The latest trends for multi head packing machine

- The Latest Trends for Multi Head Packing Machine in 2025

- 1. Automation Driving Efficiency in Multi Head Packing Machines

- 2. Smart Technology and IoT in Multi Head Packing Machines

- 3. Sustainability Focus in Multi Head Packing Machine Design

- 4. Customization for Diverse Industry Needs with Multi Head Packing Machines

- 5. Enhanced Precision and Speed in Multi Head Packing Machines

- 6. Integration of AI and Machine Learning in Multi Head Packing Machines

- 7. Growth in Market Demand for Multi Head Packing Machines

- 8. Focus on User-Friendly Interfaces for Multi Head Packing Machines

- 9. Conclusion: Staying Ahead with Multi Head Packing Machine Trends

The Latest Trends for Multi Head Packing Machine in 2025

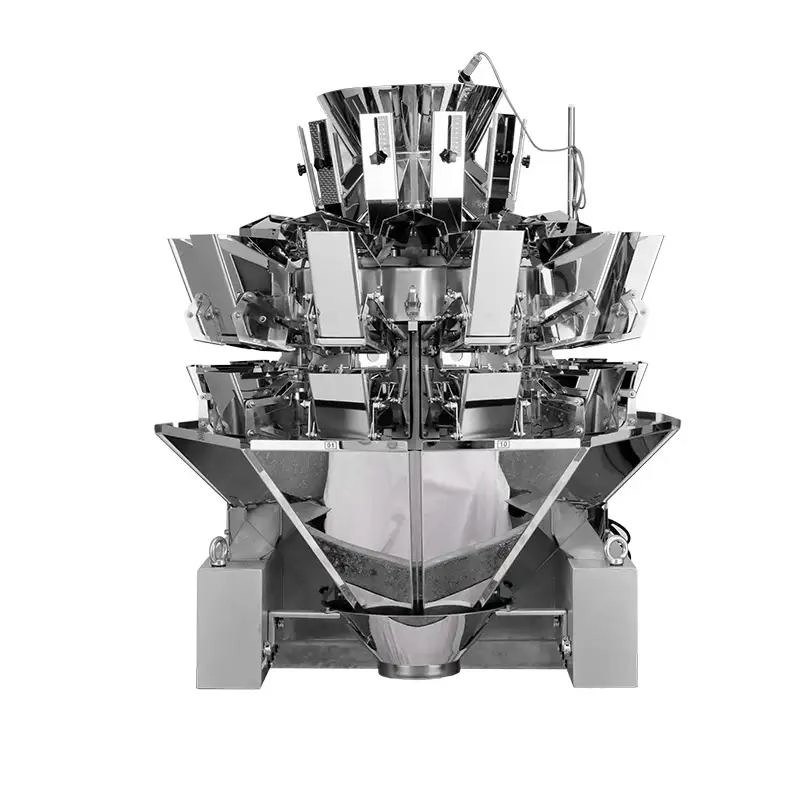

As the packaging industry continues to evolve, businesses are increasingly relying on advanced technology to meet growing demands for speed, precision, and efficiency. At the forefront of this transformation is the multi head packing machine, a vital tool for industries like food, pharmaceuticals, and consumer goods. As a leading manufacturer, Kenwei is dedicated to staying ahead of the curve by integrating the latest trends into our high-speed, high-precision multi-head weighers and automated packaging solutions. Located in Zhongshan City, Guangdong Province, at Fusha High-tech Industrial Park, Kenwei offers comprehensive services from design to after-sales support, ensuring tailored solutions for every customer. In this blog, we dive into the most significant trends shaping the multi head packing machine industry in 2025 and how they can benefit your business.

1. Automation Driving Efficiency in Multi Head Packing Machines

Automation remains a game-changer in the packaging sector, and its integration into multi head packing machine technology is accelerating in 2025. Automated systems reduce manual intervention, minimize errors, and speed up production lines. At Kenwei, our multi-head weighers are designed to seamlessly integrate with automated weighing and packaging systems, ensuring high output with minimal downtime. This trend is particularly crucial for industries handling high-volume production, as automation helps meet tight deadlines while maintaining consistency. Investing in an automated multi head packing machine can significantly cut labor costs and boost your operational efficiency.

2. Smart Technology and IoT in Multi Head Packing Machines

The rise of smart technology and the Internet of Things (IoT) is transforming how businesses operate, and the multi head packing machine industry is no exception. In 2025, more machines are equipped with IoT capabilities, allowing real-time monitoring, predictive maintenance, and data analysis. Kenwei’s advanced multi-head weighers come with smart features that let you track performance metrics and detect issues before they cause downtime. This technology ensures that your multi head packing machine operates at peak performance, reducing waste and improving decision-making through actionable insights. For businesses looking to stay competitive, adopting IoT-enabled machines is a smart move.

3. Sustainability Focus in Multi Head Packing Machine Design

Sustainability is no longer just a buzzword; it’s a priority for businesses worldwide. In 2025, the multi head packing machine industry is seeing a shift towards eco-friendly designs that minimize energy consumption and support sustainable packaging materials. At Kenwei, we are committed to developing machines that optimize resource use while maintaining high precision. Our multi-head weighers help reduce product waste during packaging, aligning with global efforts to cut down on environmental impact. For companies aiming to meet sustainability goals, choosing a multi head packing machine with energy-efficient features is a step in the right direction.

4. Customization for Diverse Industry Needs with Multi Head Packing Machines

Every industry has unique packaging requirements, and customization is a growing trend in the multi head packing machine market. Whether you’re in food processing, pharmaceuticals, or hardware, having a machine tailored to your specific needs is essential. Kenwei excels in providing one-stop automated weighing and packaging solutions, offering customizable multi-head weighers, linear weighers, and check weighers to match your production goals. In 2025, the demand for versatile multi head packing machines that handle various product types and packaging formats continues to rise. Partnering with a manufacturer like Kenwei ensures your equipment aligns perfectly with your operational demands.

5. Enhanced Precision and Speed in Multi Head Packing Machines

Precision and speed have always been the core strengths of a multi head packing machine, and advancements in 2025 are taking these capabilities to new heights. With consumer expectations for faster delivery and consistent quality growing, manufacturers are under pressure to deliver. Kenwei’s multi-head weighers are engineered for high-speed operations without compromising accuracy, ensuring every package meets exact weight specifications. This trend is critical for industries like snacks and frozen foods, where even slight deviations can impact profitability. Upgrading to a high-precision multi head packing machine can enhance your product quality and customer satisfaction.

6. Integration of AI and Machine Learning in Multi Head Packing Machines

Artificial Intelligence (AI) and machine learning are making waves in the packaging industry, with significant implications for the multi head packing machine sector in 2025. These technologies enable machines to adapt to changing production conditions, optimize weighing processes, and predict maintenance needs. While Kenwei is continuously exploring AI integration, many modern multi-head weighers in the market are beginning to adopt these innovations to improve efficiency. For businesses, investing in an AI-powered multi head packing machine means staying ahead of competitors by leveraging cutting-edge technology to streamline operations.

7. Growth in Market Demand for Multi Head Packing Machines

The global demand for packaging machinery, including multi head packing machines, is on a steady rise. According to recent industry reports, the packaging machinery market was valued at USD 50.08 billion in 2024 and is projected to reach USD 78.75 billion by 2034, growing at a CAGR of 4.63%. Specifically, the multihead weigher packing machine market is expected to grow from USD 0.239 billion in 2025 to USD 0.377 billion by 2033 at a CAGR of 6.7%. At Kenwei, we are poised to meet this growing demand by offering reliable, high-performance machines. Businesses looking to scale operations should consider investing in a multi head packing machine to capitalize on this expanding market.

8. Focus on User-Friendly Interfaces for Multi Head Packing Machines

As technology advances, so does the need for user-friendly systems. In 2025, a key trend in the multi head packing machine industry is the development of intuitive interfaces that simplify operation and training. Kenwei’s machines are designed with easy-to-use controls, allowing operators to manage complex processes with minimal learning curves. This focus on usability ensures that businesses can quickly adapt to new equipment, reducing setup time and improving productivity. If you’re in the market for a multi head packing machine, prioritize models with accessible interfaces to maximize efficiency.

9. Conclusion: Staying Ahead with Multi Head Packing Machine Trends

The multi head packing machine industry is evolving rapidly, driven by automation, smart technology, sustainability, and customization. As a trusted manufacturer, Kenwei is committed to leading the way by delivering innovative, high-speed, and precise solutions that meet the diverse needs of our clients. Whether you’re looking to enhance efficiency, reduce environmental impact, or scale your operations, staying updated with these 2025 trends is essential. Based in Guangdong Province, we at Kenwei aim to become the world’s leading weighing and packing machine manufacturer, and we invite you to partner with us to achieve your business goals. Explore our range of multi-head weighers and automated solutions at kenweigroup.com to see how we can help you stay competitive in this dynamic industry.

Frequently Asked Questions (FAQs)

What is a multi head packing machine?

A multi head packing machine is a specialized equipment used for weighing and packaging products with high speed and accuracy. It uses multiple heads to weigh items simultaneously, ensuring consistent portions for industries like food, pharmaceuticals, and more.

Why should I invest in a multi head packing machine for my business?

Investing in a multi head packing machine boosts production efficiency, reduces labor costs, and ensures precise packaging. It’s ideal for businesses handling large volumes and needing consistent quality, helping you meet customer demands effectively.

How does automation benefit multi head packing machines?

Automation in multi head packing machines minimizes human error, speeds up processes, and lowers operational costs. It allows seamless integration into production lines, ensuring consistent output with minimal downtime for your business.

Are multi head packing machines customizable?

Yes, many manufacturers like Kenwei offer customizable multi head packing machines to meet specific industry needs. Whether it’s for different product types or packaging formats, tailored solutions ensure optimal performance for your operations.

How can I learn more about Kenwei’s multi head packing machine solutions?

Visit our website at https://www.kenweigroup.com/ to explore our range of multi-head weighers and automated packaging systems. Contact us directly for personalized assistance and to discuss your specific requirements with our team.

The B2B Buyer’s Guide to vffs bagging machine

How to Integrate a Food Metal Detector with Multihead Weighers

How to Validate and Test Food Metal Detectors Effectively

How Sensitivity Affects Food Metal Detector Performance

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

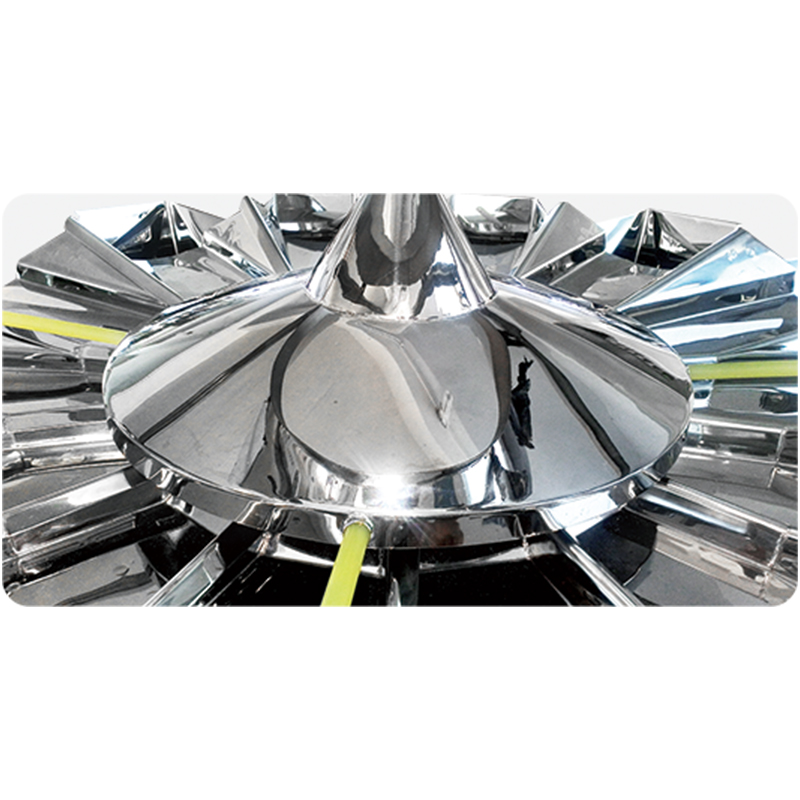

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

14-Head High-Speed Springless Multihead Weigher for Accurate Weighing

The high-speed weigher features a new spring-free aluminum shell design with double chute feeding and dual high-speed hopper alternating feeding, significantly boosting feeding speed. It is ideal for weighing materials such as melon seeds, peanuts, nuts, almonds, raisins, candy, pistachios, and more. The 18-head high-speed weigher is equipped with 2L hoppers, achieving a maximum weighing speed of up to 180 bags per minute.

16-Head Multihead Weigher with 1.6L Three-Layer Hopper for Accurate Weighing

The Kenwei 16-Head Multihead Weigher with a 1.6L Three-Layer Hopper provides precise and efficient weighing with a maximum speed of 240 packs per minute, optimizing your production line. The main vibrating pan supports two types of mixed materials, offering versatility and consistent performance. This advanced multihead packing machine is ideal for a wide range of products, including nuts, raisins, candies, potato chips, and other snack foods, as well as hardware and plastic materials. It ensures reliable performance and high accuracy in various industries.

10 Heads Leak Proof Multihead Weigher With 3L Hoppers

The 10-head multihead weigher features a leak-proof design that prevents material leakage and ensures optimal hygiene. Equipped with 3L hoppers, it accurately weighs a wide range of products, including powders and granules. The high-speed multihead weigher delivers fast, precise weighing to improve production efficiency. With a user-friendly interface for easy operation and adjustments, and a durable stainless steel frame, it offers long-lasting reliability and performance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei