10, 14, 16, 24, or 32 heads—directly influence combination possibilities and, therefore, output speed. Kenwei provides configurations optimized for every level of production, ensuring stable accuracy even at high speeds.

3. Focus on Accuracy to Minimize Waste and Maintain

Compliance Weighing precision is one of the biggest contributors to cost savings. Key factors include:

- Sensor quality: digital load cells outperform analog sensors.

- Algorithm optimization: intelligent combination algorithms reduce giveaway.

- Calibration maintenance: ensures long-term consistency.

Kenwei’s multihead weighers use premium digital load cells and advanced algorithms designed to keep product giveaway exceptionally low.

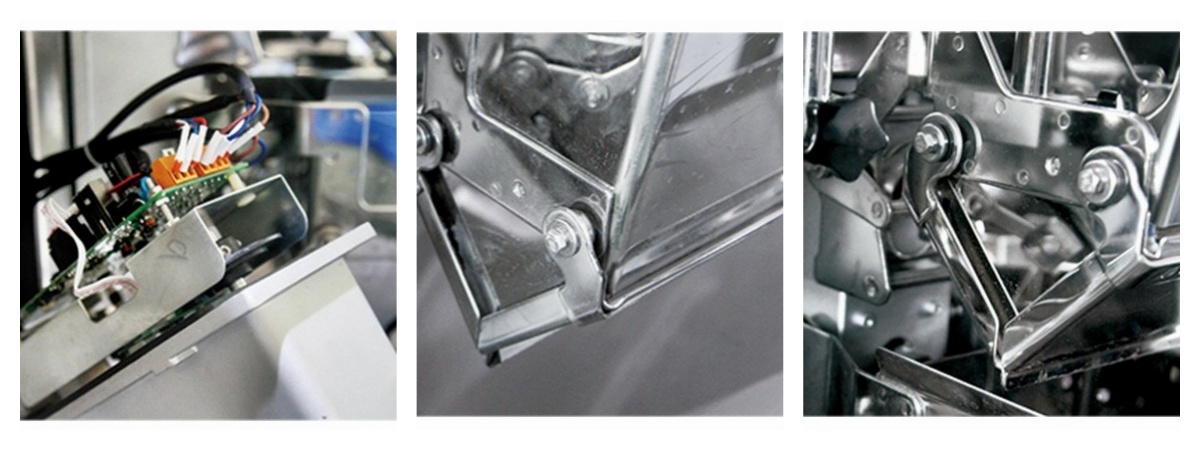

4. Match the Weigher to Your Hygiene and Environmental Standards

Different environments impose different equipment requirements. Consider:

- Material selection: 304/316 stainless steel for food-grade or pharmaceutical use.

- Protection levels: IP65 or IP67 for dusty, wet, or frozen working conditions.

- Cleaning convenience: tool-less design and modular components reduce downtime.

Kenwei’s structural designs prioritize sanitation, durability, and easy maintenance across food, chemical, and pharmaceutical sectors.

5. Ensure Smooth Integration With the Whole Packaging Line

A multihead weigher is just one link in a complete packaging system. Proper integration ensures uninterrupted flow with:

- VFFS machines

- Premade pouch systems

- Conveyors, metal detectors, checkweighers

Kenwei offers tailored integration services to ensure the weigher synchronizes perfectly with upstream and downstream equipment.

6. Evaluate Long-Term ROI Instead of Initial

Cost The most cost-effective option is not always the cheapest upfront.

Consider:

- Energy consumption

- Spare parts and maintenance costs

- Savings from reduced product giveaway

Machine durability and lifespan Kenwei designs its machines for long-term reliability and stable performance, ensuring a strong return on investment.

7. Prioritize After-Sales Support and Technical Expertise

Reliable service ensures your production line stays operational. Kenwei provides:

Global technical support

On-site installation and commissioning

Remote diagnostics and troubleshooting

Operator training for optimal performance

A solid service network reduces downtime and operational risk.

8. Conclusion

Selecting a multihead weigher is a strategic decision that affects the entire production chain. By evaluating product characteristics, speed requirements, precision needs, hygiene standards, integration compatibility, and long-term ROI, manufacturers can ensure they choose a solution that enhances efficiency and profitability. For companies seeking dependable, high-accuracy, and customizable weighing equipment, Guangdong Kenwei Intellectualized Machinery Co., Ltd. delivers industry-leading performance backed by comprehensive support. With Kenwei’s expertise, factories can achieve higher throughput, reduced waste, and sustainable long-term success across both food and non-food packaging applications.

![7-Cutting-Edge-Food-Packaging-Machine-Trends-That-Will-Dominate-in-2026-[Expert-Analysis] - Kenwei 7 Cutting-Edge Food Packaging Machine Trends That Will Dominate in 2026 [Expert Analysis] - Kenwei](https://static.gooecloud.com/upload/img/GY642003619875/7-cutting-edge-food-packaging-machine-trends-that-will-dominate-in-2026-expert-analysis.png?x-oss-process=image/format,webp/quality,Q_100)

About Product choice

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About Solution suggestions

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei