Energy, Maintenance, and Uptime: Procurement Guide to VFFS

- Energy, Maintenance, and Uptime: Procurement Guide to VFFS

- Why choose a vertical packaging machine for modern production lines?

- About the Economic vertical form fill seal packing machine (VFFS)

- Energy efficiency considerations when procuring a vertical packaging machine

- How energy impacts lifecycle cost

- Maintenance planning: design features that simplify repair

- Planned vs. unplanned maintenance: budgeting implications

- Maximizing uptime: mechanical and operational best practices

- Spare parts, service contracts and local support for vertical packaging machine procurement

- Comparing VFFS models: energy, maintenance and uptime (quick reference)

- Procurement checklist: questions to ask suppliers of vertical packaging machines

- Total cost of ownership (TCO) model and ROI considerations

- Operational tips to reduce energy and maintenance burdens

- Brand advantages: why choose our Economic vertical form fill seal packing machine (VFFS)

- ROI example: how small improvements compound

- FAQs

- Q: How much power does a typical Economic vertical form fill seal packing machine use?

- Q: What maintenance schedule should we expect?

- Q: How quickly can a VFFS be repaired during a breakdown?

- Q: Can the Economic VFFS handle frozen foods and fragile products?

- Q: How do safety features affect maintenance access?

- Q: What warranty and service contract options should I expect?

- Contact us / View product

- Authoritative references

Energy, Maintenance, and Uptime: Procurement Guide to VFFS

Why choose a vertical packaging machine for modern production lines?

Vertical packaging machines (also called VFFS machines) are widely used in food, snack, coffee, grains, frozen foods, and small-parts industries because they combine speed, flexibility and compact footprint. When procurement teams evaluate a vertical packaging machine they’re not buying a single piece of equipment — they’re investing in ongoing energy costs, maintenance regime, spare parts strategy, and achievable uptime. This guide focuses on the three factors that most directly impact total cost of ownership (TCO): energy, maintenance, and uptime. Understanding trade-offs in these areas lets you select the right Economic vertical form fill seal packing machine (VFFS) for your product mix and operational goals.

About the Economic vertical form fill seal packing machine (VFFS)

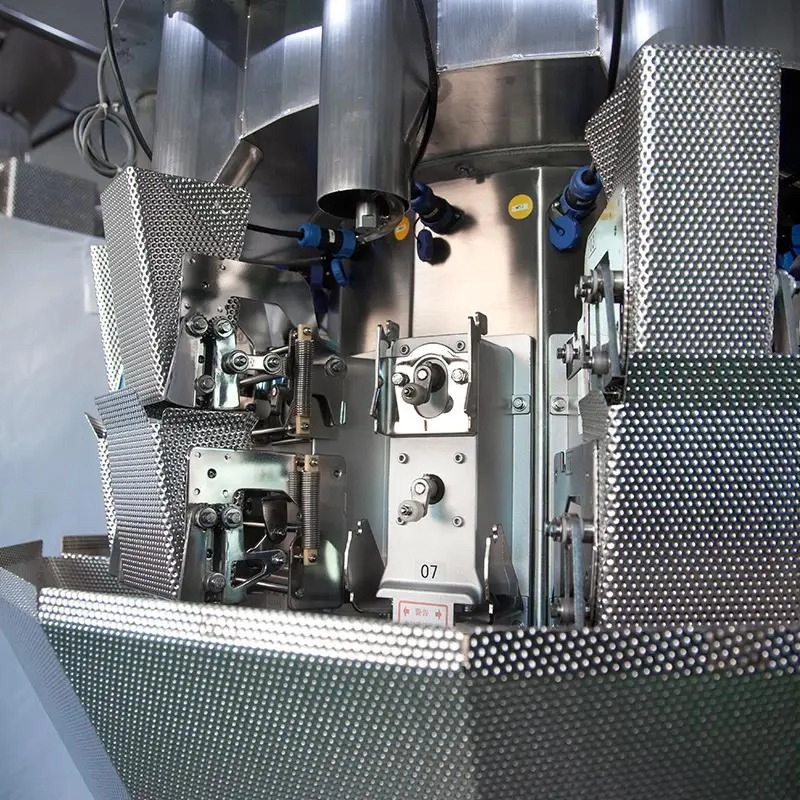

The economical vertical form fill seal (VFFS) packaging machine offers a variety of models designed with a sturdy 304 stainless steel frame. It is equipped with safety door protection and supports multiple bag types, including pillow bags, angle belt bags, printed bags, and triangle bags. This versatile machine is ideal for packaging a wide range of materials, such as snacks, frozen foods, coffee beans, oats, sugar, salt, rice, small hardware components, and more. Affordable and cost-effective, it provides reliable performance and efficiency for diverse packaging needs.

Energy efficiency considerations when procuring a vertical packaging machine

Energy consumption is often overlooked at purchase time but quickly appears in monthly operating budgets. When assessing VFFS options, consider:

- Motor and drive technology: Servo drives typically deliver better energy efficiency and more precise control than older stepper or AC motor systems. They also reduce film waste through improved bag-length repeatability.

- Heating system type: Cutting and sealing systems (e.g., hot jaws, rotary sealers) dominate energy use. Machines with on-demand heating, PID control and fast recovery consume less power overall than constant-ON heaters.

- Standby and smart-sleep features: Machines that can enter low-power standby during breaks reduce idle energy consumption without sacrificing quick restart.

- Ancillary equipment footprint: Vacuum pumps, gas flush systems, and cooling fans add to energy draw. Choose configurations that match your product needs rather than default add-ons.

- Energy monitoring and meters: Built-in power meters give procurement teams hard data for validation and future optimization.

How energy impacts lifecycle cost

Example: a VFFS that draws 6 kW at full production vs a modern servo-driven VFFS drawing 4 kW. If both run 2,000 hours per year at $0.12/kWh, annual energy cost differences matter:

| Metric | Older VFFS (6 kW) | Efficient VFFS (4 kW) |

|---|---|---|

| Annual hours | 2,000 | 2,000 |

| Annual energy (kWh) | 12,000 | 8,000 |

| Annual energy cost ($0.12/kWh) | $1,440 | $960 |

| Annual savings | $480 | |

Over a 5–10 year life, savings compound and can offset higher upfront cost of energy-efficient models.

Maintenance planning: design features that simplify repair

Maintenance strategy drives uptime. Machines designed for accessibility and fast service reduce mean time to repair (MTTR) and maintenance labor costs. When evaluating vendors of vertical packaging machines, look for:

- Modular components and quick-release belts/sleeves for fast changeover.

- Clear access doors and safety interlocks that do not require tools to release panels while following lockout/tagout (LOTO) rules.

- Commonality of consumables and wear parts across model families (fewer SKUs to stock).

- Built-in diagnostics and fault codes that guide technicians to root causes quickly.

- Vendor-provided preventive maintenance (PM) schedules and spare parts kits aligned to runtime.

Planned vs. unplanned maintenance: budgeting implications

Planned maintenance prevents many failures but requires downtime. Unplanned failures are more disruptive and expensive. When comparing Economic vertical form fill seal packing machine (VFFS) models, request historical MTBF (mean time between failures) and average MTTR (mean time to repair) from similar installations. Use those figures to model expected downtime, labor cost, and spare parts spend.

Maximizing uptime: mechanical and operational best practices

Uptime is influenced by machine design and how people operate it. Key practices include:

- Operator training: Regular, role-specific training (changeover, cleaning, troubleshooting) shortens downtimes and reduces human error.

- Standardized changeover procedures and tool kits: Reduce variability and speed bag format changes.

- Scheduled PM: Daily checks, weekly lubrication, and monthly inspections that follow vendor schedules prevent wear-related failures.

- Use of condition-monitoring sensors: Vibration, temperature and motor-current sensing catch degradation before failure.

- Shift handover logs: Capture issues so night shift teams address small problems before they grow.

Spare parts, service contracts and local support for vertical packaging machine procurement

Procurement must account for spare part availability and service network. Consider:

- Critical spare parts list: cutters, sealing jaws, belts, bearings, sensors. Ask vendors for recommended spares to keep on-site.

- Service level agreements (SLAs): Response times and remote support options (phone, video, remote PLC/HMI access).

- Local partners and certified technicians: Local presence reduces travel time and cost for emergency repairs.

- Training offerings: On-site or virtual training as part of purchase or annual support packages.

- Firmware and software update policies: Regular updates can improve efficiency and security — confirm the vendor’s approach and any subscription fees.

Comparing VFFS models: energy, maintenance and uptime (quick reference)

| Feature | Basic Economy VFFS | Efficient Servo VFFS | High Quality Fully-Automated VFFS |

|---|---|---|---|

| Typical power draw | 4–6 kW | 3–4 kW | 3–5 kW |

| Primary drive | AC/stepper | servo | servo with regen |

| Heating control | basic on/off | PID on-demand | PID + zoned control |

| Expected MTBF | 6,000–10,000 hrs | 10,000–20,000 hrs | 15,000+ hrs |

| Typical downtime per year | 80–200 hrs | 40–120 hrs | 20–60 hrs |

| Maintenance complexity | Low–Medium | Medium | Medium–High |

| CapEx | Low | Medium | High |

Procurement checklist: questions to ask suppliers of vertical packaging machines

Use this checklist during RFQs and factory acceptance tests:

- Can you provide measured energy consumption at typical production speeds?

- What are the MTBF and MTTR numbers for installations similar to ours?

- Which components are considered wear parts and what are lead times for spares?

- Do you offer remote diagnostics and what does that service cost?

- What safety features and certifications does the machine include (CE, UL, ISO)?

- Is the machine compatible with our multihead weigher or other upstream feeders?

- Do you provide operator and maintenance training as part of purchase?

- What warranties and optional service contracts are available?

Total cost of ownership (TCO) model and ROI considerations

TCO includes purchase price, energy, consumables, planned maintenance labor, spare parts, and unplanned downtime. An ROI model should include realistic throughput assumptions, scrap rates, labor costs and energy prices. Below is a simple annualized example comparing two options across 5 years.

| Metric | Basic VFFS | Efficient VFFS |

|---|---|---|

| CapEx | $25,000 | $40,000 |

| Annual energy | $1,500 | $1,000 |

| Annual maintenance & spares | $4,000 | $3,000 |

| Annual downtime cost (lost production) | $10,000 | $6,000 |

| 5-year total cost (CapEx + 5*(Opex)) | $25,000 + 5*($15,500) = $102,500 | $40,000 + 5*($10,000) = $90,000 |

In this simplified example, the higher initial investment in the efficient model pays back through lower Opex and less downtime.

Operational tips to reduce energy and maintenance burdens

- Optimize production scheduling to reduce start/stop cycles — long continuous runs are more energy-efficient.

- Match machine speed to downstream capacity (e.g., multihead weighers) to avoid unnecessary throttling or idle time.

- Keep a small, prioritized inventory of critical wear parts for rapid swap and minimal downtime.

- Implement simple condition monitoring: record run hours, track vibration/heat, and log minor faults before they escalate.

- Perform root-cause analysis after failures to prevent recurrence and refine PM procedures.

Brand advantages: why choose our Economic vertical form fill seal packing machine (VFFS)

When you evaluate brands, look for alignment across performance, service and cost-efficiency. The Economic VFFS offers:

- Sturdy 304 stainless steel construction suitable for food and many industrial environments, supporting hygienic cleaning and long life.

- Support for multiple bag types — pillow, angle belt, printed and triangle bags — reducing the need for separate machines.

- Safety door protection and straightforward HMI for fast operator learning and safer maintenance access.

- Cost-effective pricing and configurations that let small and mid-sized operations access modern VFFS capabilities without investing in unnecessary high-end features.

- Compatibility with a wide range of upstream feeders including multihead weighers and auger fillers, enabling integration into existing lines.

ROI example: how small improvements compound

Small changes can yield significant returns. If optimized heating control and servo adoption reduce scrap/failures by 1% and downtime by 20% on a line that produces $1.5M annually, savings can quickly justify an incremental investment in a more capable VFFS. Always run site-specific scenarios with accurate throughput and cost inputs before final decisions.

FAQs

Q: How much power does a typical Economic vertical form fill seal packing machine use?

A: Typical power draw ranges 3–6 kW depending on configuration, sealing system and ancillary equipment. Confirm measured power at vendor factory acceptance tests (FAT).

Q: What maintenance schedule should we expect?

A: Daily cleaning and visual checks, weekly lubrication and belt inspections, and monthly detailed inspections are common. Follow vendor PM schedule and align with production downtime windows.

Q: How quickly can a VFFS be repaired during a breakdown?

A: Simple repairs may take 15–60 minutes with trained staff and spares on-site. Complex electrical/control faults can take longer and may need remote vendor support. MTTR varies by model and support arrangements.

Q: Can the Economic VFFS handle frozen foods and fragile products?

A: Yes — with proper tooling, calibrated fill systems and gentle handling options (e.g., low-drop funnels, conveyor buffering), the machine can package frozen and fragile items. Discuss product-specific needs with the supplier.

Q: How do safety features affect maintenance access?

A: Modern safety interlocks and safety door protections allow safe access while ensuring compliance with regulations. Properly designed interlocks minimize tool requirements and allow faster service while still preserving worker safety.

Q: What warranty and service contract options should I expect?

A: Typical warranties cover 12 months for parts and labor; extended warranties and service contracts (including scheduled PM, priority support, and parts discounts) are commonly offered. Negotiate SLAs that match your production risk tolerance.

Contact us / View product

Beyond machine reliability, buyers must ensure smooth operation by confirming packaging material compatibility for vertical packaging machines across different film types.If you want a tailored proposal, on-site audit, or to schedule a factory acceptance test for the Economic vertical form fill seal packing machine (VFFS), please contact our sales team. We can provide measured energy reports, MTBF/MTTR data from similar installations, and a recommended spare parts kit to meet your uptime goals.

Authoritative references

- Vertical form-fill-seal machine — Wikipedia: https://en.wikipedia.org/wiki/Vertical_form-fill-seal_machine

- PMMI (Packaging Machinery Manufacturers Institute): https://www.pmmi.org/

- International Energy Agency (IEA) — Energy efficiency resources: https://www.iea.org/

- U.S. Food & Drug Administration (FDA) — Equipment and Facility Guidance: https://www.fda.gov/

- Occupational Safety and Health Administration (OSHA) — Machine Guarding: https://www.osha.gov/

Reduce Product Giveaway with Precision Weighing JW-B23

Troubleshooting common issues with a 14 head multihead weigher

Packaging Material Compatibility for Vertical Packaging Machines

The latest trends for 10 head multihead weigher

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

Automatic Multi-Function Pouch Weighing and Packing Machine – 65 BagsMin for Efficient Packaging

The mini combined weighing and packaging machine integrates a miniature multi-head scale with a vertical packaging machine, all controlled by an advanced PLC program. This fully automatic system handles metering, filling, bag-making, date printing, and packaging output. Ideal for weighing small particles such as Chinese herbal medicine, tea, seeds, monosodium glutamate, chicken essence, coffee beans, chocolate, and more. With its affordable price, low maintenance costs, and high efficiency, the mini combined weighing and packaging machine is an economical choice for small-scale operations.

Mini Combined Weighing and Packing Machine with Multihead Weigher for Tea Powder, Coffee Beans, and More

The mini combined weighing and packaging machine integrates a compact multi-head scale with a vertical packaging machine, all controlled by an advanced PLC program. This fully automated system handles precise metering, filling, bag-making, date printing, and packaging output. Ideal for weighing small particles such as Chinese herbal medicine, tea, seeds, monosodium glutamate, chicken essence, coffee beans, chocolate, and more. The mini combined weighing and packaging machine is cost-effective, economical, and offers low maintenance costs, making it an excellent choice for small-scale packaging operations.

Standard Vertical Weighing And Packaging Machine For Granules Puffy Foods JW-B1

Discover Kenwei’s Standard Vertical Weighing And Packaging Machine For Granules Puffy Foods. This efficient vertical packaging machine accurately weighs and packs a variety of foods, making it the ideal weighing and packaging machine for granules and puffy snacks.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei